YTB – 6020 Yawei CNC Laser cutting machine

- (0 customer reviews)

- Write a product review

- Print this page

Introduction to YTB-6020 optical fiber laser pipe cutting machine

- Advanced technology and process to achieve pipe batch efficient processing

- High rigidity mechanical structure, advanced caliping system, intelligent auxiliary stock, high efficiency and high quality cutting guarantee

- The deep integration of digital control system, precision transmission components and laser application technology goes beyond various traditional pipe processing methods

- Fully protective brand new look, professional pipe cutting software

CNC laser pipe cutting machine is a professional pipe cutting and processing products, compared with the traditional pipe saw cutting, milling, plasma cutting and other processing methods, CNC laser pipe cutting machine has fast speed, high accuracy, good flexibility and many other advantages. Its main technical features are as follows:

- Design

After years of research and development and innovation, the integration of advanced laser technology, the introduction of Italian imported cutting process, optical fiber transmission, suitable for cutting all kinds of complex parts, powerful CNC system and programming software to solve many process problems, to further improve the cutting accuracy, perforation speed, simple and convenient operation.

TFB series optical fiber laser tube cutting machine uphold the simple and practical design concept, give full play to the advantages of optical fiber transmission, combined with mature control software, perfect functions, stable product performance.Powerful cutting function, can simultaneously cut square pipe, round pipe, rectangular pipe and various different types of pipe.Optional automatic feeding, good openness, convenient and simple operation

- Manufacturing process

More than 60 years of machine tool processing experience with advanced processing equipment guarantee: in product manufacturing link, wei has advanced processing, testing, measuring equipment more than 300 sets, imported floor boring and milling machine, CNC gantry and vertical machining center and other main CNC precision efficient and large machining center more than 100 sets, three coordinate meter, laser interferometer and other kinds of precision testing instruments more than 30 sets.

- Inspection process

Yawei Chuang Keyuan adheres to the development strategy of winning by quality, Continue to promote the quality management of the whole staff and the whole process, Always adhere to, “three press”, “three inspection”, “Three no” and other quality systems and principles- – “three press” —— according to drawings, according to process documents, according to technical standards; Process control adhere to the “three inspection system” —— self-inspection, mutual inspection, final inspection; Physical quality adhere to the “three no” —— does not receive bad products, do not produce bad products, do not outflow of bad products; Out of the quality problems adhere to the “three not let go” —— did not analyze the reasons, did not find out the responsible person, did not take corrective or preventive measures did not let go; Continue to carry out quality breakthrough and QC activities according to the PDCA cycle management method to promote quality improvement, Constantly extend the quality management to both ends (supply side and client end).

- Technical process

From CO2 laser cutting began in 2006,3 D fiber laser cutting in 2008 developed to now includes laser cutting, welding, cladding, quenching and other complete laser solutions.

More than ten years of laser technology, technology research and development and innovation, more than 100 technical process team, and the introduction of Italian cutting-edge laser cutting technology, the use of well-known cutting software, forming a perfect process database, with the call, to ensure the cutting speed and effect.

The machine tool overall cutting speed is faster and the cutting effect is better.

- Accuracy and efficiency

Bed body using overall welding structure, after annealing treatment can eliminate welding stress, good rigidity, high accuracy, ensure long-term use without deformation; beam using lightweight material after heat treatment, high precision machining, high precision, equipped with high rigidity precision reducer, grinding gear rack and other efficient transmission mechanism, equipped with fiber laser through mature and advanced system integration, faster, higher efficiency, to meet the needs of different industries and customers.

Uniaxial acceleration of 1G, to achieve high efficiency processing.

- After-sales service and service

Perfect marketing service network: Yawei deeply cultivates market segments, has built more than 50 offices integrating sales and service in China, and has established sales agencies in more than 40 foreign countries;

Adopt CRM information means, realize the whole process of pre-sale, sale and after-sale information management, provide customers with thoughtful and timely service, and win the long-term favor and trust of domestic and foreign customers;

Customers can contact us in the first time through telephone, wechat scanning code and other methods, implement the first ask responsibility system, and solve the problem in the first time;

While dealing with the repair problems, check the machine comprehensively and provide equipment preservation service; customer equipment full life cycle management, customer zero trouble is our pursuit.

