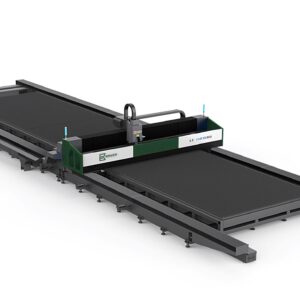

SMART GANTRY WELDING MACHINE BTMZ1800-S3

- (0 customer reviews)

- Write a product review

- Print this page

Trademark:

Product code:

Product description:

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

Input voltage (V):

MAIN PARTS

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

GENERAL INTRODUCTION

BTMZ1800- S3 is a smart gantry welding machine. It is dedicated to welding steel beam in steel structure factories Machine welds the beam in 1F posture, workpiece is stationary and welding gantry move during welding process.

BTMZ1800-S3 is suitable to weld many kind sizes of beam. Machine gains very high speed welding as a result of using 3 wires welding technology

OUTSTANDING FEATURES

- BTMZ1800-S3 applies 3-wires arc welding technology developed by BRUCO for better welding quality and higher welding speed. When machine welds thin beams, K≤10, the machine uses 2 wires Ø 1.6 welding mode. When machine welds thick beams K> 19, the machine automatically switches to 3-wires arc welding mode (wire Ø4.0 go first to creat deep penetration, 2 wires Ø1.6 go after to creat coating). Web height is 1800mm maximum

- The machine is equipped smart welding controller with touch screen, able to program, manage information, store data, connect Ethernet, report errors …

- The machine is pre-installed with an optimal set of welding parameters to support effectively the operation process and minimize errors when setting parameters by operators

- BTMZ1800- S3 has a monitoring user function to help evaluate performance. It can be a timekeeping, report the machine condition, actual welding time and time when turn on the machine but not welding …

PARAMETERS

| No | Items | Unit | Parameters |

| 1 | Flange Width | mm | 200~800 |

| 2 | Web height | mm | 200~1800 |

| 3 | Welding flux hopper capacity | kg | 2*50 |

| 4 | Rail span | mm | 1500 |

| 5 | Welding speed | mm/min | 240-1700 |

| 6 | Welding position | 1F | |

| 7 | Welding wire diameter ( 2wires back) | mm | Ø 1.6 |

| 8 | Welding wire diameter (1wire front) | mm | Ø 2.4 – Ø 4.0 |

| 9 | Mechanical power (not included welder) | Kw | 8.24 |

| 10 | Total weight | tons | 2.8 |

| 11 | Power Supply | 3 Phases 4 wires, 380/50 V/Hz |

SMART GANTRY WELDING MACHINE BTMZ1800-S3

(0 customer reviews)Customers comment on the product

Related products

The SMART HORIZONTAL WELDING MACHINE HN0630-S2 is the unique machine on the market that can weld multiple types of beams, including straight beams and specially shaped profiles such as A-shaped and K-shaped beams.

- Integrating 3 functions of attaching, welding and straightening on the same body system, is a solution to flexibly meet the needs of customers, helping to increase productivity, optimize space and cost

- The body is sturdy and stable

- Using Tandem MIG 2-wire technology under the drug layer for high speed and weld quality

- The welding source used for the machine is a welding source for robots with many advantages such as a wide, stable and durable input voltage range. The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and ensuring the quality of the weld.

Input voltage (V):3 pha 380 VAC

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

Model: LC26035XD

Brand: BRUCO

Laser Source: MAX 20000W

Controller: FSCUS 10000

Warranty: 24 months for laser source and machine

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.