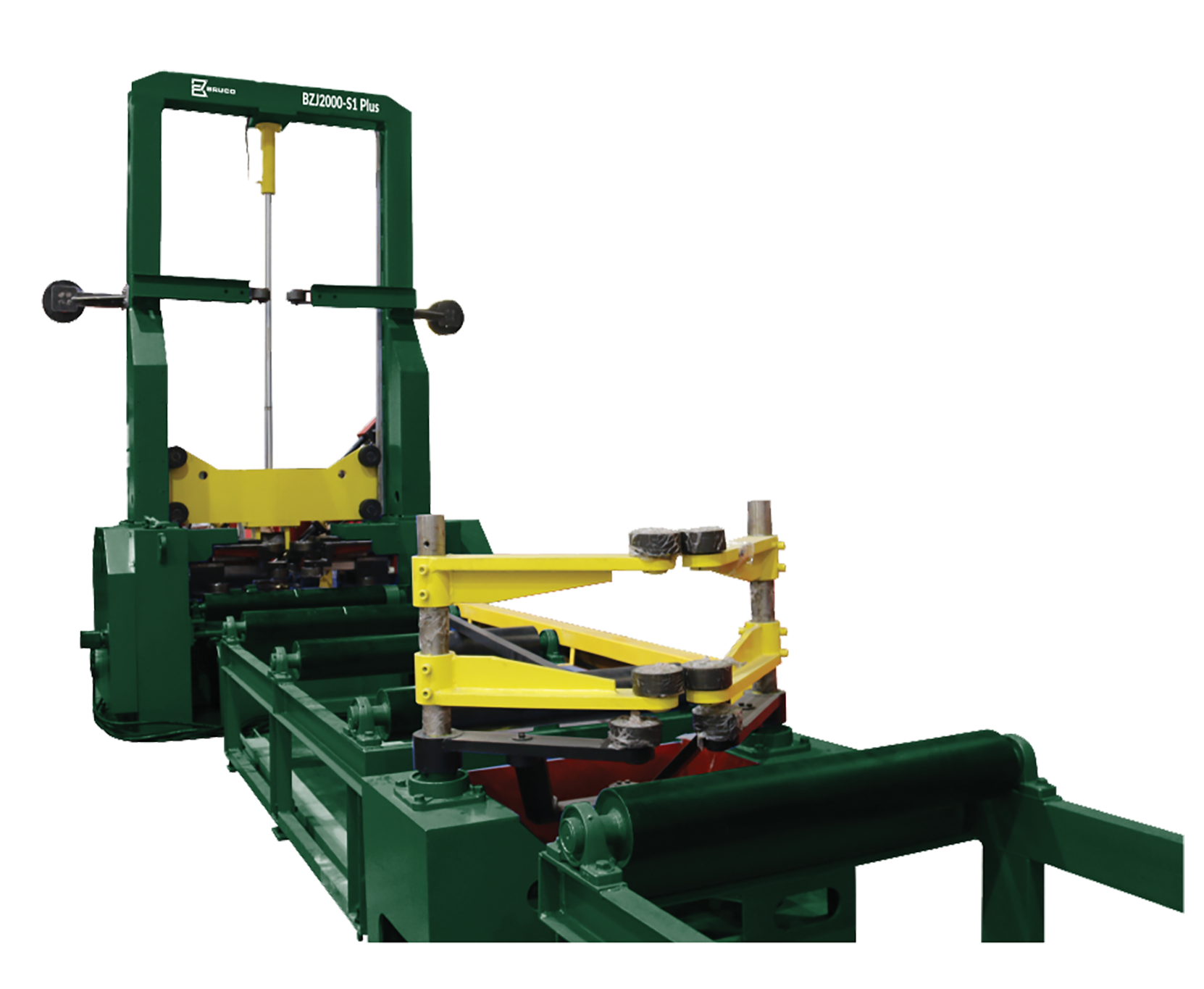

SMART H BEAM ASSEMBLING MACHINE BZJ2000-S1 PLUS

Trademark:

Product code:

Product description:

- BZJ2000-S1 Plus has a smart welding controller with interactive touch screen which is capable to program, manage information, store

data, connect Ethernet and report errors… - BZJ2000-S1 is preinstalled a set of welding / assembling parameters data. Thus, the operation process is more convenient and limits

errors when installing by operators. - BZJ2000-S1 has a monitoring user funtion to help evaluate performance.

- Centering pulling rod system includes 4 rollers (press flange) and 8 rollers (press web), moves by screw and slider to get high accuracy.

- Guide roller of compression cylinder is designed large size, strong, stable and easy to adjust.

- Welding torch is located at the optimal position, as a result, the assembly point is very accurate.

- Torch clamping device is designed strong and flexible ensure that the assembly point is always in the right position.

- The main motor locates under the machine body to save space and keep safely when operating.

- Hydraulic system is compact with only 160L oil tank.

- 30% higher productivity compared to normal machines

Input voltage (V):

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.