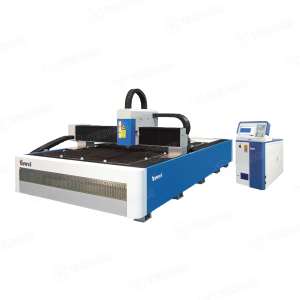

HLE Yawei series Laser Cutting machine

- (0 customer reviews)

- Write a product review

- Print this page

Trademark:

Product code:

Product description:

- The design promotes efficiency, economy, reasonable and optimal machine structure.

- Gate structure with two parallel moving rails, two switching workbenches improves productivity, high speed with 2.1G acceleration.

- Fiber laser transmission, no mirror system, so the cost of operation and maintenance is very low, working reliably and stably.

- The chamber protects the main cutting table area, limiting smoke and dust.

- The sight glass is anti-laser and provides high safety for operators.

- Imported components, long life and stability: Beckhoff controller – Germany, IPG laser source, Raytools cutting head – Switzerland…

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

Introduction to HLE Fiber Laser Cutting Machine

- Good choice for medium and thin plates, the perfect combination of speed and performance, the king of cost performance

- Dual-drive gantry body structure, High rigidity laser welding beam

- Productivity significantly improved by efficient automatic exchange worktable

- Highly integration of laser cutting technology with advanced digital control technology

- User-friendly operation interface and fully upgraded expert parameter library

Technical Parameters

| No. | Name | Parameters | Unit |

| Worktable and work area | |||

| 1 | Processing range (length x width) | 6000×2000 | mm |

| 2 | Travel of X axis | 6040 | mm |

| 3 | Travel of Y axis | 2020 | mm |

| 4 | Travel of Z axis | 240 | mm |

| Speed | |||

| 5 | Maximum synthesis speed of X-Y axis | 140 | m/min |

| 6 | Maximum acceleration of X&Y axis | 2.1G | m/s2 |

| 7 | Height control of Z axis | Numerical control/servo | |

| PRECISION | |||

| 8 | positioning precision | ±0.03 | mm |

| 9 | Repeated positioning accuracy | ±0.02 | mm |

| Power requirement | |||

| 10 | Rated voltage of power | 380 | V |

| 11 | Phase | 3 | Phase |

| 12 | Frequency | 50 | Hz |

| 13 | Complete machine power (not including Air compressor and Dust collector) | 40 | kw |

| Laser generator | |||

| 14 | Central radiation wave length | 1070-1080 | nm |

| 15 | Diameter of transmission fiber | ≥50 | μm |

| 16 | Laser power | 6000 | w |

| Weight and size | |||

| 17 | Maximum load of worktable | 2500 | Kg |

| 18 | Overall weight | 14000 | Kg |

| 19 | Occupation area | 15500×5000×2150 | mm |

Performance characteristics

Advanced technology

Unique CNC control technology

- German original Beckhoff CNC system, customized development of laser cutting function package based on PC control technology, perfect combination of hardware and software; TwinCAT open control framework, using the world’s current highest speed and reliable bus technology, can meet high speed and high precision requirements;

- The cutting head is highly accurate and stable

- Germany Beckhoff CNC system, stable and reliable performance.

- The industrial computer adopts Win7 system

- Number of control axes 3+1 (X1, X2, Y, Z axes)

- Power control function.

- The movement of the machine is controlled by the host interface and the operation panel.

- Power control function.

- High response follow-up cutting function.

- Absolute coordinates and relative coordinates.

- The dry running function of the machine tool.

Handy HMI control technology

- Independent CNC system, non-interference with HMI human-machine interface

- Production planning function, seamless connection with factory MES

- Flexible entry, arbitrary selection of cutting contour

- Integrated IPG monitoring software monitoring function, more effective troubleshooting

- Power control function.

- High response follow-up cutting function

Ingenious mechanical design-frame

- The gantry type steel structure welding bed, the overall annealing of the large tempering furnace eliminates the internal stress, the rigidity is good, stable and not deformed.

- The machine tool adopts the form of integral welding, which is processed and formed by a high-precision gantry machining center imported from Europe at one time, without the need for foundation to ensure the long-term stable operation of the equipment and shorten the commissioning cycle;

- The overall annealing of the welding bed is stress-relieved, and the deformation of the rack surface is ≤25μm.

