THROUGH-TYPE GANTRY WELDING PLATFORM – CH14TD

- (0 customer reviews)

- Write a product review

- Print this page

GENERAL INTRODUCTION

The only machine in Vietnam developed by Bruco specificallyfor welding steel pipes with a diameter of up to 14m. It ensures high-quality welds, and productivity, minimizes intermediate steps, and is primarily applied in the national wind power industry

MAIN PART

- Main Machine: The welding gate with a flexible lifting and lowering mechanism allows easy adjustment of the diameter of the workpiece from 4000mm to 14000mm.

- The integrated welding head includes an automatic lifting and lowering system with a touch sensor.

- The automatic exhaust and fume recovery system helps prevent welding fume loss due to scattering.

- Control System: The intelligent control system can store various welding programs.

- It utilizes the control unit and user interface screen from KEYENCE, supporting both English and Vietnamese languages.

- Welding Power Source: The Tandem welding power source of a leading 1250A DC welding source and a trailing AC/DC 1000A welding source

OUTSTANDING FEATURES

- Integrated adaptive welding head adjustment system optimizes technology to ensure welding compatibility with various pipe sizes.

- Applies Tandem welding technology under the flux layer for fast welding speed and high-quality welds. The welding power source is specifically designed for Tandem welding, offering advantages such as a wide input voltage range, stability, and durability.

- Comes pre-installed with welding DATA sets, providing maximum support during operation, easy training for operators, and optimizing labor costs.

- Integrated Ethernet IP connection to link with SCADA or MES systems. Machine data will be sent to the server for comprehensive reporting by shift/day/month/quarter, evaluating the machine’s performance and workforce efficiency

TECHNICAL DATA

| No | MODEL | Unit | Parameters |

| 1 | Power supply | V/Hz | 3 phase, 380-400V, 50Hz |

| 2 | Rail | P43 | |

| 3 | Distance between 2 rail | m | 15 |

| 4 | Working floor | m2 | >28 |

| 5 | Motor for moving the gate & lifting & lowering the product | Variable frequency control | |

| 6 | Working height | m | 4 – 16 |

| 7 | Travel speed on the beam | m/ phút | 0.4 – 1.2 |

| 8 | Working floor lifting speed | m/ phút | 0.4 – 1.0 |

| 9 | Diameter of the product that can be welded | mm | 4000 – 14000 |

| 10 | Welding torch cluster | TANDEN SAW welding torch welding 2 wires with diameters (3.2mm/4.0mm/4.8mm) | |

| 11 | Welding powder discharge and recovery mechanism | Automatic (Motor power for recovering powder is 3kw, welding powder box is 50kg) | |

| 12 | Welding position detection mechanism | Contact mechanism (mechanical detection), self-adjusting position distance: 200mm. The mechanism consists of X, Y axes | |

| 13 | Weatherproof canopy | set | Yes |

| 14 | Maintenance and operation ladder | mm | 2 ladders |

| 15 | Control cabinet | kw | KEYENCE/MITSUBISHI |

| 16 | Gate travel distance | Fixed/movable | |

| 17 | Automatic welding powder suction unit | 1 | |

| 18 | Welding wire diameter | 2.4 – 4.8 | |

| 19 | Main machine power | ≥ 28,6 |

THROUGH-TYPE GANTRY WELDING PLATFORM – CH14TD

(0 customer reviews)Customers comment on the product

Related products

- Integrating 3 functions of attaching, welding and straightening on the same body system, is a solution to flexibly meet the needs of customers, helping to increase productivity, optimize space and cost

- The body is sturdy and stable

- Using Tandem MIG 2-wire technology under the drug layer for high speed and weld quality

- The welding source used for the machine is a welding source for robots with many advantages such as a wide, stable and durable input voltage range. The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and ensuring the quality of the weld.

- Laser sensor and Servo motor ensure high-quality weld seams.

- Smart welding torch assembly – supports 2F, 1F, and 1G positions, compatible with various beam types.

- Laser seam tracking with automatic flux feeding and recovery system.

- Optimized investment cost.

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

The SMART HORIZONTAL WELDING MACHINE HN0630-S2 is the unique machine on the market that can weld multiple types of beams, including straight beams and specially shaped profiles such as A-shaped and K-shaped beams.

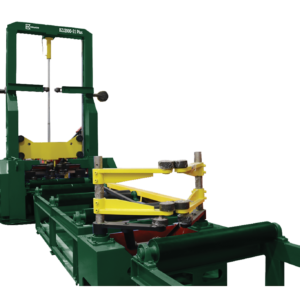

- BZJ2000-S1 Plus has a smart welding controller with interactive touch screen which is capable to program, manage information, store

data, connect Ethernet and report errors… - BZJ2000-S1 is preinstalled a set of welding / assembling parameters data. Thus, the operation process is more convenient and limits

errors when installing by operators. - BZJ2000-S1 has a monitoring user funtion to help evaluate performance.

- Centering pulling rod system includes 4 rollers (press flange) and 8 rollers (press web), moves by screw and slider to get high accuracy.

- Guide roller of compression cylinder is designed large size, strong, stable and easy to adjust.

- Welding torch is located at the optimal position, as a result, the assembly point is very accurate.

- Torch clamping device is designed strong and flexible ensure that the assembly point is always in the right position.

- The main motor locates under the machine body to save space and keep safely when operating.

- Hydraulic system is compact with only 160L oil tank.

- 30% higher productivity compared to normal machines

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.