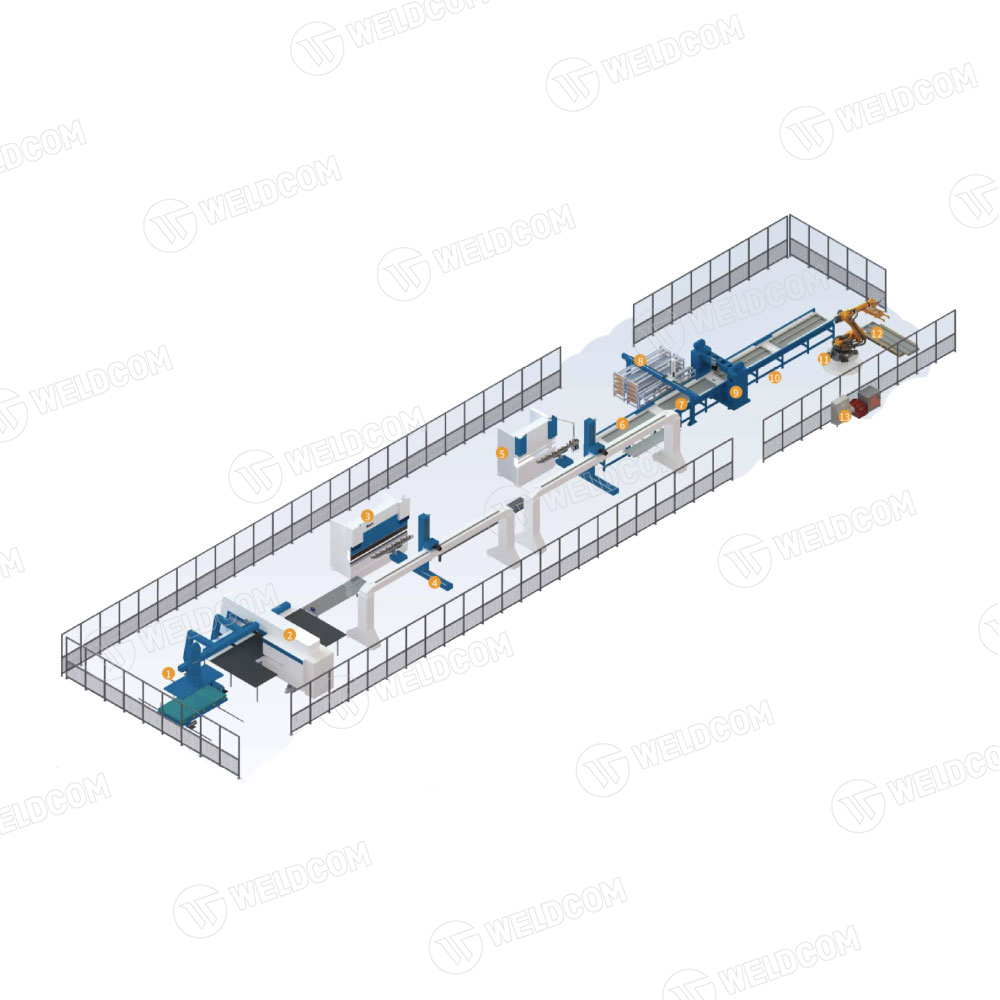

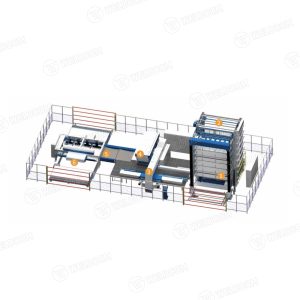

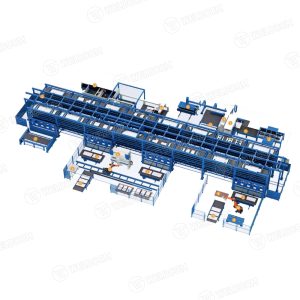

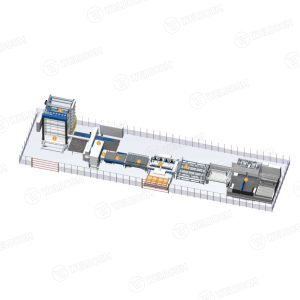

Elevator door production line

Trademark:

Product code:

Product description:

The purpose of this processing system is to increase flexibility and automate the production of large flat sheet metal parts such as elevator doors and vehicle walls. The whole system includes: the raw material is selected by the automatic bar feeding system and transferred to the CNC punching machine to complete the punching process.

The long and short sides of the plate are bent using two gantry bending robots and two CNC bending machines. After the short edges are folded, they are transferred to the welding line to complete the rebar resistance welding, servo arc welding at the overlapping edges of the reinforcement ribs and bottom plate. The robot spot welds the overlapping edges of the bottom plate and stacks them on wooden pallets.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.