No products in the cart.

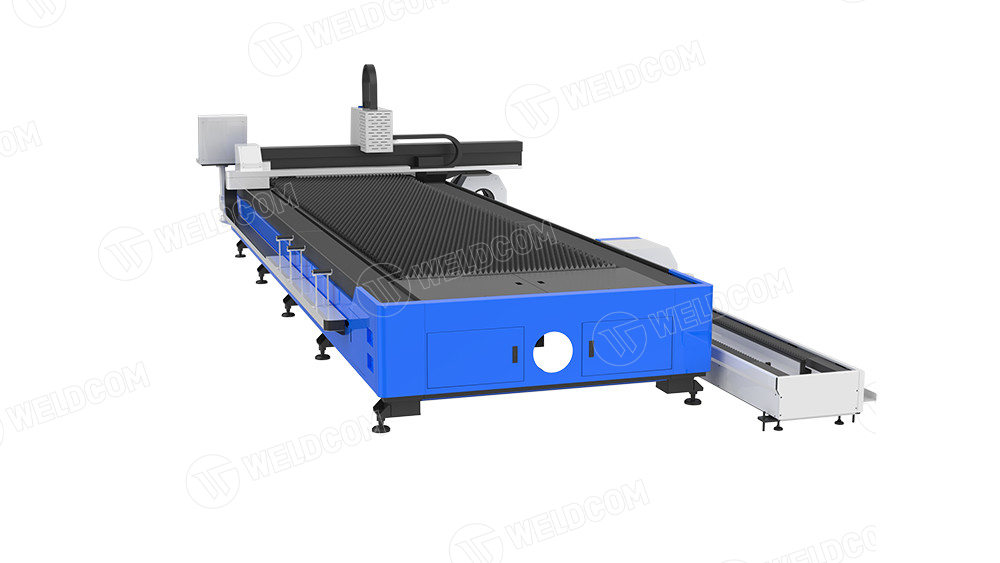

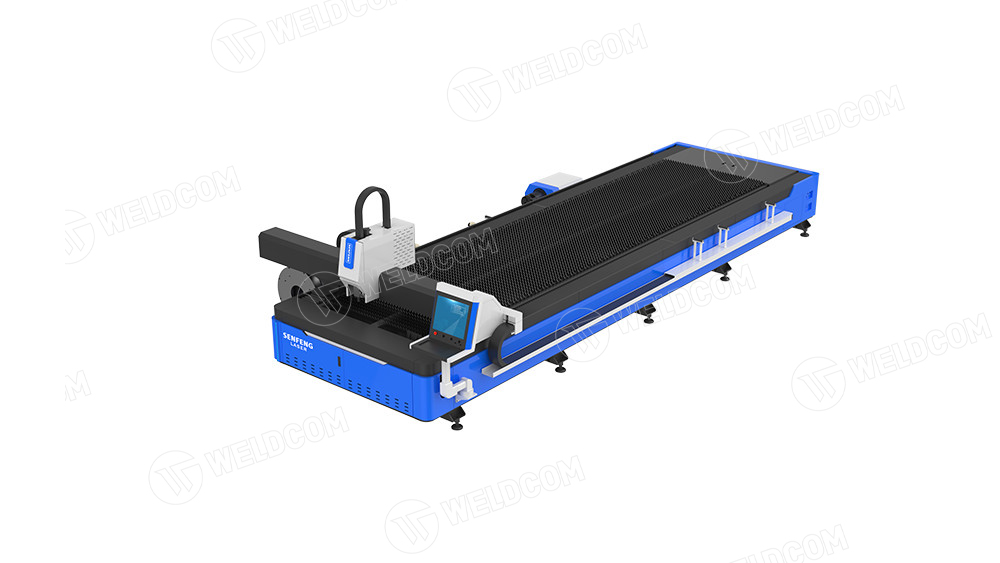

SENFENG SF6020M LASER FIBER SHEET CUTTING MACHINE

- (0 customer reviews)

- Write a product review

- Print this page

Thương hiệu:

Mã sản phẩm:

Mô tả sản phẩm:

- The SF6020M fiber laser cutting machine is rated to the top level in China, being the best choice of customers in the metalworking industry. The machine is used to cut mild steel up to 16mm.

- The frame has a honeycomb carbon structure, using a heat annealing treatment. Die-cast aluminum beam and whole machine bed are welded, with high strength and stability. The running speed of the machine can reach 80 m/min, which can process round pipes with a diameter of less than 200 mm and square pipes with a side length of less than 150 mm.

- Sheet cutting size: up to 6000 x 2000 mm.

- Round pipe size: 20 – 220 mm; Square 14 – 150 mm.

Senfeng SF6020M fiber laser cutting machine reaches the top level in China, is the best choice of customers in metal industry. The machine is used to cut mild steel up to 16mm.

Autofocus cutter – Raytools

Autofocus cutter – Raytools

- The cutting head from Switzerland is commonly used in the market.

Fully enclosed inner structure can avoid dust.

Automatic focus adjustment by servo motor is fast and accurate and improves chiseling.

The protective glass has a convenient alternative drawer installation.

Can be equipped with various types of QBH connected laser sources.

RAYCUS . laser source

It has the advantages of high electro-optical conversion efficiency (> 40%), good beam quality, high power density, wide modulation frequency, high reliability, long life and maintenance-free operation. . It can be widely used in welding, precision cutting, cladding and surface treatment, 3D printing and other fields.

Rack, gear, slider transmission system

High precision, long life, can provide rigorous support for helical gear quenching and helical gear grinding, so the load transmission structure is compact, can effectively reduce the torque transmission.