Technical Parameters

| Order number | name | Parameter | unit |

| Pipe processing range (long x pipe diameter) | |||

| 1 | Scope of processing pipe (long x pipe diameter)

| 6000×φ 20-φ 210 6000×□20-□150 | mm |

| 2 | X axis stroke | 6500 | mm |

| 3 | Y axis stroke | 200 | mm |

| 4 | Z axis stroke | 240 | mm |

| 5 | A, B axis stroke | Infinite rotation | |

| velocity | |||

| 6 | The X / Y axis maximum speed | 90 | m/min |

| 7 | Maximum rotation speed of the A / B shaft | 90 | r/min |

| 8 | The X / Y axis has a maximum acceleration | 0.8G | m/s² |

| accuracy | |||

| 9 | positioning accuracy | ±0.05 | mm |

| 10 | Repeat positioning accuracy | ±0.03 | mm |

| Loading specifications | |||

| 11 | Length of feeding pipe | 3000-6200 | mm |

| power requirement | |||

| 12 | Power supply rated voltage | 380 | V |

| 13 | number of phases | 3 | Phase |

| 14 | frequency | 50 | Hz |

| laser | |||

| 15 | The central radiation wavelength | 1070-1080 | nm |

| 16 | Transmission fiber diameter | ≥50 | μm |

| 17 | Laser power | 3000 | W |

| Weight and size | |||

| 18 | Maximum pipe weight | 200 | kg |

| 19 | Machine dimensions (L W H) | 9300 ×4000×2400 | mm |

The equipment processing capacity

Processing scope of pipe materials

| cast | range of work | Raw material maximum length |

| circular tube | Φ20– Φ 210mm | 6200mm |

| square pipe | 20-150mm | |

| rectangular tube | 20-150mm |

Pipe processing capacity

| material | Pipe wall thick (Power: 3,000 W) |

| carbon steel | 1-10mm |

| stainless steel | 1-6mm |

| alufer | 1-5mm |

| yellow metal | 1-4mm |

Note: 1. The maximum processing scope of the rectangular pipe is 150mm for the long side side length, and the processing range of the round pipe and the square pipe is shown in the table above;

- If you need to cut the pipes other than the above table, such as I-shaped steel, please contact the product manager.

- If cut pipe for a long time, it is recommended to purchase our YTF model.

- The distortion and bending of the pipe shall not be lower than the allowable deviation in GB / T 6728-2002.

Main configuration

| order number | name | brand |

| 1 | machine tool | The YAWEI 6020 pipe-cutting machine tool |

| 2 | laser generator | Raycus/MAX 3000W,CHINA |

| 3 | Laser cutting head components | YAWEI |

| 4 | numerical control system | YAWEI |

| 5 | Servo motor and drive | INOVANCE,CHINA |

| 6 | Electric-gas ratio valve | Japan SMC |

| 7 | gear wheel | DESBOER,JAPAN |

| 8 | rack | LINDEN,SWEDEN |

| 9 | reduction box | DESBOER,JAPAN |

| 10 | Precision straight line guide rail | PMI,CHINA |

| 11 | Precision rolling bead wire rod | PMI,CHINA |

| 12 | cooling-water machine | TONGFEI,CHINA |

| 13 | Laser regulator | YAWEI,CHINA |

| 14 | crossbeam | YAWEI,CHINA |

| 15 | drag chain | standard |

| 16 | Special card plate | YAWEI Auto Chuck |

| 17 | Finished loading platform | None (optional 3000mm drop) |

Bed body beam plate

- Steel structure welding bed body, large return furnace overall annealing to eliminate internal stress, good rigidity, stable without deformation.

- High strength, beam body lightweight design, very low deformation

- Imported large CNC equipment processing, to ensure the position and size of the installation surface, to achieve the accuracy beyond the design standards.

- The upper guide rail structure protects the guide rail from laser processing splashing and extends the service life of the machine.

- Equipped with drawer discharge trolley to remove workpieces and waste.

- The beam adopts lightweight pipe structure, rough processed after annealing eliminates internal stress, and refined after secondary vibration aging treatment, which better solves the stress caused by welding and processing, thus greatly improving the stability of the machine tool.

- Mobile dial can drive the pipe along the Y axis of the machine, to achieve rapid movement and feeding;

- The chuck rotation shaft is driven by the servo motor, with high accuracy and fast movement.

Software introduction

More than ten years of laser process research and development and innovation, the introduction of Italian cutting-edge laser cutting process, equipment using domestic well-known cutting software, good cutting speed and effect.You can provide parameter settings, custom cutting process editing, simulation, sorting, and idling and processing.

Gas road and waterway

Compressed air cutting air circuit diagram (air compressor selection)

- Cutting gas is divided into three gases: nitrogen, oxygen and air, different materials to choose different cutting gas, improve the cutting quality and cutting efficiency;

- Can use air cutting carbon steel thin pipe and stainless steel, aluminum alloy plate, for customers to greatly reduce the processing costs.