Unique mechanical design-beam

- The Y-axis beam is a high-rigidity large-section structure, optimized by finite element analysis, light in weight and good in dynamic performance

- The laser beam is welded by steel structure, and then processed by vibration and aging, and then processed to ensure the strength, rigidity and stability of the beam

- An organ-type protective cover is installed on the crossbeam to ensure that the rack and linear guide rail operate in a closed environment and are not affected by the external environment.

Exchanging worktable

- The workbench is an integral welded structure with good strength and stability.

- The exchange worktable is composed of an exchange device and two movable cutting worktables: the exchange device is fixed on both sides behind the bed and the worktable. The exchange speed is fast, and the work area and the exchange area are automatically positioned to ensure repeated processing accuracy.

Z axis device

- The Z axis device is to realize the up and down movement of the cutting head. After the capacitance sensor on the cutting head detects the distance from the cutting nozzle to the surface of the plate, The signal is fed back to the control system, and then the control system controls the Z-axis motor to drive the cutting head to move up and down, thereby controlling the distance between the cutting nozzle and the plate to be unchanged, and effectively ensuring the cutting quality.

- Z axis adopts precision ball screw drive; linear guide rail guide, stable operation and fast response.

Fiber laser resonator

Fiber laser source is the latest generation of laser resonator, representing the trend of laser development, widely used in the processing of various plates and even non-ferrous metals

Unique advantages of fiber laser generator

- Electro-optical conversion efficiency reaching up to 32%;

- Extremely excellent pulse power/energy stability;

- Long service life, high precision, and service life of pumping source reaching over 100,000 hours;

- Higher speed and better effect;

- Beam quality optimized for applications;

- Air-cooling compact structure design;

- Low-cost compact solution with semi-conductor fiber as laser generation medium, eliminating needs for laser generation gas and achieving environmental-friendliness;

- Small volume, light weight and free of maintenance;

- Core parts employs vertically integrated production, provided with over 40% hot redundancy and subject high reflectivity test of over 90% power.

IPG Laser source

- Electro-optical conversion efficiency reaching up to 32%;

- Extremely excellent pulse power/energy stability;

- Long service life, high precision, and service life of pumping source reaching over 100,000 hours;

- Higher speed and better effect;

- Beam quality optimized for applications;

- Air-cooling compact structure design;

- Low-cost compact solution with semi-conductor fiber as laser generation medium, eliminating needs for laser generation gas and achieving environmental-friendliness;

- Small volume, light weight and free of maintenance;

- Core parts employs vertically integrated production, provided with over 40% hot redundancy and subject high reflectivity test of over 90% power.

MAX laser source

- The MAX fiber laser has high electrical-optical conversion efficiency, and the conversion efficiency is more than 30%. The medium power fiber laser uses water cooling, which can greatly save power consumption during operation, save operating costs, and achieve the highest production efficiency;

- The laser only needs electrical energy during operation, and does not need extra gas to generate laser, and has the lowest operation and maintenance cost;

- The fiber laser adopts semiconductor modular and redundant design. There is no optical lens in the resonant cavity, which does not require startup time. It has the advantages of no adjustment, maintenance, and high stability. It reduces the cost of accessories and maintenance time. This is a traditional laser. incomparable;

- The output wavelength of the fiber laser is 1.07 um, which is 1/10 of the CO2 wavelength. The output beam quality is good, the power density is high, which is conducive to the absorption of metal materials, and has excellent cutting ability, so as to minimize the processing cost;

- The optical transmission of the whole machine is through optical fiber transmission, and does not require complex light guide systems such as reflectors.

Gas and water system

- The gas path system of fiber laser cutting machine comprises two parts, one being cutting gases provided to cutting head which comprise compressed air, oxygen and nitrogen, and the other being auxiliary gas which is dry and clean compressed air;

- The high-pressure nitrogen passes through the high-pressure pipe and is controlled by the high-pressure solenoid valve to directly enter the cutting head. At the same time, it is equipped with a manually adjustable high-pressure relief valve. The nitrogen pressure can be adjusted when cutting different plate thicknesses to save nitrogen consumption

- The cutting section is not required high quality, high-pressure air can be used for cutting, and the pipeline is shared with high-pressure nitrogen, and the three-way ball valve is used for switching, which is convenient and fast, and can save the cost of cutting auxiliary gas

- The waterway system includes two parts: a part of the cooling water comes out of the chiller, enters the laser, cools the laser through the radiator inside the laser, and returns to the chiller. This part belongs to the low temperature part; Enter the QBH through the laser and return to the chiller.

