WMMS (Weldcom Monitoring Machine and Maintenance Management System) is an advanced software system that provides comprehensive support in managing equipment performance and maintenance for manufacturing enterprises. The system powerfully integrates modern technologies such as AI and IoT to monitor, analyze, and optimize the entire maintenance process-from planning and execution to performance monitoring.

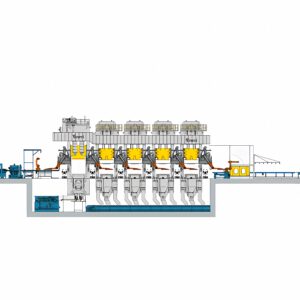

SMARLINEiQ is a breakthrough solution that enables manufacturers to transition from traditional production models with isolated automation systems to a fully integrated, flexible, and intelligent production line.

- Integrating 3 functions of attaching, welding and straightening on the same body system, is a solution to flexibly meet the needs of customers, helping to increase productivity, optimize space and cost

- The body is sturdy and stable

- Using Tandem MIG 2-wire technology under the drug layer for high speed and weld quality

- The welding source used for the machine is a welding source for robots with many advantages such as a wide, stable and durable input voltage range. The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and ensuring the quality of the weld.

- Laser sensor and Servo motor ensure high-quality weld seams.

- Smart welding torch assembly – supports 2F, 1F, and 1G positions, compatible with various beam types.

- Laser seam tracking with automatic flux feeding and recovery system.

- Optimized investment cost.

- Integrating a set of optimal welding heads in terms of technology and size, ensuring that a variety of beam sizes can be welded.

- Using 2-wire 2 independent arc welding technology with 04 (or 08) Artsen CM500R Megmeet welding sources, with a large welding data system, automatically calculating welding parameters. Optimum user action on the touch screen control panel.

- Application of Tandem MIG welding technology under the drug layer for fast welding speed, high weld quality. Welding source is a source for robots with many advantages such as wide input voltage range, stability, and durability.

- The wire feed of the welding source has an Encoder that controls the wire speed, making the welding current stable and the highest quality weld.

- Pre-installed welding DATA kit, maximum support during operation, easy training of operators, optimizing labor costs.

- Equipped with user data monitoring to help evaluate work efficiency. Measure parameters of welding meters, welding time, machine downtime for each production shift.

- The machine has built-in Ethernet IP connection to connect to SCADA or MES systems. The data in the machine will be sent to the server to give aggregates and display reports by shift/day/month/quarter

- Shortest cycle times

- Ultra-wide working range

- Small footprint

- Best protection available

- Cleanroom option

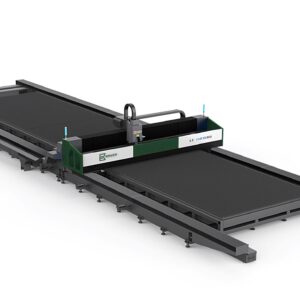

Model: LC26035XD

Brand: BRUCO

Laser Source: MAX 20000W

Controller: FSCUS 10000

Warranty: 24 months for laser source and machine

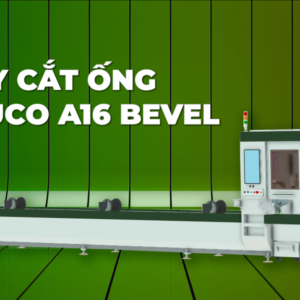

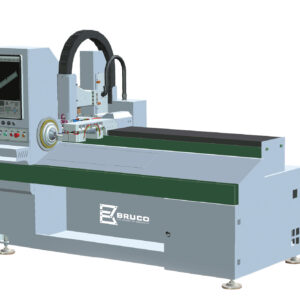

- Suitable for cutting medium and small pipes.

- Efficient cutting with high precision.

- Optimizes investment costs.

- Compact machine size, saves workshop space.

- 2-year warranty.

Tiếng Việt

Tiếng Việt