- Compact design, flexible, easy to operate and highly efficient

- The machine has 2 operating modes Auto and Manual, using PLC convenient for workers to operate, with anti-clogging sensor.

- There are 02 high-capacity vacuuming silos, each silo has 9 dust filters, ensuring maximum dust collection during work (without affecting the environment).

- The machine uses Q034 turbine with high cleaning efficiency, low noise

Khối lượng:> 100 Kg

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets MZ1000 Jasic.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

The SMART HORIZONTAL WELDING MACHINE HN0630-S2 is the unique machine on the market that can weld multiple types of beams, including straight beams and specially shaped profiles such as A-shaped and K-shaped beams.

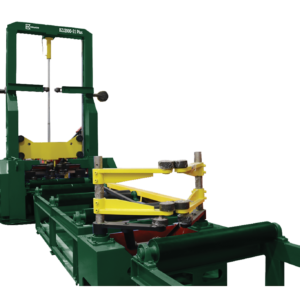

- BZJ2000-S1 Plus has a smart welding controller with interactive touch screen which is capable to program, manage information, store

data, connect Ethernet and report errors… - BZJ2000-S1 is preinstalled a set of welding / assembling parameters data. Thus, the operation process is more convenient and limits

errors when installing by operators. - BZJ2000-S1 has a monitoring user funtion to help evaluate performance.

- Centering pulling rod system includes 4 rollers (press flange) and 8 rollers (press web), moves by screw and slider to get high accuracy.

- Guide roller of compression cylinder is designed large size, strong, stable and easy to adjust.

- Welding torch is located at the optimal position, as a result, the assembly point is very accurate.

- Torch clamping device is designed strong and flexible ensure that the assembly point is always in the right position.

- The main motor locates under the machine body to save space and keep safely when operating.

- Hydraulic system is compact with only 160L oil tank.

- 30% higher productivity compared to normal machines

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

- Fast tool change speed

- Tool change time T-T: VTX 5A/7A: T-T = 0.8s VTX 5/7: T-T – 1.2s

- High rigidity guide rail system

- Direct drive spindle motor, allowing quick acceleration/deceleration, hard tap up to 6000rpm

- Spindle diameter up to 50mm, increase rigidity when tar

Khối lượng:> 100 Kg

- Tool change speed, tool change time T-T: 1-2s

- Servo motor-driven tool change system/ enables quick tool change

- Direct drive spindle motor, allowing quick acceleration/deceleration, hard tap up to 6,000rpm

- No-load travel speed up to 60m/min, acceleration up to 1.2G

- Maximum spindle speed reaches 24,000rpm

Khối lượng:> 100 Kg