GENERAL INTRODUCTION

- SMART GANTRY WELDING MACHINE DH1500TA3 integrates the most advanced TRIPLE welding technology, enhancing welding productivity to an outstanding level in the steel beam welding process.

- The machine is equipped with an automatic seam-tracking sensor system for each welding torch. This prevents positional deviations during welding, especially in cases of thermal distortion of the beam, uneven flange or web, or plate misalignment

MAIN PART

- Welding source: 02 set ASAW1250-AC/DC and 01 set ASAW1600 II

- Control system: 1 control cabinet, 1 control handle

OUTSTANDING FEATURES

- The machine offers flexibility in production by integrating 3 welding heads on a single machine body: Triple welding mode, Tandem welding, and single-wire welding.

- Well-suited for welding plates with a thickness of 20mm and above, capable of welding thick plates up to 25mm without the need for edge beveling, and welding non-beveled corners with a thickness of up to 25mm.

- A 100% duty cycle allows the machine to operate in demanding industrial environments.

- The touchscreen control panel, featuring a Vietnamese interface, and pre-installed welding DATA sets, facilitates easy training of machine operators, optimizing labor costs.

DH1500-S3A Version

- Using 3-wire 3 independent arc welding technology.

- In S3 welding mode, the ASAW1600 II source is responsible for creating penetrations with a welding current of 400-1600A DC, all of which are completed by the ASAW1600 II. In addition, with the advantage of reasonable price and the quality of Weldcom welding machine has been proven in the Vietnamese market.

- The DH1500-S3A integrates a laser sensor and a servo motor for weld line detection, enabling the welding machine to operate at high speed with stable and beautiful welds. Thanks to the use of a laser probe, multi-layer welding becomes easy and precise.

TECHNICAL DATA

| No | MODEL | Unit | Parameters |

| 1 | Beam width | mm | 300-1500 |

| 2 | Beam height | mm | 300-1500 |

| 3 | Beam length | mm | 4000 – 12000 |

| 4 | Crane rail length | mm | 16000 |

| 5 | Crane travel speed (frequency converter) | mm/ min | 100 – 3000 |

| 6 | Welding powder container | kg | 2*50 |

| 7 | Crane rail amplitude | mm | P24 |

| 8 | Welding travel speed | mm/min | 250 – 1000 |

| 9 | Air pressure | Mpa | 0.4 – 0.8 |

| 10 | Crane width | mm | 4710 |

| 11 | Crane height | mm | 4240 |

| 12 | Crane length | mm | 2655 |

| 13 | Servo motor for lifting and lowering the torch | w | 2*1.5 |

| 14 | Servo motor for moving the torch left and right | w | 2*750 |

| 15 | Welding powder suction motor | w | 2*3000 |

| 16 | Automatic welding powder discharge unit | 2*2 | |

| 17 | Welding position | 1F | |

| 18 | Wireless torch remote control | 2 | |

| 19 | Laser welding path detection sensor | 4 | |

| 20 | Power supply | V/Hz | 3 phase 380V±10%.50/60Hz |

| 21 | Welding wire diameter | mm | ø4.0- ø4.8 |

| 22 | Main machine power | kw | 6.6 |

| 23 | Load: 6-4.0 wire spools, weight: 125kg | kg | 2250 |

| 24 | Power | kw | 415 |

SMART GANTRY WELDING MACHINE DH-1500TA3

(0 customer reviews)Customers comment on the product

Related products

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets MZ1000 Jasic.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

The SMART HORIZONTAL WELDING MACHINE HN0630-S2 is the unique machine on the market that can weld multiple types of beams, including straight beams and specially shaped profiles such as A-shaped and K-shaped beams.

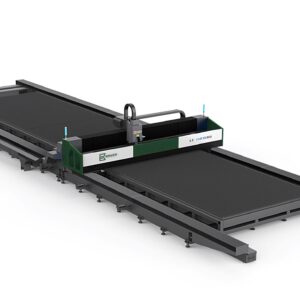

Model: LC26035XD

Brand: BRUCO

Laser Source: MAX 20000W

Controller: FSCUS 10000

Warranty: 24 months for laser source and machine

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

- Integrating 3 functions of attaching, welding and straightening on the same body system, is a solution to flexibly meet the needs of customers, helping to increase productivity, optimize space and cost

- The body is sturdy and stable

- Using Tandem MIG 2-wire technology under the drug layer for high speed and weld quality

- The welding source used for the machine is a welding source for robots with many advantages such as a wide, stable and durable input voltage range. The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and ensuring the quality of the weld.

Input voltage (V):3 pha 380 VAC

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.