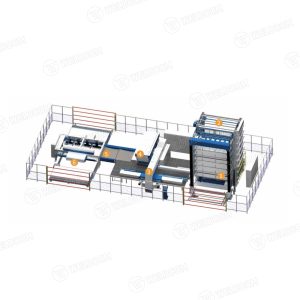

The laser blanking line utilizes laser cutting technology to achieve die-less production. The laser cutting system features rapid layout and changeover capabilities, allowing it to process different material sheets with unlimited product contour lines. It can easily adjust parameters for material pieces, continuously optimize geometric shapes and accuracy, achieve uninterrupted cutting and offloading, and quickly switch between batches. This system can rapidly adapt to changes in automotive production volume, thereby increasing material utilization through nested production in the blanking process

MAIN FUNCTIONS AND FEATURES

- High degree of automation

- Roll cassette quick change roll precision straightening technology.

- Special blanking press, high rigidity, high precision, high efficiency.

- Press anti-eccentric load technology.

- High material utilization.

- Magnetic and vacuum stacking facing different sheets.

- Blanking and stacking of parts of various shapes can be realized.

- Exact length.

- Anti-Scratch Technology.

- Press Heavy Duty Lubrication System.

Related products

The plate face punching unit (FMC) has the functions of automatic feeding, punching and automatic loading and unloading and stacking.

The purpose of this processing system is to increase flexibility and automate the production of large flat sheet metal parts such as elevator doors and vehicle walls. The whole system includes: the raw material is selected by the automatic bar feeding system and transferred to the CNC punching machine to complete the punching process.

The long and short sides of the plate are bent using two gantry bending robots and two CNC bending machines. After the short edges are folded, they are transferred to the welding line to complete the rebar resistance welding, servo arc welding at the overlapping edges of the reinforcement ribs and bottom plate. The robot spot welds the overlapping edges of the bottom plate and stacks them on wooden pallets.

The automatic laser cutting line provided by Yawei can be used as a smart sheet metal factory device to communicate and share data with the ERP/MES production management center during processing. according to the production plan.

- Automatically complete loading, cutting and unloading of billets

- Perform batch and continuous processing of single sized billets

- The system consists of a punching and cutting machine combined with an intelligent material library, a bar feeding device, and an automatic product sorting and stacking device.

- Centralized control system can control each device to maximize the processing efficiency of the system.

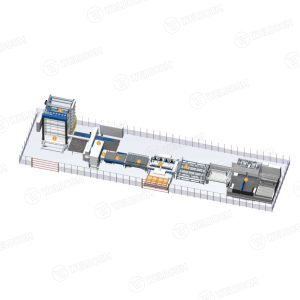

AMS.HSP sheet metal punching, cutting and bending combination line, integrated punching unit and cutting unit, bending unit to perform the entire process of punching, cutting, bending and folding automatically

- Billing Truck

- Automatic loading and unloading equipment

- Laser cutting machine

- Finished trolley

Sheet metal automatic processing production line is a compact and flexible production line that integrates three-dimensional warehouse, CNC punching and cutting unit, pallet divider, turning device and needle folding unit.

CNC plate type, can automatically punch flat holes. The entire production line has large production capacity and small scale, and can realize fully automated material handling and high flexibility without manual intervention.

The 3-in-1 CNC punching line combines automatic billet loading and unloading, integrating the advantages of punching and laser cutting processing.

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.