WELDCOM TECHNOLOGY DAY 2023 – NETWORKING – UPDATING NEW TRENDS IN THE STEEL STRUCTURE INDUSTRY

The Weldcom Technology Exhibition 2023 took place on September 30, 2023, at the Weldcom Technology Center in Long Bien, Hanoi. It attracted participation from over 100 Vietnamese mechanical industry enterprises showcasing new products and advanced technologies.

The 2023 Technology Day event gathered nearly 200 representatives from over 100 Vietnamese mechanical enterprises. As an annual event organized by Weldcom, the exhibition focused on introducing the latest technological trends and fostering discussion and sharing among invitees and industry experts.

During the event’s opening, Mr. Ho Hong Thien, Chairman of Weldcom’s Board of Directors, expressed appreciation for the enthusiastic participation of the attendees. He highlighted the trend shifting from domestic production to exports, which has become a new direction for steel structure manufacturing enterprises in recent years. He emphasized that manufacturing technology is a crucial factor influencing this shifting trend and is characterized by rapid changes. Weldcom’s organization of the Technology Day not only updates customers on the latest solutions for the steel structure industry but also demonstrates their commitment to supporting customers by providing the best quality products and services.

Mr. Ho Hong Thien, Chairman of Weldcom’s Board of Directors, delivered the opening speech.

Under the theme ‘Technological Trends in Steel Structure Manufacturing,’ Weldcom presented customers with machines and technologies that have been enhanced in functionality and practical applications. Successively, Ms. Catherine, Director of International Business at ACME, and Mr. Nguyen Huu Hoan, Regional Sales Director (Zone 4) at Weldcom, delved deep into new solutions stemming from the trends in laser cutting machines for processing steel pipes and profiles. They also discussed the application of robots in the stiffening rib welding process for steel beams. Concrete data and specific examples provided customers with a comprehensive view of the solutions presented by Weldcom and ACME experts during the conference.

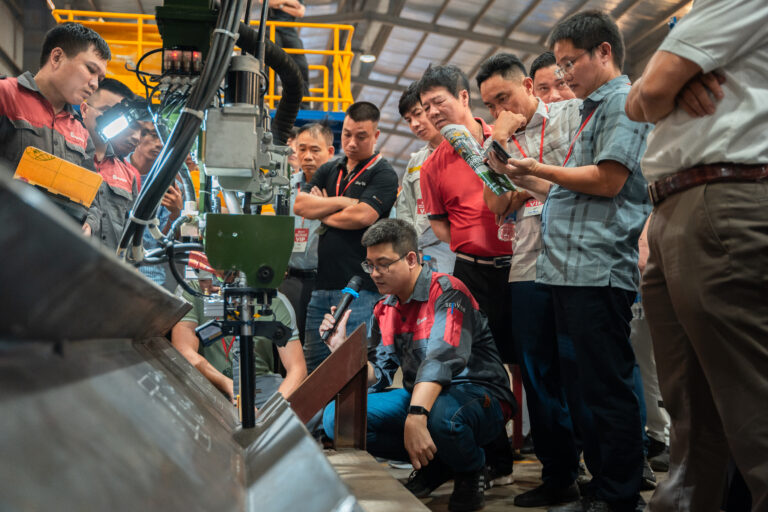

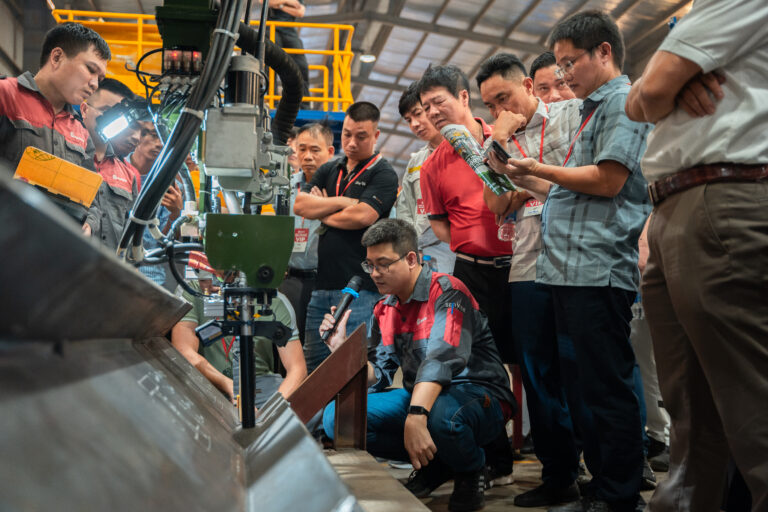

The highlight of the event garnered significant attention from the diverse attendees, particularly the live demonstration of the equipment at the Weldcom Technology Center. Weldcom unveiled the latest upgraded version of the Bruco BTMZ1800TP-A2 smart welding gate with numerous outstanding features. This version boasts the Tandem Saw 2 welding technology with 2 arc, achieving a welding efficiency of 500% and a production capacity of 300% compared to standard gates. It excels with materials up to 25mm thickness, reducing edge beveling and back gouging requirements. The intelligent control system with an intuitive interface and Vietnamese language support ensures user-friendly operations.

Additionally, the ACME LT-9035GKA laser pipe cutting machine deserves mention, capable of handling maximum round pipe diameters of 350mm, square tube diagonal cuts, and up to 495mm for steel profiles. It integrates superior cutting head systems and static cutting technology, enhancing cutting speeds by 20%, saving 60% energy, and increasing machine longevity by up to 50%. This solution is anticipated to become the leading choice for enhancing the manufacturing capabilities of steel structure enterprises.

The stiffening rib welding robot solution utilizes precise 3D cameras for accurate welding position identification, combined with dedicated software for simpler operation. The robot, coupled with intelligent software, accommodates complex welding shapes, optimizing solutions for the welding process in composite beam stiffening and box beams. Furthermore, Weldcom’s experts provided comprehensive explanations addressing efficiency, real operational capabilities, and economic considerations post-investment from the customer’s perspective, alongside product demonstrations and experiences during the event.

The unexpected highlight witnessed by numerous attending guests was the contract signing ceremony for the investment in the Senfeng SF12030R laser cutting machine between Weldcom and Hưởng Thanh Bình Construction LLC. A representative from Hưởng Thanh Bình Construction mentioned that the decision to invest in the laser cutting machine stemmed not only from thoroughly understanding the product but primarily from Weldcom’s capability in providing comprehensive solutions. This served as a foundation for the company to trust and decide to collaborate with Weldcom.

After the series of activities including the tour of the technology center and the display of advanced modern equipment, Weldcom organized a gala dinner for the esteemed enterprises participating in the ‘Technology Day.’ The dinner took place at the Long Bien Palace Event Center in Phuc Dong, Long Bien, Hanoi. At the event, Mr. Le Duy Xuan, Chairman of the Southern Steel Structure Association, shared high praise for Weldcom’s solutions, acknowledging their proactive approach to aligning with the industry’s upcoming manufacturing trends. He expressed deep appreciation for Weldcom’s mission and urged the company not only to consistently bridge the technology gap between Vietnam and the world but also to narrow the technology disparity between Vietnamese steel structure manufacturing enterprises and developed countries.

The 2023 Technology Day event left a lasting positive impression on visitors and also opened up opportunities for strong collaborations between Weldcom and businesses in the industry. Technology is ever-evolving, and Weldcom takes pride in being at the forefront, consistently delivering the latest and most advanced solutions and technologies to the mechanical businesses in Vietnam