No products in the cart.

How to operate Weldcom laser welding machine easily and effectively

Possessing many outstanding features and advantages, Weldcom laser welding machines are currently loved and accepted by a large community of mechanical enthusiasts. However, many people have concerns that this advanced equipment requires a lot of knowledge as well as operating experience. In this article, we will learn how to master the Weldcom laser welding machine for readers to refer to the application.

1. Reasons you need to know how to operate a laser welding machine

Laser welding machine is one of the leading high-tech and advanced machines today and is highly sought after by plate processing enterprises in Vietnam. Possessing many benefits and features, but in the process of use, if we do not know how to operate, unpredictable consequences may occur such as:

Imagine, a laser welding machine integrated with many welding mode features. In case we do not know how to operate and adjust reasonable parameters, the inevitable consequences will occur when the workpiece and the welding mode will be incompatible, greatly affecting the aesthetics and quality of the workpiece weld. . From there, users will have an incorrect view of the product when they have to spend a large amount of money to invest but do not meet expectations.

Operating the laser welding machine for good operation is essential

In addition, improper operation will cause the machine to run unstable, causing the above components in the machine to overheat, causing damage, leading to users having to spend more money to repair the device.

With the above, the operation to use the laser welding machine is essential.

2. Weldcom laser welding machine installation and operation manual for new users

To help readers understand specifically how to install and operate, the product models that Weldcom would like to choose for guidance will be LW1000 and LW1500.

2.1. Weldcom laser welding machine operation

When a customer owns a Weldcom laser welding machine, parts such as a Raycus welding source, a cooling system and a Quilin welding gun are already installed by the company. In addition, there are additional sets such as welding tip protectors, wire compensators, wire feed rollers and connection wires. Operation will be through the following steps:

Step 1: Before connecting to the power source, make sure that the power source you use is compatible with the Weldcom 1 phase 220V laser welding machine to avoid the source of the fire.

Step 2: After you have connected the power source, turn on the rear aptomat to start the machine. Next, we proceed to adjust the keys on the function screen in turn, which are the Emergency buttons, the cooling system and wait 30 seconds for the cooling water to have pumped the cooling water to the welding source.

Technical staff operating manual Weldcom laser welding machine

Step 3: Finally, we will turn on the laser welding power button to end the operation.