Laser cutting head

Cutting head and follower

- The auto focus laser cutting head BM111, Raytools. The performance is stable and reliable, and the high cutting speed is achieved while ensuring the best cutting quality.

- The standard focal length lens can be used for cutting plates of different thicknesses, avoiding the trouble of changing different focusing lenses.

- One-key start, automatic calibration, non-contact capacitive sensor to ensure the stability of cutting follow-up gap. Even if the surface of the plate is not flat enough, it can achieve a good cutting effect.

- Through the sensor on the cutting head, it can automatically find the edge of the plate quickly, detect the position and angle of its vertex, and automatically adjust and correct the cutting program according to the measured actual position, saving operation time and reducing labor intensity.

- After the cutting is completed, the cutting nozzle is automatically cleaned to extend the service life of the cutting nozzle and improve the processing quality.

Product configuration

Scope of supply

| No. | Name | Brand | Q’ty |

| 1 | Main machine | YAWEI | 1 |

| 2 | 6000W Laser source | IPG YLS-6000-U-K/ Raycus RFL-C6000S/ Max MFSC-6000 | 1 |

| 3 | Laser cutting head | BS06K auto focus, Raytools Switzerland | 1 |

| 4 | Chiller | 同飞Tongfei, China | 1 |

| 5 | Dust remover(fan blower) | Yiyong, China | 1 |

| 6 | Stabilizer | Xishun,China/Lioa Viet Nam | 1 |

| 7 | Wireless hand wheel | standard | 1 |

| 8 | Auto lubrication | Standard | 1 |

| 9 | Partition: dust removal system | Standard | 1 |

Key component list

| No. | Configuration | Configure Content | Brand |

| 1 | CNC controller Beckhoff | WIN10 | Beckhoff,Germany (Screen:YAWEI) |

| CPU: Intel core I3 RAM: 4GB SSD: 64 GB Ethernet port: 2 USB port: 1 preposition, 4 postpositions | |||

| 2 | 传动系统组成Drive system composition | High precision linear ball guide rail | PMI,Taiwan |

| High precision helical rack | LINDEN SWEDEN, Sweden | ||

| High precision disk reducer | DESBOER, Japan | ||

| The servo motor and drive | Physis, China | ||

| Guide rail dust cover | China | ||

| 3 | Compositions of pneumatic system | Pressure reducing valve, check valve, throttle valve | SMC,Japan/ Airtac,China,etc |

| Cylinder, solenoid valve | |||

| Two-way valve | |||

| 4 | Compositions of electrical system | Contactor, air switch, etc. | SIEMENS,Germany/ SCHNEIDER,France |

| Optoelectronic switch | OMRON,Japan | ||

| Relay module | WEIDMULLER,Germany

| ||

| Terminal | WEIDMULLER/WAGO, Germany | ||

| Tank chain | China |

Installation requirement

The installation and operation of the HLE series fiber laser cutting machine is performed in accordance with the GB7247-87:Radiation safety of laser products equipment classification requirements and users guide and GB10320-88:Electrical safety of laser equipment and installation

Equipments needed before installation

| No. | Item | Parameters | Unit | ||

| 1 | Power Source | 380/50 | V/Hz | ||

| 2 | Required distribution capacity | 50 | kVA | ||

| 3 | Stability of power supply | ±10% | |||

| 4 | Computer | Win 7 – Win 10 | |||

| 5 | Oilless air compressor | Non-air cutting version | Flow ≥1.0 | m3/min | |

| Pressure ≥0.8 | MPa | ||||

| Oil content ≤0.002 | ppm | ||||

| Air cutting version (cutting thickness and quality deteriorate and the section is yellowish and gray with increased burrs) | Flow ≥1. 0 | m3/min | |||

