WELDING ROBOT ABB IRB 4600

- (0 customer reviews)

- Write a product review

- Print this page

Product code:

Product description:

- Shortest cycle times

- Ultra-wide working range

- Small footprint

- Best protection available

- Cleanroom option

New Design. New Features. New Technologies

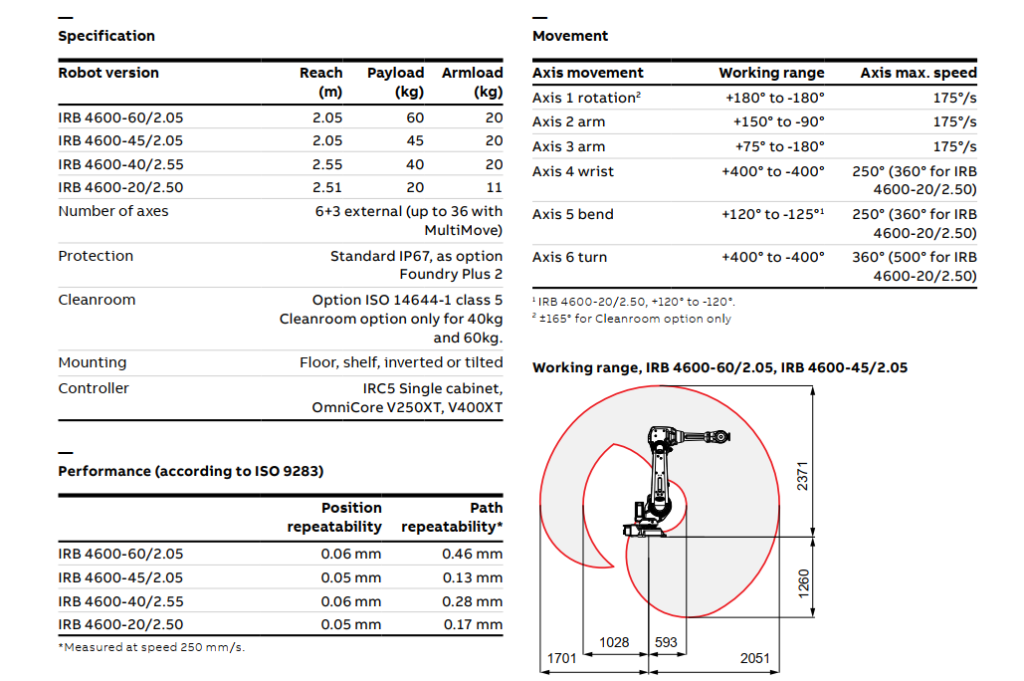

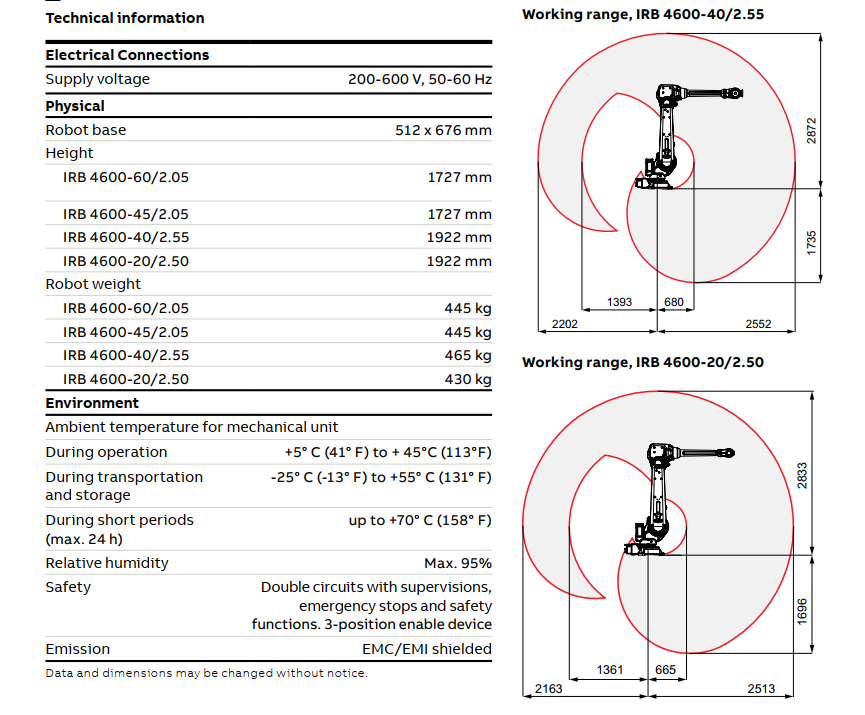

IRB 4600 is a highly productive general purpose robot optimized for short cycle times where compact robots can help create high density cells. The IRB 4600 enables more compact manufacturing cells with increased production output and higher quality – and that means improved productivity.

Shortest cycle timesThanks to the new compact and optimized design resulting in a low weight, the IRB 4600 can cut the cycle times of the industry benchmark by up to 25%. The maximum acceleration achievable is highest in its class, together with high maximum speeds. With the high acceleration it is possible to use to avoid obstacles or to follow the path. The benefit is increased production capacity and higher productivity.

Ultra-wide working range

You can position the IRB 4600 in the most favorable way with regard to reach, cycle time and auxiliary equipment. Flexible mounting with floor, tilted, semi shelf or inverted mounting is very useful when you are simulating the best position for your application.

Small footprint

The small footprint, the slim swing base radius around axis 1, the fine elbow behind axis 3, the small lower and upper arms, and the compact wrist all contribute to the most compact robot in its class. With the IRB 4600 you can create your production cell with reduced floorspace by placing the robot closer to the served machines, which also increases your output and your productivity.

Best protection available

ABB has the most comprehensive protection program on the market and it will be even further enhanced with the IRB 4600. Foundry Plus includes IP 67, resistant paint, rust protected mounting flange and protection for molten metal spits on non-moving cables on the rear of the robot and extra protection plates over the floor cable connections on the foot.

Cleanroom option

The IRB 4600 cleanroom robot is sealed or covered (only 40 and 60 kg version), reducing particle contamination, and preventing grease and oil leakage into production areas. IRB 4600 cleanroom robot is ISO 14644-1 Class 5 certified (only 40 and 60 kg version), making it ideal for manufacturing settings requiring exceptional cleanliness and minimal particle emission.