2.2. Weldcom laser welding machine installation

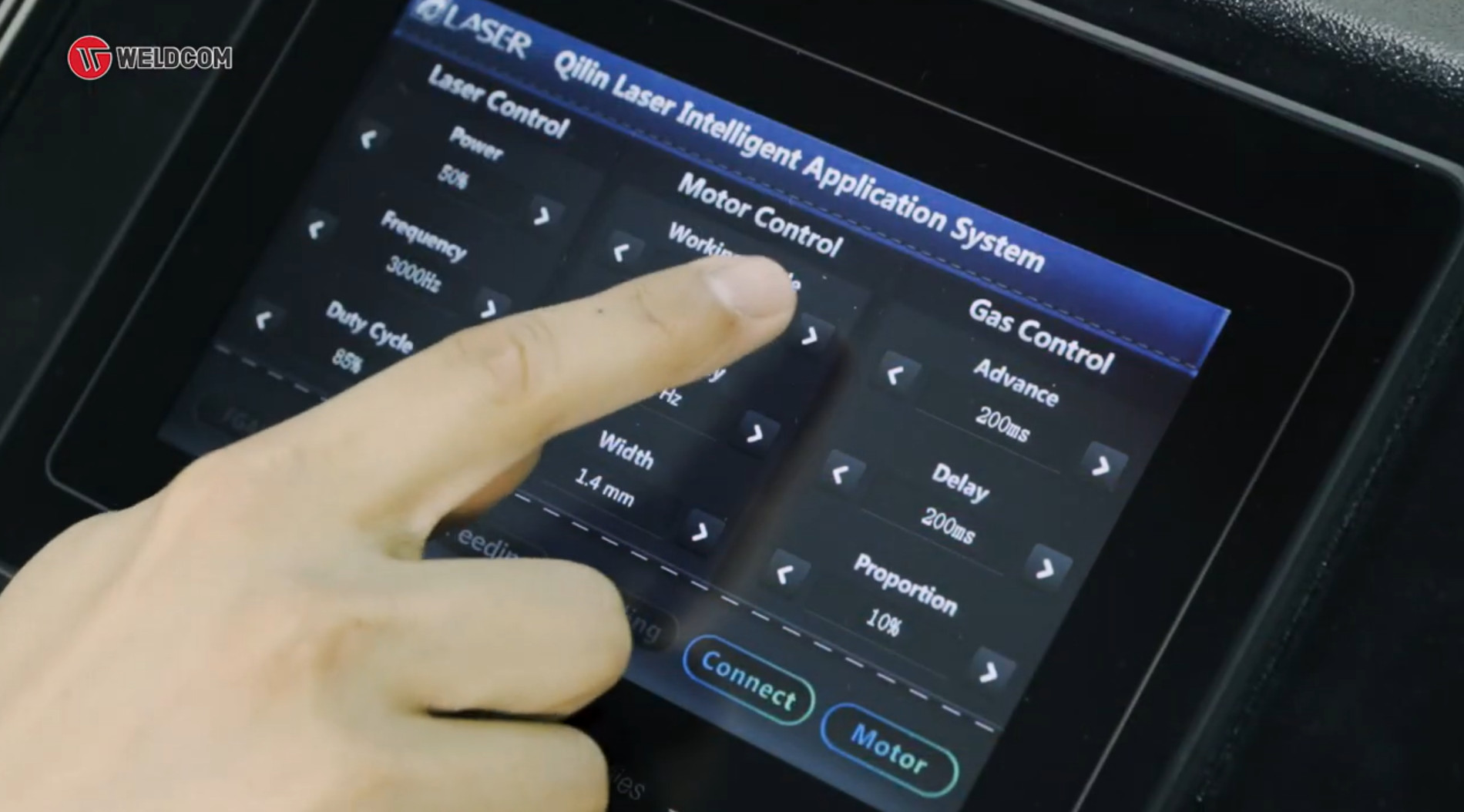

After starting the machine, the screen device on the Weldcom laser welding machine will be displayed, helping you to conveniently adjust the position on the spot. In addition, the touch screen of the Weldcom laser welding machine is integrated with many languages, displaying Vietnamese by default to help you easily set parameters when deploying. On the screen, there will be 3 areas for us to install specifically:

