Overview of VIETNAM WELDING ACCESSORIES MARKET – CHALLENGES AND OPPORTUNITIES

Entering the explosive era of e-commerce and logistics, importing goods is becoming more and more convenient, fast and cost-effective. Now, geographical distance is no longer an obstacle. Anyone can buy goods from abroad with very attractive shipping times and prices.

(Common welding accessories)

Not out of that development momentum, the welding – cutting accessories market in Vietnam is becoming more and more exciting with the participation of many intermediate suppliers. Products are more and more diverse in terms of types, brands, quality and prices. As a result, consumers can freely choose according to their individual needs. However, the absence of reputable units leading the market has made fake goods and counterfeit goods more and more rampant, seriously affecting the interests of consumers and genuine sellers.

Market chaos originates in the supply chain

Currently, most accessories in Vietnam are imported from China. This is the world’s giant factory, owning many large and small-scale accessory production units. However, only a few of them can make high-quality products that fully meet international standards. In addition, there are small, spontaneous processing workshops with the ability to mass-produce cheap, low-quality products with increasingly sophisticated and difficult-to-recognize packaging and appearance. This has always been a huge threat to genuine accessories.

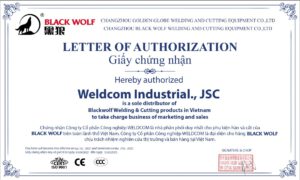

(The dealer must import fake goods at the same price as the real ones)

The problem becomes even more serious when in Vietnam, a large part of suppliers are still chasing short-term profits, choosing to sell fake goods, imitation goods, even selling fake goods at real prices. On the other hand, many buyers and sellers do not have enough knowledge and experience to distinguish the real from the fake. The above factors make it easier for cheap, low-quality products to mix and expand, making the overall picture of the domestic welding and cutting accessories market more chaotic than ever.

Direct and long-term consequences from the use of poor quality goods

Cheap products are made very poorly. Many details are omitted or simplified to minimize production costs. Mixed materials, not guaranteed. Therefore, their lifespan is often much shorter than the genuine product.

Weldcom has carried out many tests to compare the quality, service life and performance of genuine and cheap products floating in the market. The selected models are popular accessories such as electrodes, cutting tips, welding tips. The results show that the genuine electrode and cutting tip give a smoother, more beautiful cut. Alloy solder tip does not cause wire shaking, wire clogging and especially has a lifespan 3 to 6 times longer than normal tip. Meanwhile, poor quality products are usually only 1.5 to 2 times cheaper than genuine ones. Therefore, using fake goods, imitation goods, poor quality goods will certainly not be a reasonable and long-term cost-saving solution for businesses.

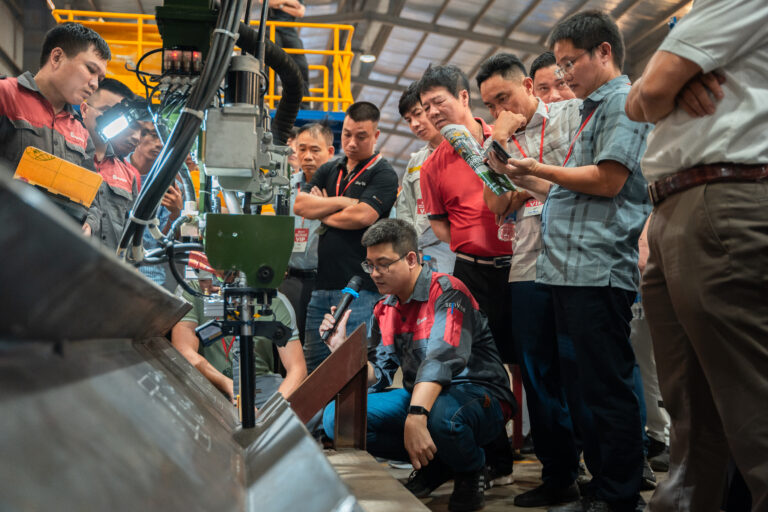

Efforts to bring genuine products to consumers

A recent survey has shown that the two top factors consumers care about when buying welding and cutting accessories are quality and price.

In the context of increasing customers’ awareness of using genuine products to ensure quality, suppliers need to seize opportunities and say no to fake, imitation and poor quality goods in order to be able to enhance its reputation and go far in this potential market.

Tiếng Việt

Tiếng Việt