THROUGH-TYPE GANTRY WELDING PLATFORM – CH14TD

- (0 customer reviews)

- Write a product review

- Print this page

GENERAL INTRODUCTION

The only machine in Vietnam developed by Bruco specificallyfor welding steel pipes with a diameter of up to 14m. It ensures high-quality welds, and productivity, minimizes intermediate steps, and is primarily applied in the national wind power industry

MAIN PART

- Main Machine: The welding gate with a flexible lifting and lowering mechanism allows easy adjustment of the diameter of the workpiece from 4000mm to 14000mm.

- The integrated welding head includes an automatic lifting and lowering system with a touch sensor.

- The automatic exhaust and fume recovery system helps prevent welding fume loss due to scattering.

- Control System: The intelligent control system can store various welding programs.

- It utilizes the control unit and user interface screen from KEYENCE, supporting both English and Vietnamese languages.

- Welding Power Source: The Tandem welding power source of a leading 1250A DC welding source and a trailing AC/DC 1000A welding source

OUTSTANDING FEATURES

- Integrated adaptive welding head adjustment system optimizes technology to ensure welding compatibility with various pipe sizes.

- Applies Tandem welding technology under the flux layer for fast welding speed and high-quality welds. The welding power source is specifically designed for Tandem welding, offering advantages such as a wide input voltage range, stability, and durability.

- Comes pre-installed with welding DATA sets, providing maximum support during operation, easy training for operators, and optimizing labor costs.

- Integrated Ethernet IP connection to link with SCADA or MES systems. Machine data will be sent to the server for comprehensive reporting by shift/day/month/quarter, evaluating the machine’s performance and workforce efficiency

TECHNICAL DATA

| No | MODEL | Unit | Parameters |

| 1 | Power supply | V/Hz | 3 phase, 380-400V, 50Hz |

| 2 | Rail | P43 | |

| 3 | Distance between 2 rail | m | 15 |

| 4 | Working floor | m2 | >28 |

| 5 | Motor for moving the gate & lifting & lowering the product | Variable frequency control | |

| 6 | Working height | m | 4 – 16 |

| 7 | Travel speed on the beam | m/ phút | 0.4 – 1.2 |

| 8 | Working floor lifting speed | m/ phút | 0.4 – 1.0 |

| 9 | Diameter of the product that can be welded | mm | 4000 – 14000 |

| 10 | Welding torch cluster | TANDEN SAW welding torch welding 2 wires with diameters (3.2mm/4.0mm/4.8mm) | |

| 11 | Welding powder discharge and recovery mechanism | Automatic (Motor power for recovering powder is 3kw, welding powder box is 50kg) | |

| 12 | Welding position detection mechanism | Contact mechanism (mechanical detection), self-adjusting position distance: 200mm. The mechanism consists of X, Y axes | |

| 13 | Weatherproof canopy | set | Yes |

| 14 | Maintenance and operation ladder | mm | 2 ladders |

| 15 | Control cabinet | kw | KEYENCE/MITSUBISHI |

| 16 | Gate travel distance | Fixed/movable | |

| 17 | Automatic welding powder suction unit | 1 | |

| 18 | Welding wire diameter | 2.4 – 4.8 | |

| 19 | Main machine power | ≥ 28,6 |

THROUGH-TYPE GANTRY WELDING PLATFORM – CH14TD

(0 customer reviews)Customers comment on the product

Related products

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

- Machine frame: 01 set

- Welding torch and center pulling rod system: 02 sets.

- Welding guide device: 02 sets

- Flux recovery system: 02 sets.

- Welding source: 4 sets Megmeet Artsen CM500R and 2 sets Jasic MZ1000.

- Control system: 01 control cabinet, 01 control handle.

- Hose and cable system

- Laser sensor and Servo motor ensure high-quality weld seams.

- Smart welding torch assembly – supports 2F, 1F, and 1G positions, compatible with various beam types.

- Laser seam tracking with automatic flux feeding and recovery system.

- Optimized investment cost.

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

The SMART HORIZONTAL WELDING MACHINE HN0630-S2 is the unique machine on the market that can weld multiple types of beams, including straight beams and specially shaped profiles such as A-shaped and K-shaped beams.

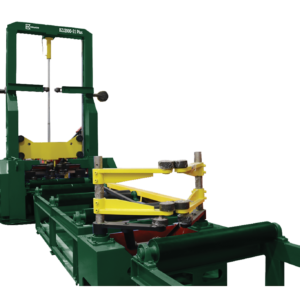

- BZJ2000-S1 Plus has a smart welding controller with interactive touch screen which is capable to program, manage information, store

data, connect Ethernet and report errors… - BZJ2000-S1 is preinstalled a set of welding / assembling parameters data. Thus, the operation process is more convenient and limits

errors when installing by operators. - BZJ2000-S1 has a monitoring user funtion to help evaluate performance.

- Centering pulling rod system includes 4 rollers (press flange) and 8 rollers (press web), moves by screw and slider to get high accuracy.

- Guide roller of compression cylinder is designed large size, strong, stable and easy to adjust.

- Welding torch is located at the optimal position, as a result, the assembly point is very accurate.

- Torch clamping device is designed strong and flexible ensure that the assembly point is always in the right position.

- The main motor locates under the machine body to save space and keep safely when operating.

- Hydraulic system is compact with only 160L oil tank.

- 30% higher productivity compared to normal machines

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.