- If air cutting is often used, in order to achieve better cutting effect, users are recommended to add a cold dryer (as shown in the figure above); the cold dryer can force the compressed air below the required dew point, thus condensing a large amount of water vapor and oil mist contained into liquid droplets, separated by gas and discharged by the drain to dry the compressed air.

- The waterway system includes two parts: part of the cooling water comes out of the cooler, enters the laser, cools the radiator through the laser radiator inside, and returns to the cooler; part of the cooling water comes out of the cooler, enters the laser cutting head part for cooling and returns to the chiller.

Laser source

- Optical fiber laser electrical-optical conversion efficiency is high, the conversion efficiency of more than 30%, medium power optical fiber laser using water cooling, can greatly save the power consumption at work, save the operating cost, to achieve high production efficiency

- Laser operation only needs electric energy, does not need to produce additional gas of the laser, with low operation and maintenance costs;

- The output wavelength of the optical fiber laser is 1.07 micron, is 1 / 10 of the CO2 wavelength, the output beam quality is good, high power density, is conducive to the absorption of metal materials, has a good cutting ability, so that the processing cost is low;

- The whole machine optical route by optical fiber transmission, does not need a complex mirror and other light guide system, simple light road, stable structure, external light road maintenance-free

Fiber-optic laser-cutting head

- Highly dustproof

Fully enclosed wrapped light road, the possibility of lens pollution is almost zero.

The laser energy is not affected, and the light transmission is more stable, reducing the cleaning into

- GIF zero focus

The scale can be flexibly adjusted, so that the zero focal position is unified, no longer to adjust the process parameters trouble.

- High efficiency water cooling

Focus mirror, collimator mirror, nozzle are built-in cooling function, strong to solve the problem of cutting heating.Maximize the service life of the cutting head and increase its continuous working time.

- Optimize structural design

Integrated body design, the improved QBH optical fiber interface is no longer stuck due to water leakage, rust and other reasons.

Equipped with various belt QBH connector laser.

- The focus mode

Manual focus / autofocus

Chiller

Using the same fly brand of optical fiber laser special chiller cooling laser

- (1) Electrostatic injection plastic shell, beautiful and generous, the surface plate adopts the form of rapid disassembly, convenient to use and maintenance;

- (2) High efficiency and energy saving, high control accuracy, using PID intelligent temperature control, temperature control accuracy can reach ± 0.1℃;

- (3) Remote control, convenient operation, the whole series is equipped with RS485 communication function;

- (4) High reliability, long life life;

- (5) Intelligent control and anti-freezing protection. After the anti-freezing protection is opened in winter, the chiller will enter the intelligent control and anti-freezing protection;

- (6) Multiple alarm protection, making the water cooler operation safe and reliable and high;

- (7) The cutting-edge double water temperature design is adopted to effectively protect the normal operation of the water cooler;

- (8) Double water filter protection, special pipe material, can effectively prevent impurities

Scope of supply

Product configuration

| order number | name | model | quantity | remarks |

| 1 | main machine | YTB-6020 | 1 set | YAWEI |

| 2 | laser | MAX -3000 | 1 set | MAX,China |

| 3 | cooling-water machine | standard layout | 1 set | Tongfei,China |

| 4 | Cuttting head | Manual focus,Raytools, (optional:Auto focus) | 1 set | YAWEI |

| 5 | CNC Controller | YAWEI | 1 set | YAWEI |

| 6 | Dust fan | standard layout | 1 set | standard |

| 7 | CNC chuck system | standard layout | 1 set | YAWEI |

| 8 | stabilized voltage supply | standard layout | 1 set | standard |

Standard spare parts

| order number | name | quantity | remarks |

| 1 | cutting torch | 10 Only | |

| 2 | Protect the lens | 5 Only | |

| 3 | attachment tools | A set |

Technical data

| order number | name | quantity | remarks |

| 1 | Instructions for laser pipe cutter | A | |

| 2 | Laser operating manual | A | |

| 3 | Electronic version of CNC System Data | A | |

| 4 | Electrical schematic diagram | A | |

| 5 | Water cooling machine instruction manual | A | |

| 6 | Product Installation Layout Drawing | A | |

| 7 | Product Delivery Certificate | A |

Technical Supplementary Instructions

| 1 | The processed pipe shall comply with the relevant provisions of the national standard of Cold-bent Hollow Steel for GB / T 6728-2017 Structure. |

| 2 | The processed pipe shall be straight with a curvature of 1mm / 1m (4mm / 6m). |

| 3 | The distortion degree of the processed pipe shall be less than 0.02% of the total length. |

| 4 | For welded pipes, the external weld shall be basically flat, and the height shall be less than 0.3mm, and the internal weld height shall be less than 2mm. |

| 5 | Workpiece machining precision: on the basis of the material error, the position error is IT12, and the shape contour error is IT12. |

| 6 | The roughness of the pipe cutting section varies with the different pipe material and thickness, and the surface of the processed pipe should be free from serious corrosion, otherwise the quality of the cutting section will be affected. |

| 7 | To reduce the cutting effect of pipe deformation, the relationship between pipe thickness and pipe diameter (or outer circle diameter of non-round pipe) is required as follows: When pipe is greater than 50:1 / 40 of pipe diameter thickness 1 / 10 of pipe diameter Pipe material is less than 50:1mm pipe thickness is 1 / 10 of the pipe diameter For bending, twisted deformation exceeding the relevant standard can not guarantee the cutting effect. |

