- INVERTER IGBT

- Seperate wire feeder.

- Quick response for spot welding.

- Portable with light weight.

- Digital display for current and voltage.

- Concise and user-friendly pannel.

- Equipped with multiple welding functions

- Digital control mode and man-machine interaction for easy and convenient operation.

- Complete auto protection with 6 sets parameters protection to guarantee high reliability.

- Useful welding process management function to store 5 sets of most frequently used welding parameters.

- INVERTER IGBT

- Digital control technology enhances performance

- Automatic parameters saving

- Excellent performance with Pulse TIG, especially for thin material welding.

- Stable arc with less spatter and good shaping

- Remote control

- INVERTER IGBT

- Muti-function integrates argon welding, manual welding and cold welding.

- Easy arc striking, less spatter, stable current, and good shaping.

- HF is available for easy arc ignition.

- Widely used in carbon steel, stainless steel, alloy steel, heat-resistant steel, copper, titanium and titanium alloys etc.

- INVERTER IGBT

- Easy arc ignition with high frequency.

- Good arc stiffness and concentrated heat.

- Stable arc without spatter and good shaping.

- Suitable for welding materials such as steel, stainless steel, titanium, copper, nickel and their alloys.

- Applicable in vessel, bike, decoration, outdoor advertising, etc.

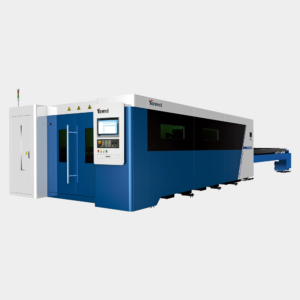

- The SF6020M fiber laser cutting machine is rated to the top level in China, being the best choice of customers in the metalworking industry. The machine is used to cut mild steel up to 16mm.

- The frame has a honeycomb carbon structure, using a heat annealing treatment. Die-cast aluminum beam and whole machine bed are welded, with high strength and stability. The running speed of the machine can reach 80 m/min, which can process round pipes with a diameter of less than 200 mm and square pipes with a side length of less than 150 mm.

- Sheet cutting size: up to 6000 x 2000 mm.

- Round pipe size: 20 – 220 mm; Square 14 – 150 mm.

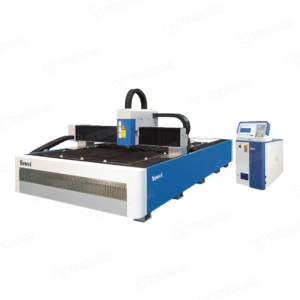

- SF3015G single table fiber laser cutting machine without protective cover is a good choice of customers in the popular segment. Machine for Ability to cut steel, stainless steel, aluminum alloy and other steels;

- Machine frame is annealed and stress treated after welding, machine beam parts are manufactured by cast aluminum.

- The machine is applied in automobile industry, sheet metal industry, furniture industry, advertising industry, etc.

- Đầu cặp vặn nhanh 10mm tiện dụng

- 2 cấp tốc độ với chức năng đảo chiều

- Đèn LED chiếu sáng

- Thiết kế nhỏ gọn với tay cầm mềm mại chống trượt

- Quick response to control, saving gas, electricity and cost

- Using bright surface cutting technology, fast cutting speed, small slope, low roughness

- Gantry double-drive high-rigidity bed structure, annealing and stress-relieving operation to sensure efficient and stable running

- Humanized operation interface and cutting parameter library are fully upgraded

- A new generation of extremely fast fiber laser cutting machine matches the international level

- Cutting efficiency and precision of complex workpiece beyond imagination

- The bed and beam structure, control and transmission system, and laser processing technology are significantly improved

- With job list function, remote diagnosis service, health protection system, interconnection with the production management center

- Compact structure and small footprints

- The cutting area is open for easy loading and unloading, adapting to a variety of venues and use environments

- The dust removal port is close to the lower part of the cutting area,greatly improves the dust removal efficiency and ensures the long-term stable operation

- The plate welding frame is matched with the aluminum alloy beam to meet the requirements of high acceleration motion

- Separate electric control cabinet can adapt to the spatial arrangement of different venues

– Perfect combination of production efficiency and performance

– High-speed cutting of thin plates, precise and perfect piercing of medium and thick plates

– Intelligent operation interface for equipment status monitoring and comprehensive upgrade of cutting expert parameter library

– Nano-level interpolation, independent CNC control technology, to ensure extremely fast response of each axis

The Hurco TM8i CNC slant-bed turning center is equipped with a small footprint, large work cube, ergonomic design, and an affordable price tag. The rigid one-piece machine base casting is designed to yield excellent static and dynamic performance in addition to outstanding dampening properties that inhibit thermal deformation and twisting, providing a more rigid turning center than competitive models in its class.

The Hurco VM CNC Vertical Machining Center offers powerful machining in a compact size, and best value on the market. The perfect combination of size and function. Large workspace with impressive X journey but does not occupy a large area of the factory.

317.900.000 ₫

Yousheng YS-425CNC-L automatic pipe cutting machine is a modern and advanced device for cutting pipes with high precision and efficiency.

Tiếng Việt

Tiếng Việt