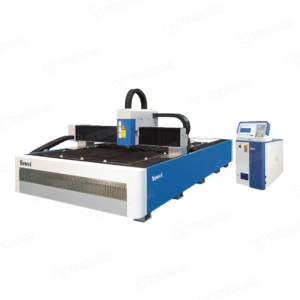

Metal Sheet Laser Cutting Machine SF3015G series

- (0 customer reviews)

- Write a product review

- Print this page

Trademark:

Product code:

Product description:

- Single desk

Metal sheet cutting, metal pipe not available

1.5kw / 2kw / 3kw / 4kw available

Advantages of Laser cutting machine SF3015G

High precision welding bed

- Fully automatic bed and cover production line, high product finishing speed

- Handle different working size, the size can be up to 6000mm*1500mm

Automatic oil filling

- Keep a fresh supply of oil

- Simple and flexible, avoid cutting oil

- Dual driver, dual rack, high speed

Cost optimization

- Less waste of raw materials

- Reasonable price

Pipe welding bed

- Welded box steel bed, tempered under high temperature, reduce internal pressure and deformation, its rigidity is strong, structural stability is high, enough to meet the use

The bed is 100mm lower than the old G, and the height of the bed is reduced to facilitate loading and unloading at the front and side.

The outer sheet metal is made of thick sheet metal, cut by our laser cutting machine and processed by bending machine

Under the premise of continuous dynamic performance, we optimize the structure, perfectly integrate the desk and bed, and directly place the blade on the bed to avoid shaking

The new G has eliminated the roller and simplified assembly, significantly shortening the production and assembly cycles and producing the equipment in the shortest possible time.

Cast aluminum beams

Aerospace standard cast aluminum beam, high precision, good strength, light weight, corrosion resistance, oxidation resistance, low density, and greatly increase the processing speed.

High precision rack and pinion

Double rack, dual driver, rack, guide and motor drive all use international top brand and use laser interferometer to check to ensure cutting accuracy; use the milling cutter to process the ruler more than 5 times to ensure the accuracy of the ruler, between the guide rail and the ruler

An adjustment block is installed to adjust the precision.

New and unique design

Unique laser head cover appearance, useful for red light observation and cooling, dust cleaning, avoid long time high temperature and damage to internal devices

Application of Fiber Laser cutting machine SF3015G

- SF3015G Laser Cutting Machine is used for cutting mild steel, stainless steel, aluminum alloy, brass and other steel.

Widely applied in automobile industry, sheet metal industry, furniture industry, advertising industry.

| Model | SF3015G/SF4015G/SF4020G/SF6015G/SF6020G metal laser cutting machine |

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

Metal Sheet Laser Cutting Machine SF3015G series

(0 customer reviews)Customers comment on the product

Related products

- SF3015G single table fiber laser cutting machine without protective cover is a good choice of customers in the popular segment. Machine for Ability to cut steel, stainless steel, aluminum alloy and other steels;

- Machine frame is annealed and stress treated after welding, machine beam parts are manufactured by cast aluminum.

- The machine is applied in automobile industry, sheet metal industry, furniture industry, advertising industry, etc.

- Compact structure and small footprints

- The cutting area is open for easy loading and unloading, adapting to a variety of venues and use environments

- The dust removal port is close to the lower part of the cutting area,greatly improves the dust removal efficiency and ensures the long-term stable operation

- The plate welding frame is matched with the aluminum alloy beam to meet the requirements of high acceleration motion

- Separate electric control cabinet can adapt to the spatial arrangement of different venues

- The new generation design follows the HLE model, bringing a wide range of options to the high-end segment lasers.

- Beckhoff controller; driver, servo motor, Physic driver or option of famous brands.

- Solid mechanical structure, high production standards, system of moving parts from high-end brands.

- Alarm system, easy maintenance and operation.

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

Model: BLC3000

Ray 3.15 x10m (15Kg/m), 1 steam CNC + 1 CNC Plasma (on the same mine lifter), with Sigmanest Companion software, Huayuan HYCC-M3 CNC control system.

Model: BLC4000

Ray 4 x14m (15Kg/m), 1 mỏ CNC hơi+1 CNC plasma (trên cùng một bộ nâng hạ mỏ), kèm phần mềm Sigmanest Companion, hệ thống điều khiển CNC Huayuan HYCC-M3.

- The design promotes efficiency, economy, reasonable and optimal machine structure.

- Gate structure with two parallel moving rails, two switching workbenches improves productivity, high speed with 2.1G acceleration.

- Fiber laser transmission, no mirror system, so the cost of operation and maintenance is very low, working reliably and stably.

- The chamber protects the main cutting table area, limiting smoke and dust.

- The sight glass is anti-laser and provides high safety for operators.

- Imported components, long life and stability: Beckhoff controller – Germany, IPG laser source, Raytools cutting head – Switzerland…

- Combined with the world’s number one Sigmanest nesting software for optimal cutting, efficient material management.

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.