| Pressure ≥1. 3 | MPa | ||||

| Oil content ≤0.002 | ppm | ||||

| 6 | Air storage tank | Non-air cutting version | Volume > 0.6 | m3 | |

| Pressure resistance > 1.0 | MPa | ||||

| Air cutting version | Volume > 1.0 | m3 | |||

| Pressure resistance > 1.3 | MPa | ||||

| 7 | Tertiary filter | Grade I: treatment capacity is 1.5 m3/min, degreasing accuracy is 3mg/m3 (3ppm) and dedusting accuracy is 3μm. | |||

| Grade II: the treatment capacity is 1.5 m3/min, degreasing accuracy 0.1mg/m3 (0.1ppm) and dedusting accuracy 1μm. | |||||

| Grade III: the treatment capacity is 1.5 m3/min, degreasing accuracy 0.01mg/m3 (0.01ppm) and dedusting accuracy 0.01μm. | |||||

| 8 | Oxygen for cutting carbon steel sheet | The purity is above 99.9% | |||

| 9 | Nitrogen for cutting stainless steel | The purity is above 99.99% | |||

| 11 | Water for chiller ( “Watsons” brand of distilled water is recommended.) | 50 | L | ||

| Conductivity 30-50 | μs | ||||

| 12 | Ground resistance | ≤4 | Ω | ||

| 13 | The installation environment temperature of laser generator | 5-40 | ℃ | ||

HLE Yawei series Laser Cutting machine

(0 customer reviews)Customers comment on the product

Related products

- The new generation design follows the HLE model, bringing a wide range of options to the high-end segment lasers.

- Beckhoff controller; driver, servo motor, Physic driver or option of famous brands.

- Solid mechanical structure, high production standards, system of moving parts from high-end brands.

- Alarm system, easy maintenance and operation.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- Single-table machine, without guards, effectively cuts thin metal sheets, suitable for materials ≤ 12mm thick. …

- Imported fiber laser source, long life, low maintenance cost, fuel-saving and environment-friendly.

- The machine structure is neat, saving warehouse space, convenient for all levels of work, districts and manipulation when operating.

- High-end accessories such as German brand IPG laser source, Raytools – Switzerland cutting head, rack, gears and gearboxes from Japan, Sweden.

- Equipping the whole machine with voltage stabilizer and automatic lubrication system

- Meets the precision standards of the sheet metal processing industry.

- Single desk

Metal sheet cutting, metal pipe not available

1.5kw / 2kw / 3kw / 4kw available

- A new generation of extremely fast fiber laser cutting machine matches the international level

- Cutting efficiency and precision of complex workpiece beyond imagination

- The bed and beam structure, control and transmission system, and laser processing technology are significantly improved

- With job list function, remote diagnosis service, health protection system, interconnection with the production management center

- Quality meets European standards, is rated as China’s No.1 laser cutting machine product.

- New styling with marked improvement in cutting performance.

- High performance, high speed, acceleration reaches 2.0 – 2.8G.

- Gate-shaped machine structure, parallel two-rail movement, moving beam made of monolithic aluminum alloy, conversion table allows double working productivity, working table height is always kept at a fixed level thanks to the mechanism. hydraulic lift.

- High-end accessories: IPG laser source, Precitec cutting head, Siemens controller, Schneider electrical components

- Super fast cutting speed for thin materials, stable cutting for medium and thick materials.

- The combination of laser angle cutting technology and advanced numerical control technology, accompanied by a humanized HMI interface and an upgraded professional laser cutting database.

- Automatically adjust air pressure, cutting power, cutting speed according to material thickness.

- Automatic calibration feature allows good cutting of warped sheets.

- Automatic cutting head cleaning feature.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

Model: LC26035XD

Brand: BRUCO

Laser Source: MAX 20000W

Controller: FSCUS 10000

Warranty: 24 months for laser source and machine

- Compact structure and small footprints

- The cutting area is open for easy loading and unloading, adapting to a variety of venues and use environments

- The dust removal port is close to the lower part of the cutting area,greatly improves the dust removal efficiency and ensures the long-term stable operation

- The plate welding frame is matched with the aluminum alloy beam to meet the requirements of high acceleration motion

- Separate electric control cabinet can adapt to the spatial arrangement of different venues

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.