No products in the cart.

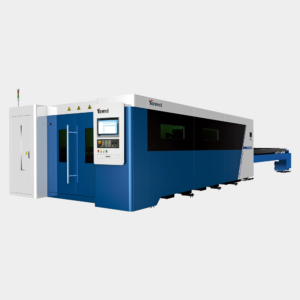

Tongtai EZ Series CNC Hole Milling Machine

- (0 customer reviews)

- Write a product review

- Print this page

Mã sản phẩm:

Mô tả sản phẩm:

- Tool change speed, tool change time T-T: 1-2s

- Servo motor-driven tool change system/ enables quick tool change

- Direct drive spindle motor, allowing quick acceleration/deceleration, hard tap up to 6,000rpm

- No-load travel speed up to 60m/min, acceleration up to 1.2G

- Maximum spindle speed reaches 24,000rpm

Tongtai EZ5 milling machine is the optimal choice for businesses that process parts, jigs, molds from aluminum and plastic that require precision, high surface gloss, uniform product quality and system products. holes that require quick and continuous tool change.

The machine is designed and simulated by the latest and most advanced finite element analysis (FAE) software. The platform is designed to be wider than that of the same configuration machines. The alignment of the stable base body helps to increase rigidity and reduce vibrations when running at high speed, contributing to improving accuracy, making the machined surface even more smooth. The whole machine is painted with electrostatic powder, with high adhesion and good scratch resistance.

Researched, developed and manufactured by Tongtai, Taiwan’s No. 1 brand of precision machining machines with quality that has been confirmed worldwide, every detail and part of the EZ5 milling machine is calculated infinitely. The same meticulous, careful to ensure the smooth operation of the machine, increase the accuracy of the product as well as the durability and stability of the machine during a long working time.

The case glass door part meets EN12417 standard and is CE licensed. 200 times more impact resistant than ordinary glass, ensuring operator safety.

The machine is controlled by MITSUMISHI M80 controller, Direct drive spindle, spindle speed 12000 rpm, with option up to 20,000 rpm or 24,000 rpm.

Longer shaft neck can meet the processing of complex parts, Special design isolates heat source from motor to ensure no thermal expansion to prolong spindle life. Due to the direct drive mechanism without loss of torque, noise and clearance, the machine can tap at speeds up to 6000 rpm and incorporates a spindle cooling system for continuous work for a long time. but still exactly stable.

The travel of the X/Y/Z axes reaches 510/400/300 mm, equivalent to the ability to process workpieces with a maximum length of 500mm in one attachment.

The idle speed of the axes reaches 60mm/min acceleration up to 1.2G, which helps to reduce the idling travel time.

Stronger, faster BBT30 dual contact clamp.

The tool station is controlled by servo motor, fast tool selection speed, T-T 1.2s high-speed automatic tool changer and sun-disc design, ensuring fast tool change speed and low cost, easy repair and maintenance.

The tool store can hold 16 tools, increasing flexibility when processing complex products that require many different tools, with the option of up to 21 tools.

Automatic lubrication system to all worm bearings, guide sliders to ensure smooth operation of parts, limiting wear and heat generation

With outstanding advantages and attractive policies, the EZ5 milling machine is currently the first choice of FDI enterprises and Vietnamese enterprises in the detail processing industry that have been and have the goal of entering the supply chain. Global.

In addition, with Weldcom’s service and customer care policy, customers will be supported by us:

- Available to support directly within 24-48 hours, after receiving the request from the customer.

- Live support on phone, online 24/7

- A team of long-term, skilled, experienced engineers, well-trained, and regularly improved in skills, in line with the actual requirements of customers and the trend of the times.

- With unexpected and difficult problems, customers will receive direct support from the company’s experts

- Parts warehouses are always available at representative offices and branches in Vietnam, so the warranty, maintenance and replacement of components are always timely and timely.

- 24 months warranty for software, 12 months for hardware, and lifetime product support

- Support customers to visit factories that are using Tongtai products for reference as well as exchange of experiences.

- There is always a preferential price policy for all customers

For more information or to receive a quote, please contact the hotline 19009410 or visit the website weldcom.vn.