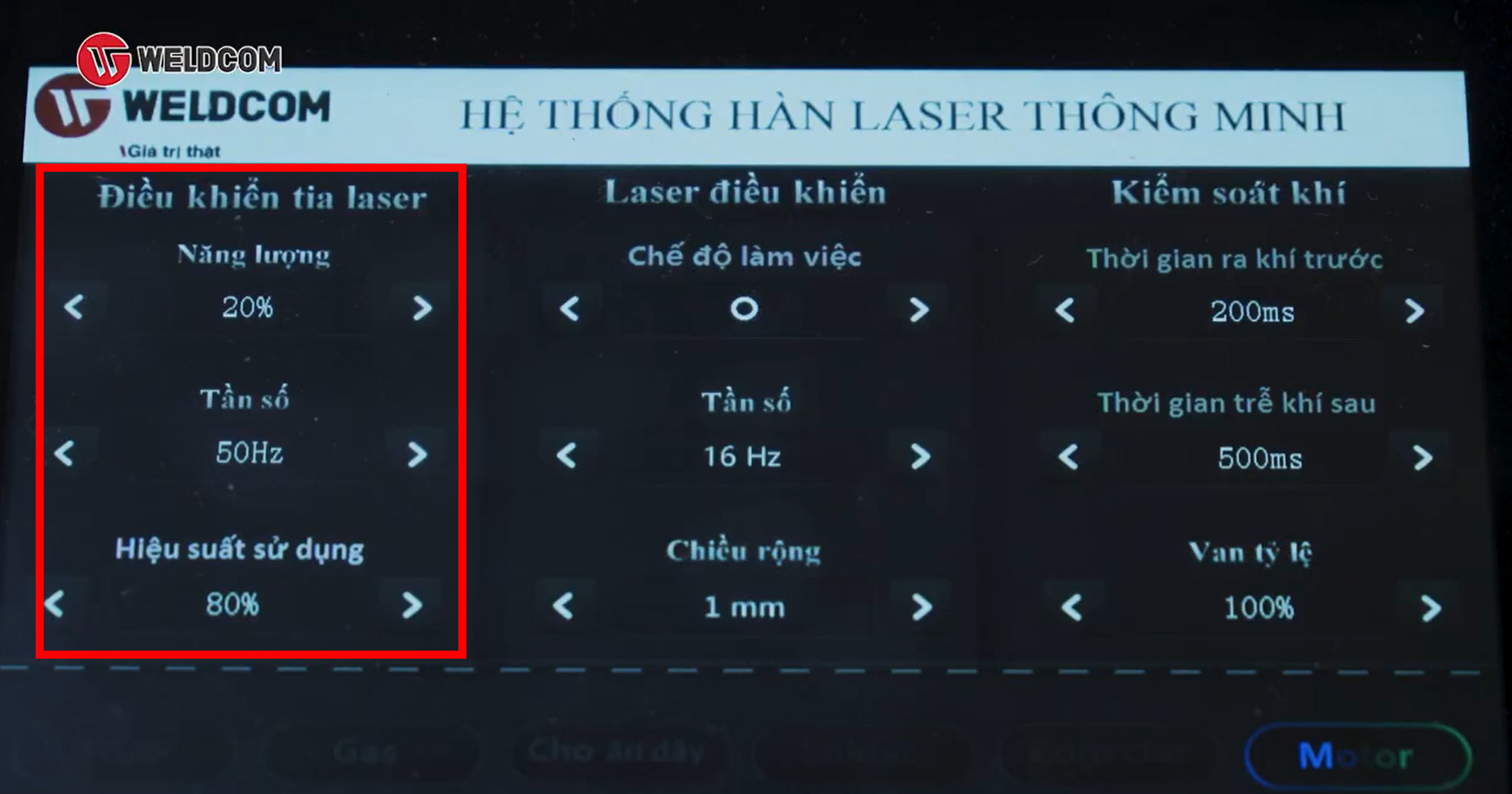

The first area on the left side of the screen is used to control the laser or set up parameters on the source, including parameters such as power level (high level is used to weld thick workpiece details, and vice versa for thin plate welding. The second parameter is the laser output frequency of the welding source in 1 second, you can set it from 50 Hz to 30000 Hz depending on the workpiece material.

