- Production technology and quality management according to the standards of Nisshinbo – Japan.

- Servo motor generates punching force for fast speed, can reach 1500 times/min.

- Turntable punching station, made of hardened alloy steel, precision machined.

- Thick punching plate, suitable for common punches and dies, servo motor control, precise positioning, flexible operation.

- The punching station integrated with the Auto-index head allows punching to form many complex details.

- Exclusive Auto-index punching control technology, for high positioning accuracy.

- The workpiece moving system consists of two CNC X and Y axes driven by a servo motor through a ball screw.

- Powerful control function with 840D CNC control system from Seimens-Germany.

- Touch screen HMI 17inches, easy to operate.

- Precise head down control, maximum error only ±0.01.

- Equipped with probe sensor and workpiece clamp sensor.

- Energy saving, low operating cost, low noise, simple maintenance.

- Integrating the world’s leading Sigmanest billet stacking software, maximizing material savings.

- New industrial design with simple style, beautiful appearance and generous appearance

- Better parameter ratio, better core configuration, stable performance and convenient operation

- High-rigidity frame, automatic control of mechanical deflection of workbench for precise bending

- Yawei’s high-quality hydraulic press is a line of high-quality hydraulic presses with modern features and European design style.

- DA53T CNC controller from Delem Netherlands.

- Advanced hydraulic system Hawe – Germany, oil pump of Voith/Eckerle (110T) – Germany, improve stability, trust the hydraulic system.

- The main motor is a servo motor to help increase speed, limit noise, save power, minimize oil leakage errors on the hydraulic system, limit the increase of oil temperature when working to help maintain regime stability.

- The working table is equipped with a CNC-controlled hydraulic compensation system, limiting the sagging state when the product coupling is long.

- As standard, there are 2 CNC axes (X, R) which are powered by AC servo motors, which are switched by high precision speed conversion shaft.

- Safety for everyone is thanks to the safety door on both sides and back of the machine.

- Many upgrade options, well combined with robots.

- Yawei’s most advanced trauma machine series with many modern features, high accuracy and speed of injury.

- Delem DA53T controller – Netherlands, 2D programming display and setup. Hydraulic system Rexroth or Hawe – Germany, oil pump brand Rexroth or Voith/Eckerle – Germany.

- The main motor is a servo motor to help increase speed, limit noise, save power, minimize oil leakage errors on the hydraulic system, limit the increase of oil temperature when working to help maintain regime stability.

- The working table is equipped with an automatic mechanical control compensation table by CNC to thoroughly solve the display of hammock products.

- After standard, there are 2 CNC axes (X, R), driven by AC servo motor, moving by ball motor.

- Equipped with a convenient quick-change tool connection system that removes tools directly at each position with ease.

- The moving frame system on the slide helps to adjust the distance to zoom out easily and quickly.

- Effectively combined with robots, many advanced options according to customer requirements.

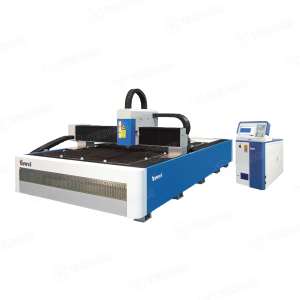

- Single-table machine, without guards, effectively cuts thin metal sheets, suitable for materials ≤ 12mm thick. …

- Imported fiber laser source, long life, low maintenance cost, fuel-saving and environment-friendly.

- The machine structure is neat, saving warehouse space, convenient for all levels of work, districts and manipulation when operating.

- High-end accessories such as German brand IPG laser source, Raytools – Switzerland cutting head, rack, gears and gearboxes from Japan, Sweden.

- Equipping the whole machine with voltage stabilizer and automatic lubrication system

- Meets the precision standards of the sheet metal processing industry.

- Latest design, high performance, world standard high speed laser cutting machine version.

- Safe operation, clean environment meets European standards.

- Mechanical structure, strict production standards. X-axis machined by alloy steel for high travel speed and withstand large torque and acceleration.

- The control system, driver, and Siemens synchronous motor provide precise control, anti-interference and high stability.

- Inheriting the perfect development of HLF features for the best cutting quality and punching ability.

- Equipped with the latest technology and features for easy fault diagnosis, maintenance and operation.

- Easy integration of 4.0 smart factory solutions.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- The new generation design follows the HLE model, bringing a wide range of options to the high-end segment lasers.

- Beckhoff controller; driver, servo motor, Physic driver or option of famous brands.

- Solid mechanical structure, high production standards, system of moving parts from high-end brands.

- Alarm system, easy maintenance and operation.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- The design promotes efficiency, economy, reasonable and optimal machine structure.

- Gate structure with two parallel moving rails, two switching workbenches improves productivity, high speed with 2.1G acceleration.

- Fiber laser transmission, no mirror system, so the cost of operation and maintenance is very low, working reliably and stably.

- The chamber protects the main cutting table area, limiting smoke and dust.

- The sight glass is anti-laser and provides high safety for operators.

- Imported components, long life and stability: Beckhoff controller – Germany, IPG laser source, Raytools cutting head – Switzerland…

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- Quality meets European standards, is rated as China’s No.1 laser cutting machine product.

- New styling with marked improvement in cutting performance.

- High performance, high speed, acceleration reaches 2.0 – 2.8G.

- Gate-shaped machine structure, parallel two-rail movement, moving beam made of monolithic aluminum alloy, conversion table allows double working productivity, working table height is always kept at a fixed level thanks to the mechanism. hydraulic lift.

- High-end accessories: IPG laser source, Precitec cutting head, Siemens controller, Schneider electrical components

- Super fast cutting speed for thin materials, stable cutting for medium and thick materials.

- The combination of laser angle cutting technology and advanced numerical control technology, accompanied by a humanized HMI interface and an upgraded professional laser cutting database.

- Automatically adjust air pressure, cutting power, cutting speed according to material thickness.

- Automatic calibration feature allows good cutting of warped sheets.

- Automatic cutting head cleaning feature.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- Single desk

Metal sheet cutting, metal pipe not available

1.5kw / 2kw / 3kw / 4kw available

Tiếng Việt

Tiếng Việt