Tongtai EZ Series CNC Hole Milling Machine

(0 customer reviews)Khách hàng nhận xét về sản phẩm

Related products

- Direct drive spindle, high rigidity design

- BBt-40 spindle taper type, support double contact coupler

- High precision and excellent cutting ability

- Popular model, suitable for many types of production

- High performance value

The Hurco VM CNC Vertical Machining Center offers powerful machining in a compact size, and best value on the market. The perfect combination of size and function. Large workspace with impressive X journey but does not occupy a large area of the factory.

- Direct drive spindle

- Machine design with sturdy structure

- Guide rail and ball screw drive system for high precision, 3-axis no-load travel speed up to 48m/min

- Improved cutting performance, stable processing performance

- Support custom design

- Suitable for the automotive industry

- The movable column design and automatic table change feature, can improve the production efficiency.

- ARM-type tool changer, tool change time only 0.9s

- Using BT-30 spindle, hard tapping up to 6,000rpm

- Suitable for small parts and magnesium alloy machining such as 3C . industry

- Workpieces up to 380 mm / H220 mm

- Equipped with CAM table, which enables high precision and strong rigidity

- 5-axis machining can complete complex processes in one go

- Performance value at a great cost

- Truss structure design with high rigidity, high speed and high precision

- Lubricate the spindle with oil mist, which reduces heat and prolongs life

- Spindle speed up to 20,000rpm

- Excellent surface treatment accuracy

- Suitable for precision machining industries such as tools, tooling

- Excellent surface treatment accuracy

- High rigidity structural design

- Lubricate the spindle with oil mist, which reduces heat and increases service life.

- Equipped with high-speed, high-precision control functions

- BBT-40 . dual contact tool change system

- Suitable for tool processing industry

- Fast tool change speed

- Tool change time T-T: VTX 5A/7A: T-T = 0.8s VTX 5/7: T-T – 1.2s

- High rigidity guide rail system

- Direct drive spindle motor, allowing quick acceleration/deceleration, hard tap up to 6000rpm

- Spindle diameter up to 50mm, increase rigidity when tar

Khối lượng:> 100 Kg

VIEWED PRODUCTS

- Compact design, flexible, easy to operate and highly efficient

- The machine has 2 operating modes Auto and Manual, using PLC convenient for workers to operate, with anti-clogging sensor.

- There are 02 high-capacity vacuuming silos, each silo has 9 dust filters, ensuring maximum dust collection during work (without affecting the environment).

- The machine uses Q034 turbine with high cleaning efficiency, low noise

Khối lượng:> 100 Kg

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets MZ1000 Jasic.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

- ZJKH machine base and beam are designed with frame structure. The working table is made of 60mm Q345 alloy steel. The frame is made of Q235 steel plate. The machine has good overall rigidity and durability.

- The table is annealed to eliminate residual stress and reduce equipment deformation.

- ZJKH grooving machine uses four cutters to process “V” grooves, so the cutting amount is evenly distributed and the workpiece deformation is minimized.

- The machine is equipped with 16 hydraulic clamp positions to help clamp the product positioning better.

- Workpieces up to 380 mm / H220 mm

- Equipped with CAM table, which enables high precision and strong rigidity

- 5-axis machining can complete complex processes in one go

- Performance value at a great cost

- The equipment is designed with frame structure, high strength bolt connection, good overall rigidity and small deformation.

- The outstanding advantages of the machine are heavy load, high speed and high efficiency.

- The machine is made of carbon tool steel and the hardness is above HRC55 after quenching, so the wear of the table is very small, helping to prolong the life of the device.

- Using 5.6KW high-speed, high-power servo motor. The machine is equipped with 4 cutting tools at the same time. The maximum cutting depth is 1mm, 3 times the efficiency of traditional equipment.

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Flux recovery system: 02 sets

- Welding source: 4 sets Megmeet Artsen CM500R

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

- Direct drive spindle, high rigidity design

- BBt-40 spindle taper type, support double contact coupler

- High precision and excellent cutting ability

- Popular model, suitable for many types of production

- High performance value

– Perfect combination of production efficiency and performance

– High-speed cutting of thin plates, precise and perfect piercing of medium and thick plates

– Intelligent operation interface for equipment status monitoring and comprehensive upgrade of cutting expert parameter library

– Nano-level interpolation, independent CNC control technology, to ensure extremely fast response of each axis

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.