Laser control area

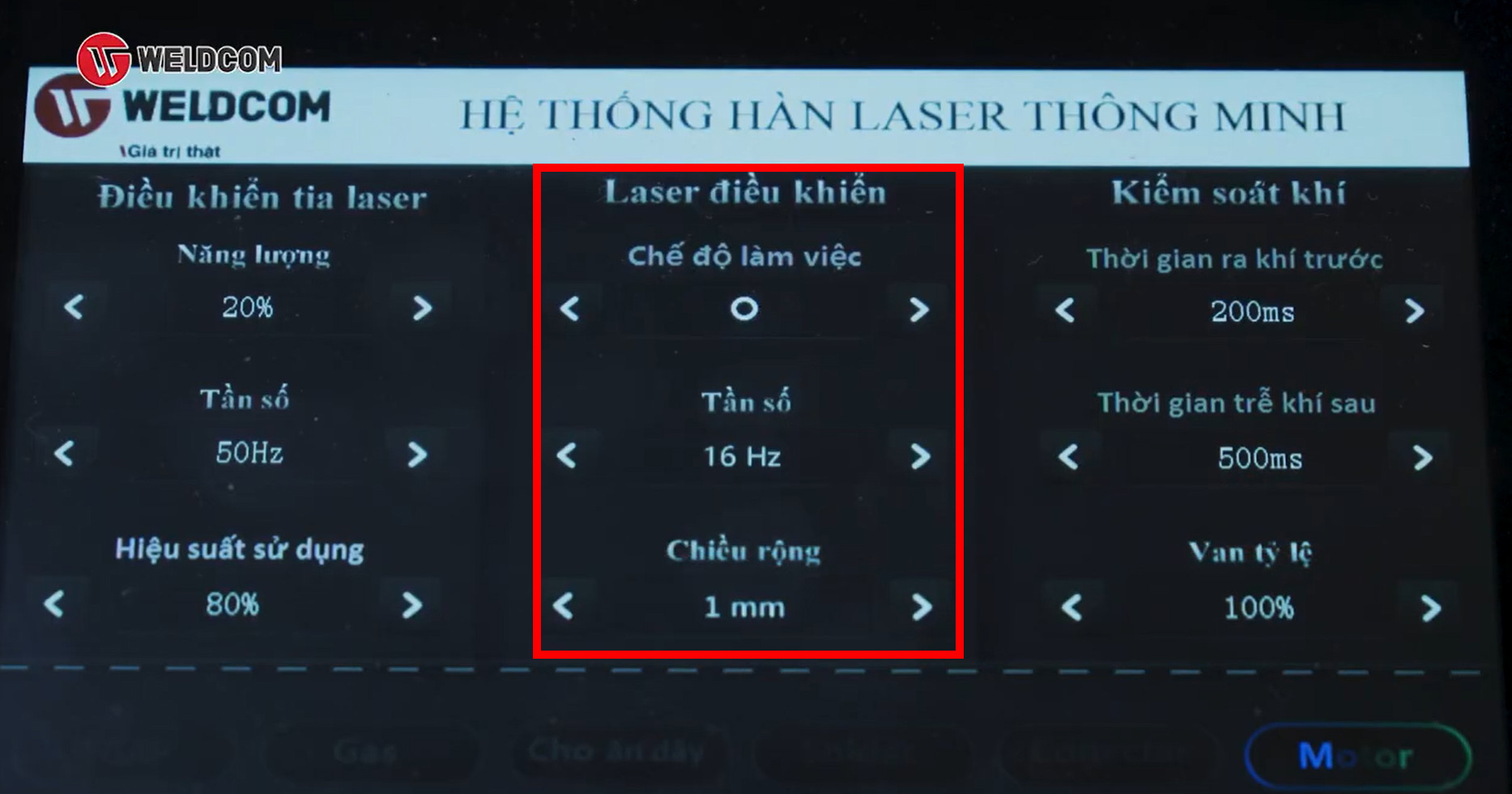

- The second area is used to control the Quilin welding gun, denoted by “laser control” that integrates parameters such as the welding gun working mode divided into 7 features for users to choose such as punch welding, line welding, welding. single circle, double round welding, single triangle and double triangle, semicircle line. The second factor is the oscillation frequency of the lens axes on the Quilin welding gun to create the working modes. The remaining parameter is the width to adjust the width of the laser welding beam.