The integrated software options for SMAROBICS include:

- 16 I.O

- PC Interface

- Optical Tracking Arc

- Multitasking

- Arc 6

- Weldguide Basic

- SmarTac

- Path Offset

- BullsEye

WELDING ROBOT ABB IRB 4600

(0 customer reviews)Customers comment on the product

Related products

The automatic laser cutting line provided by Yawei can be used as a smart sheet metal factory device to communicate and share data with the ERP/MES production management center during processing. according to the production plan.

- Automatically complete loading, cutting and unloading of billets

- Perform batch and continuous processing of single sized billets

The purpose of this processing system is to increase flexibility and automate the production of large flat sheet metal parts such as elevator doors and vehicle walls. The whole system includes: the raw material is selected by the automatic bar feeding system and transferred to the CNC punching machine to complete the punching process.

The long and short sides of the plate are bent using two gantry bending robots and two CNC bending machines. After the short edges are folded, they are transferred to the welding line to complete the rebar resistance welding, servo arc welding at the overlapping edges of the reinforcement ribs and bottom plate. The robot spot welds the overlapping edges of the bottom plate and stacks them on wooden pallets.

- Neat design

- Flexibility in installation

- Exceptional accuracy and speed

- Easy to use, easy to install

- Safe and intelligent mine anti-collision function.

- Shorter cycle times

- Faster programming

- Reduced cost of ownership

- Higher output from a smaller footprint

- Increased agility in smaller spaces

The 3-in-1 CNC punching line combines automatic billet loading and unloading, integrating the advantages of punching and laser cutting processing.

The plate face punching unit (FMC) has the functions of automatic feeding, punching and automatic loading and unloading and stacking.

The punching unit of the punching machine has the functions of automatic billet feeding, punching and automatic loading and unloading and stacking. Feeding and unloading devices are located on both sides of the machine, which has strong scalability and high efficiency.

- Billet trolley

- Barrel feeding device

- CNC punching machine

- Billet unloading device

- Product lifting and unloading equipment

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.