No products in the cart.

7 surprising effects when investing in laser welding machines for businesses

Recently, the use of laser welding machines is becoming a new trend in the modern manufacturing industry. Leading the way in providing welding equipment and solutions in Vietnam, Weldcom Industrial Joint Stock Company has launched 2 Weldcom laser welding machines LW1000 and LW1500 to the market to catch up with this trend. So what advantages does laser welding equipment possess compared to traditional ones, let’s find out in the article below.

1. Introduction of laser welding machine

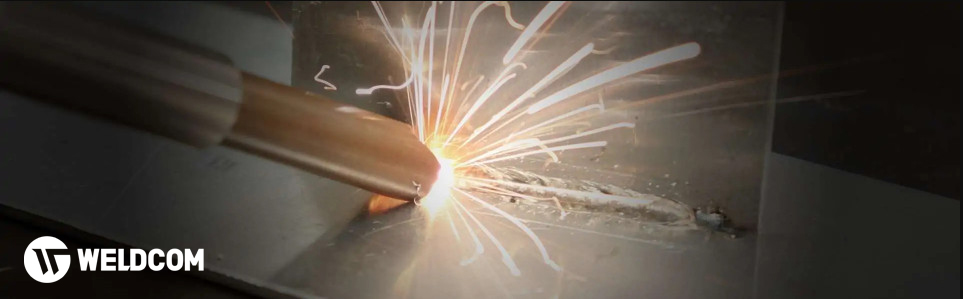

Before learning about the advantages of laser welding, you first need to know what laser welding is. According to Weldcom, a laser welding machine is a device that uses a fiber laser beam focused on a certain area to melt two materials together to create a strong bond between them.

Công nghệ máy hàn laser

The highlight of laser welding is that there is no need for primer and welding rods, but it is still possible to weld large gaps, bringing high aesthetics to the weld.

>> Xem thêm: TIP 6 LƯU Ý CHỌN MÁY HÀN LASER CẦM TAY DÀNH CHO DÂN CƠ KHÍ

2. What are the benefits of laser welding compared to traditional methods?

In what aspects does the laser welding machine show outstanding advantages over traditional methods? Weldcom would like to give some factors such as:

- Welding speed and productivity: It is undeniable that laser welding gas will produce a welding speed 3.5 times faster than solder, while still ensuring the quality of the weld. Therefore, for businesses in the sheet metal processing industry or thin tube boxes, the use of laser welding machines will give high productivity and production costs many times lower, compared to traditional Tig welding methods, Mig welding

- Weld quality: Laser welding machine has many modes for different welding purposes. For example, currently, Weldcom is providing LW1000 and LW1500 laser welding machines with integrated Quilin control and high-end welding gun, allowing users to choose many different laser beam modes such as spot welding, horizontal welding. , single circle welding, double circle welding, single triangle welding, quenching triangle welding, semicircular shape. Besides, the machine can give welds ranging from 0.2 mm to 5 mm.

- Complementary materials: In terms of complementary materials, laser welding does not need to compensate for additional materials during welding. However, if the weld has a large gap or requires additional material, the Lw1000 and LW1.500 welders include an additional set of automatic welding wires to compensate for the missing positions.

- Optimizing labor costs: An outstanding advantage of laser welding is to optimize labor costs. With the Tig welding method, it requires a highly skilled welder to create a beautiful quality weld. In contrast, laser welding only requires an ordinary welder, an unskilled laborer can also create a highly aesthetic joint. Therefore, the use of a laser welding machine will save ordinary labor costs about 40% compared to the salary of skilled workers.

Using Weldcom laser welding machine helps to optimize labor costs

- Welding treatment: Laser welding saves time and labor costs to process welds. Because this method gives high aesthetic value, it does not take time to clean the material and the weld after welding. In addition, the laser welding method for welding joints has extremely small deformation due to high concentrated energy, low energy loss, which helps the ratio between the depth of penetration and the width of the weld to be up to 10/1, giving The energy loss level is at least compared to conventional welding.

- Productivity when using a laser welding machine will be many times higher than that of other welding methods, so depreciation costs and equipment depreciation rates are also significantly lower.

- Usually, the investment cost of a laser welding machine will be higher than that of other welding machines. However, if comparing the advantages of laser welding machines in all aspects like Weldcom just mentioned above, it can be seen that the use of this “master welding” will meet the high requirements of productivity, finished product quality, optimize production costs and improve competitiveness.

In addition, the laser welding machine when used will produce less toxic smoke, does not cause eye fatigue, is safe and friendly for the operator; The weld after using laser welding will not be deformed, has a solid structure and is difficult to break; The weld seam is smooth and beautiful, helping you to reduce further grinding when the finished product is finished.

3. Should you invest in a laser welding machine for your business?

With the above advantages of the laser welding machine that Weldcom pointed out, you must have an answer whether to invest in a laser welding machine for your business. The speed is 3.5 times faster than Tig welding that produces beautiful and smooth welds, optimizes labor and production costs, laser welding machines will be a great choice for your business in the face of today’s demanding requirements. The higher, the customer’s practice.

Weldcom laser welding machine possesses advanced modern technology

Currently, Weldcom is one of the leading units specializing in providing reputable laser welding machines in the market. Along with the integration of current leading technologies, Weldcom LW1000 and LW1500 laser welding machines always achieve stability with high production efficiency, and reasonable prices to serve customers in need. Therefore, if you are looking to buy a laser welding machine, please contact Weldcom immediately according to the information below for specific support. Investing in innovation and development is the right direction for the current context.

Contact information: WELDCOM INDUSTRIAL JOINT STOCK COMPANY

Hotline: 1900 9410

Website: weldcom.vn

Address: 285A Ngo Gia Tu, Long Bien, Hanoi

Tiếng Việt

Tiếng Việt