YTB – 6020 Yawei CNC Laser cutting machine

(0 customer reviews)Customers comment on the product

Related products

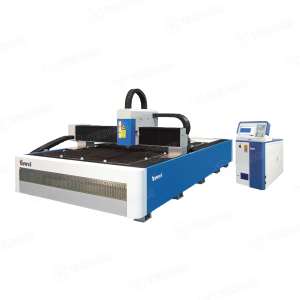

- Single-table machine, without guards, effectively cuts thin metal sheets, suitable for materials ≤ 12mm thick. …

- Imported fiber laser source, long life, low maintenance cost, fuel-saving and environment-friendly.

- The machine structure is neat, saving warehouse space, convenient for all levels of work, districts and manipulation when operating.

- High-end accessories such as German brand IPG laser source, Raytools – Switzerland cutting head, rack, gears and gearboxes from Japan, Sweden.

- Equipping the whole machine with voltage stabilizer and automatic lubrication system

- Meets the precision standards of the sheet metal processing industry.

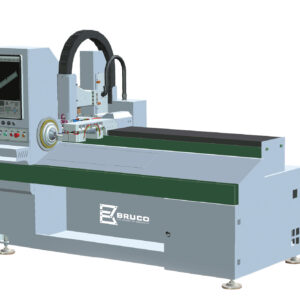

- Suitable for cutting medium and small pipes.

- Efficient cutting with high precision.

- Optimizes investment costs.

- Compact machine size, saves workshop space.

- 2-year warranty.

- Quality meets European standards, is rated as China’s No.1 laser cutting machine product.

- New styling with marked improvement in cutting performance.

- High performance, high speed, acceleration reaches 2.0 – 2.8G.

- Gate-shaped machine structure, parallel two-rail movement, moving beam made of monolithic aluminum alloy, conversion table allows double working productivity, working table height is always kept at a fixed level thanks to the mechanism. hydraulic lift.

- High-end accessories: IPG laser source, Precitec cutting head, Siemens controller, Schneider electrical components

- Super fast cutting speed for thin materials, stable cutting for medium and thick materials.

- The combination of laser angle cutting technology and advanced numerical control technology, accompanied by a humanized HMI interface and an upgraded professional laser cutting database.

- Automatically adjust air pressure, cutting power, cutting speed according to material thickness.

- Automatic calibration feature allows good cutting of warped sheets.

- Automatic cutting head cleaning feature.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- The new generation design follows the HLE model, bringing a wide range of options to the high-end segment lasers.

- Beckhoff controller; driver, servo motor, Physic driver or option of famous brands.

- Solid mechanical structure, high production standards, system of moving parts from high-end brands.

- Alarm system, easy maintenance and operation.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- SF3015G single table fiber laser cutting machine without protective cover is a good choice of customers in the popular segment. Machine for Ability to cut steel, stainless steel, aluminum alloy and other steels;

- Machine frame is annealed and stress treated after welding, machine beam parts are manufactured by cast aluminum.

- The machine is applied in automobile industry, sheet metal industry, furniture industry, advertising industry, etc.

Model: BLC3000

Ray 3.15 x10m (15Kg/m), 1 steam CNC + 1 CNC Plasma (on the same mine lifter), with Sigmanest Companion software, Huayuan HYCC-M3 CNC control system.

Model: BLC4000

Ray 4 x14m (15Kg/m), 1 mỏ CNC hơi+1 CNC plasma (trên cùng một bộ nâng hạ mỏ), kèm phần mềm Sigmanest Companion, hệ thống điều khiển CNC Huayuan HYCC-M3.

- Quick response to control, saving gas, electricity and cost

- Using bright surface cutting technology, fast cutting speed, small slope, low roughness

- Gantry double-drive high-rigidity bed structure, annealing and stress-relieving operation to sensure efficient and stable running

- Humanized operation interface and cutting parameter library are fully upgraded

- Single desk

Metal sheet cutting, metal pipe not available

1.5kw / 2kw / 3kw / 4kw available

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.