Workpiece chuck

The Senfeng SF6020M cutter has both front and rear chucks that are pneumatically clamped with a minimum tail length of 20mm. The chuck allows clamping φ20 ~ φ220 mm round pipe, combined with servo motor and synchronously driven reducer to ensure processing accuracy.

Water cooling system – Hanli

During the working process, the laser source and the laser cutting head are the two largest heat-generating and heat-resistant parts. If not cooled in time, these two parts will increase in temperature very quickly leading to the device being burned out quickly. Therefore, the company has used Hanli coolers for large cooling capacity, stable performance, no problems, clean water quality, good heat exchange efficiency with fiber lasers and secure link signals. laser protection.

Control software Tubepro

The tube cutting control software of the FSCUT3000 series is used in the ultra-high speed laser tube cutting machine. It has the functions of real-time offset compensation, automatic bar feeding, manual debugging, one main alignment pipe head, automatic centering, angle technology, weld detection, curve monitoring and core offset compensation. tube.

BCS 100 . torch height adjuster

The BCS100 torch height controller is a torch height device relative to the material surface. Besides normal control similar to other products, BCS100 also provides unique Ethernet communication interface (TCP/IP protocol) by connecting with CypCut laser cutting software for tracking and segmentation, cutting edge, chisel, etc. In addition, the torch height adjuster possesses many features such as:

- Sampling rate 1000 times/second.

Static measurement accuracy 0.001 mm.

Dynamic accuracy 0.05 mm

Servo control height from 0 to 10 mm.

Control speed up to 375 mm/s

Signal transmission cable length is 100 meters, strong anti-interference ability.

Support network communication, online upgrade, support touch screen alarm.

Support automatic edge and rounded edge detection.

Some pictures of Senfeng SF6020M fiber laser cutting machine

If you are interested, please leave your information in the quotation section to receive detailed advice and quotation from Weldcom for fiber laser cutting machine Senfeng SF6020M

Or contact hotline: 19009410 for more information.

SENFENG SF6020M LASER FIBER SHEET CUTTING MACHINE

(0 customer reviews)Khách hàng nhận xét về sản phẩm

Related products

- SF3015G single table fiber laser cutting machine without protective cover is a good choice of customers in the popular segment. Machine for Ability to cut steel, stainless steel, aluminum alloy and other steels;

- Machine frame is annealed and stress treated after welding, machine beam parts are manufactured by cast aluminum.

- The machine is applied in automobile industry, sheet metal industry, furniture industry, advertising industry, etc.

- Single-table machine, without guards, effectively cuts thin metal sheets, suitable for materials ≤ 12mm thick. …

- Imported fiber laser source, long life, low maintenance cost, fuel-saving and environment-friendly.

- The machine structure is neat, saving warehouse space, convenient for all levels of work, districts and manipulation when operating.

- High-end accessories such as German brand IPG laser source, Raytools – Switzerland cutting head, rack, gears and gearboxes from Japan, Sweden.

- Equipping the whole machine with voltage stabilizer and automatic lubrication system

- Meets the precision standards of the sheet metal processing industry.

- A new generation of extremely fast fiber laser cutting machine matches the international level

- Cutting efficiency and precision of complex workpiece beyond imagination

- The bed and beam structure, control and transmission system, and laser processing technology are significantly improved

- With job list function, remote diagnosis service, health protection system, interconnection with the production management center

- Single desk

Metal sheet cutting, metal pipe not available

1.5kw / 2kw / 3kw / 4kw available

Model: BLC3000

Ray 3.15 x10m (15Kg/m), 1 steam CNC + 1 CNC Plasma (on the same mine lifter), with Sigmanest Companion software, Huayuan HYCC-M3 CNC control system.

Model: BLC4000

Ray 4 x14m (15Kg/m), 1 mỏ CNC hơi+1 CNC plasma (trên cùng một bộ nâng hạ mỏ), kèm phần mềm Sigmanest Companion, hệ thống điều khiển CNC Huayuan HYCC-M3.

- Quick response to control, saving gas, electricity and cost

- Using bright surface cutting technology, fast cutting speed, small slope, low roughness

- Gantry double-drive high-rigidity bed structure, annealing and stress-relieving operation to sensure efficient and stable running

- Humanized operation interface and cutting parameter library are fully upgraded

- Quality meets European standards, is rated as China’s No.1 laser cutting machine product.

- New styling with marked improvement in cutting performance.

- High performance, high speed, acceleration reaches 2.0 – 2.8G.

- Gate-shaped machine structure, parallel two-rail movement, moving beam made of monolithic aluminum alloy, conversion table allows double working productivity, working table height is always kept at a fixed level thanks to the mechanism. hydraulic lift.

- High-end accessories: IPG laser source, Precitec cutting head, Siemens controller, Schneider electrical components

- Super fast cutting speed for thin materials, stable cutting for medium and thick materials.

- The combination of laser angle cutting technology and advanced numerical control technology, accompanied by a humanized HMI interface and an upgraded professional laser cutting database.

- Automatically adjust air pressure, cutting power, cutting speed according to material thickness.

- Automatic calibration feature allows good cutting of warped sheets.

- Automatic cutting head cleaning feature.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

- The design promotes efficiency, economy, reasonable and optimal machine structure.

- Gate structure with two parallel moving rails, two switching workbenches improves productivity, high speed with 2.1G acceleration.

- Fiber laser transmission, no mirror system, so the cost of operation and maintenance is very low, working reliably and stably.

- The chamber protects the main cutting table area, limiting smoke and dust.

- The sight glass is anti-laser and provides high safety for operators.

- Imported components, long life and stability: Beckhoff controller – Germany, IPG laser source, Raytools cutting head – Switzerland…

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.