SIGMANEST

Sigmanest Powerpack software is a solution package from SigmaTEK Systems – A leading global provider of advanced CAD/CAM software solutions that help professional manufacturers increase profits by optimizing material usage. , machine movement, manpower and data management.

Sigmanest Powerpack software

- Material: The software increases productivity and saves materials by 2-4% compared to conventional ones.

- Motion (Optimized CNC cutting machine movement): The cutting machine applies software for faster cutting, shortening production time by 20%.

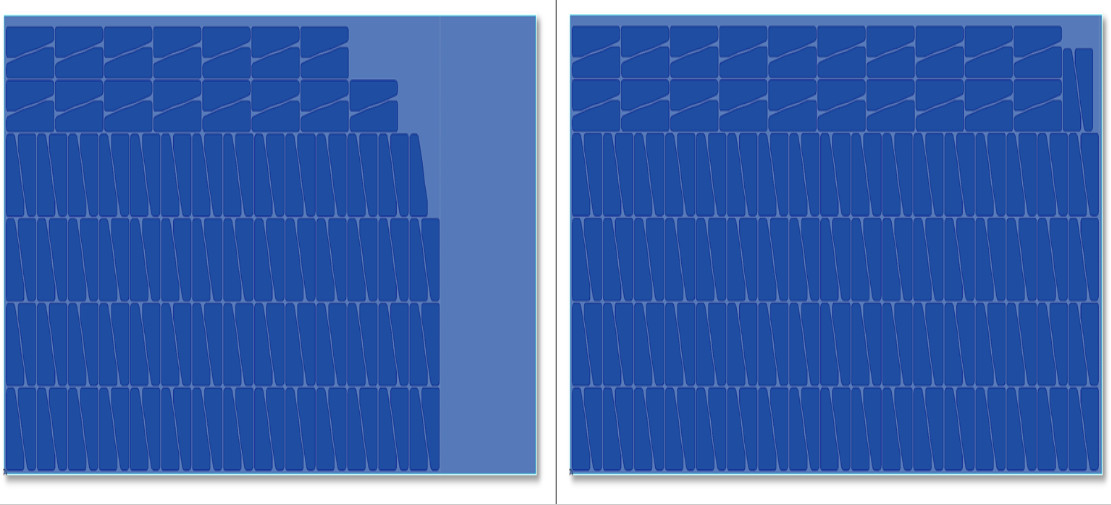

The software saves material 2-4% more than conventional

- Manpower: Reduce manpower, time on sorting, mixing, cutting on average 2 times faster.

- Manage: Sigmanest integrates data, detailed operating information of machines and areas.

- Machines: Create convenience and flexibility by operating multiple machines using only one software.

- Automatically convert from drawings to arrangement details.

- Select the appropriate corrugated board for optimal arrangement of multi-head cutters on a wide range of materials.

- Anti-stack Pump drag-and-drop properties for easy use.

- Features cut bridge (bridge), cut chain (chain), share road (common cut).

Common cut feature when using Sigmanest software

- Feature to avoid collision of torch and cutting product.

- Keep track of remaining cut sheet material and inventory.

- Automatically classify jobs by type, material thickness.

- Multiple sheets of material are displayed on the screen and can be manually moved over multiple sheets of material.

- iPierce primer hole sharing feature.

- Pre-piercing pre-piercing feature.

In Vietnam, Weldcom is the only owner authorized by Sigmateck to distribute and support Sigmanest. When becoming a partner of Sigmateck, Weldcom has distributed products to many large-scale enterprises such as Huy Thanh Mechanical and Metallurgical Company Limited, Thanh Tien commercial production company, Dai Dung steel structure corporation…

With a system of more than 1,300 agents and branches nationwide, Weldcom hopes to be a bridge to closely link Sigmanest products to Vietnamese businesses in the future.

Tiếng Việt

Tiếng Việt