Controlled laser area

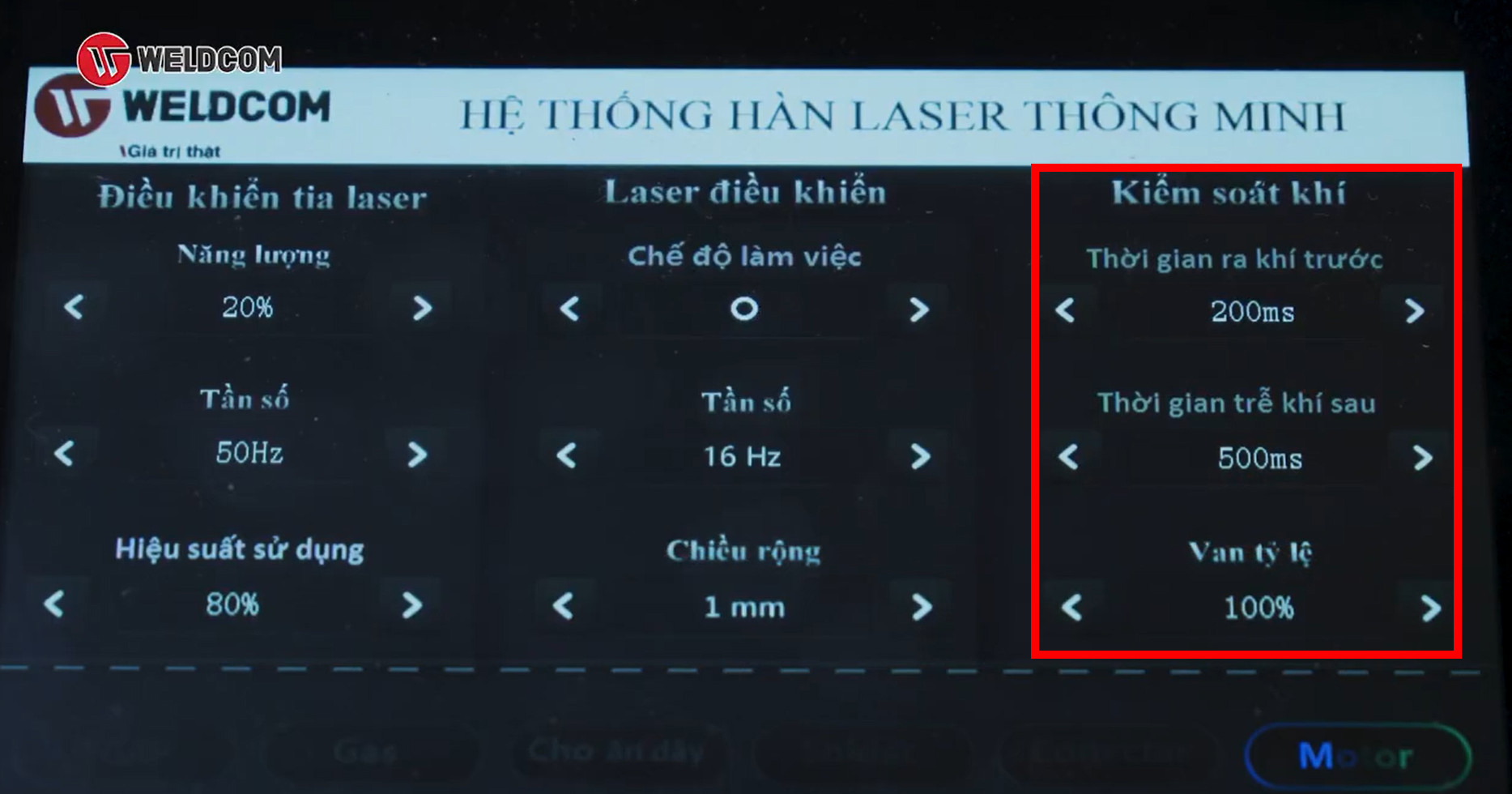

- The final setting area located in the right corner of the screen is “gas control” which helps to adjust the pre-air release time and the post-weld delay time. The above two parameters have an important function to protect the prism on the Quilin welding gun from overheating.

Gas control area

3. Notes when using laser welding machine

Above are the instructions for operating and installing LW1000, LW1500 laser welding machines that Weldcom would like to share for your reference. However, in the process of use, in order for the welding machine to work most stably and avoid damage, you need to pay attention to the following issues:

- Using a laser welding machine a lot with large capacity will lose the cooling water level, causing the machine to heat up. Therefore, always check and make sure the cooling water level is in the green zone, it is recommended to use double distilled water for cooling.

- Before using the machine, increase the exhaust time parameter before welding and after welding to protect the lens on the Quilin welding gun.

- After each shift, check the protective prism on the welding gun to make sure the lens is clean and free of impurities or dirt. In case if the lens is dirty, absolutely use dirty hands or a towel to clean it.

- Use the correct tip for the type of connection you are using.

- To ensure a beautiful and high-accuracy weld, you should check that the wire feeder including the wire feed roller and the compensator tip is suitable for the wire diameter.

In the process of using Weldcom laser welding machine, if you find it difficult to operate and install, please contact us immediately for specific advice and support. Currently, Weldcom has owned a network of technical service centers at key dealer systems and showroom branches nationwide, with a team of skilled technical staff who will advise and answer all questions in detail. your problem.

Contact information: WELDCOM INDUSTRIAL JOINT STOCK COMPANY

Hotline: 1900 9410

Website: weldcom.vn

Address: 285A Ngo Gia Tu, Long Bien, Hanoi

Tiếng Việt

Tiếng Việt