- Direct drive spindle, high rigidity design

- BBt-40 spindle taper type, support double contact coupler

- High precision and excellent cutting ability

- Popular model, suitable for many types of production

- High performance value

- Mortar: 42 CrMo

- Main engine: Siemens Beide

- Electrical parts: Schneider/Siemens

- Hydraulic valve: Taifeng

- Hydraulic pump: Sunny/Hytek

- Gasket: NOK/Valqua

- Helix screw: ABBA/Hiwin

- The ZJKH planer machine features a frame structure design for its base and beam.

- The worktable is made of 60mm Q345 alloy steel while the frame is made of Q235 steel plate, providing good overall stiffness and durability.

- The machine’s worktable is stress-relieved to eliminate residual stress and reduce equipment deformation.

- The ZJKH groove-making machine uses four cutting blades to process “V” grooves, distributing the cutting load evenly and minimizing workpiece deformation.

- Additionally, the machine is equipped with 16 hydraulic clamp positions for better workpiece positioning

- The equipment is designed with frame structure, high strength bolt connection, good overall rigidity and small deformation.

- The outstanding advantages of the machine are heavy load, high speed and high efficiency.

- The machine is made of carbon tool steel and the hardness is above HRC55 after quenching, so the wear of the table is very small, helping to prolong the life of the device.

- Using 5.6KW high-speed, high-power servo motor. The machine is equipped with 4 cutting tools at the same time. The maximum cutting depth is 1mm, 3 times the efficiency of traditional equipment.

- The movable column design and automatic table change feature, can improve the production efficiency.

- ARM-type tool changer, tool change time only 0.9s

- Using BT-30 spindle, hard tapping up to 6,000rpm

- Suitable for small parts and magnesium alloy machining such as 3C . industry

- Truss structure design with high rigidity, high speed and high precision

- Lubricate the spindle with oil mist, which reduces heat and prolongs life

- Spindle speed up to 20,000rpm

- Excellent surface treatment accuracy

- Suitable for precision machining industries such as tools, tooling

- Excellent surface treatment accuracy

- Includes frame, servo system, laser source, laser cutting head, air system and water system for cooling, vacuuming and ventilation with workpiece catcher, table, punching plate, beam, pneumatic, lubrication and clamping system. .

- CNC servo punching: Frame structure, solid structure, high rigidity, servo-controlled punching force 294kN, punching frequency up to 700 cpm

- High efficiency, 2000cpm punching speed, energy saving and environmental protection, low noise and energy consumption.

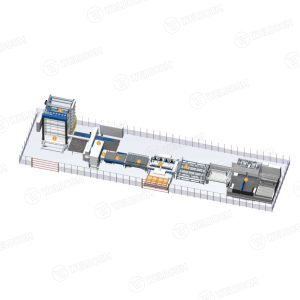

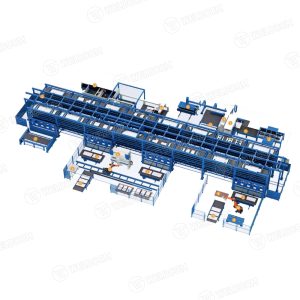

The automatic laser cutting line provided by Yawei can be used as a smart sheet metal factory device to communicate and share data with the ERP/MES production management center during processing. according to the production plan.

- Automatically complete loading, cutting and unloading of billets

- Perform batch and continuous processing of single sized billets

The punching unit of the punching machine has the functions of automatic billet feeding, punching and automatic loading and unloading and stacking. Feeding and unloading devices are located on both sides of the machine, which has strong scalability and high efficiency.

- Billet trolley

- Barrel feeding device

- CNC punching machine

- Billet unloading device

- Product lifting and unloading equipment

The plate face punching unit (FMC) has the functions of automatic feeding, punching and automatic loading and unloading and stacking.

The 3-in-1 CNC punching line combines automatic billet loading and unloading, integrating the advantages of punching and laser cutting processing.

The purpose of this processing system is to increase flexibility and automate the production of large flat sheet metal parts such as elevator doors and vehicle walls. The whole system includes: the raw material is selected by the automatic bar feeding system and transferred to the CNC punching machine to complete the punching process.

The long and short sides of the plate are bent using two gantry bending robots and two CNC bending machines. After the short edges are folded, they are transferred to the welding line to complete the rebar resistance welding, servo arc welding at the overlapping edges of the reinforcement ribs and bottom plate. The robot spot welds the overlapping edges of the bottom plate and stacks them on wooden pallets.

AMS.HSP sheet metal punching, cutting and bending combination line, integrated punching unit and cutting unit, bending unit to perform the entire process of punching, cutting, bending and folding automatically

Sheet metal automatic processing production line is a compact and flexible production line that integrates three-dimensional warehouse, CNC punching and cutting unit, pallet divider, turning device and needle folding unit.

CNC plate type, can automatically punch flat holes. The entire production line has large production capacity and small scale, and can realize fully automated material handling and high flexibility without manual intervention.

Comprehensive sheet metal processing (FMS) Dâysuitable for specific requirements and processes, coordinating the operations of each sheet metal production unit and automatically managing logistics. This system integrates various tools and high-performance sheet metal processing machines with the application of Yawei’s robot technology and data processing technology. Due to the variety of combinations of machines and equipment, this system can be widely used in automatic processing of various metal sheets.

Tiếng Việt

Tiếng Việt