WELDCOM MONITORING MACHINE AND MAINTENANCE MANAGEMENT SYSTEM – WMMS

- (0 customer reviews)

- Write a product review

- Print this page

Product code:

Product description:

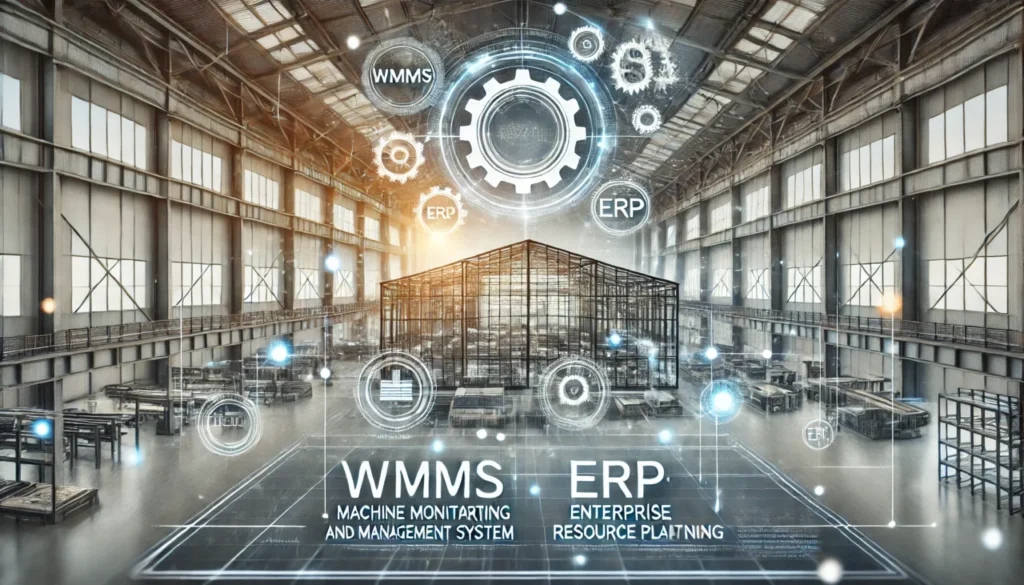

WMMS (Weldcom Monitoring Machine and Maintenance Management System) is an advanced software system that provides comprehensive support in managing equipment performance and maintenance for manufacturing enterprises. The system powerfully integrates modern technologies such as AI and IoT to monitor, analyze, and optimize the entire maintenance process-from planning and execution to performance monitoring.

WMMS (Weldcom Monitoring Machine and Maintenance Management System) is an advanced software system that provides comprehensive support in managing equipment performance and maintenance for manufacturing enterprises. The system powerfully integrates modern technologies such as AI and IoT to monitor, analyze, and optimize the entire maintenance process-from planning and execution to performance monitoring.

The adoption of the WMMS solution not only helps reduce unexpected downtime but also optimizes resources, extends equipment lifespan, and improves asset management efficiency within enterprises.

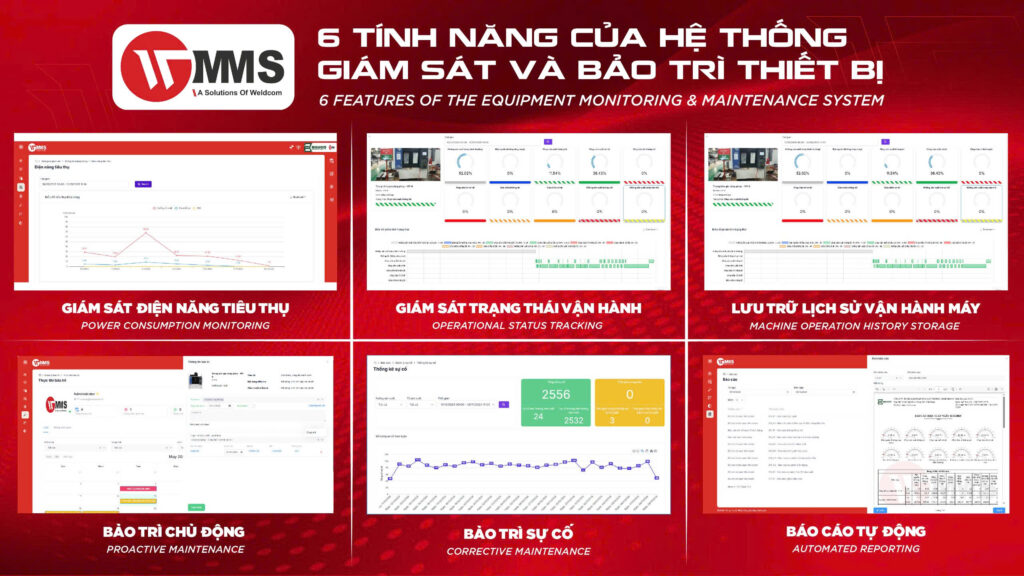

6 Key Features of WMMS

1. Operational Status Monitoring

Enables real-time monitoring of equipment operating conditions.

Detects abnormal signs promptly, improving reliability and extending machine lifespan.

2. Power Consumption Monitoring

Collects and analyzes power consumption data for each piece of equipment.

Helps optimize energy efficiency and control operating costs.

3. Digitized Records and Equipment Operation History Storage

Digitizes machine records: technical documents, installation manuals, operation guides, maintenance instructions, etc.

Records complete information on equipment operation, including runtime, downtime, and errors.

Supports quick access for troubleshooting, failure analysis, or performance evaluation.

4. Preventive Maintenance

Provides tools for scheduling maintenance based on time or usage cycles.

Minimizes breakdown risks, improves performance, and extends equipment lifespan.

5. Corrective Maintenance

Allows logging, handling, and tracking of the entire repair process in case of unexpected failures.

Ensures timely response and minimizes downtime.

6. Automated Reporting

Automatically generates comprehensive reports related to equipment operation and maintenance.

Key functions include:

Analytics: Evaluates performance, consumption trends, and equipment lifespan.

Alerts: Sends notifications when abnormal indicators or threshold violations are detected.

Outstanding Benefits of WMMS in Equipment Maintenance Management

Reduced Maintenance Costs

Analyzes historical data to detect potential issues early, preventing major breakdowns.

Promotes preventive repairs instead of full replacements, leading to significant cost savings.

Production Continuity

Conducts scheduled maintenance to minimize unplanned downtime.

Ensures continuous and stable production processes.

Increased Productivity

Provides effective tools for task management and progress tracking.

Enables staff to easily access information and guidelines to complete tasks efficiently.

Asset and Data Tracking

Stores and manages comprehensive asset information, including technical specifications, locations, and operational history.

Facilitates better asset and production data management.

Enhanced Workplace Safety

Closely monitors maintenance activities related to occupational safety.

Minimizes accident risks and fosters a safer, more secure working environment.

WELDCOM MONITORING MACHINE AND MAINTENANCE MANAGEMENT SYSTEM – WMMS

(0 customer reviews)Customers comment on the product

Related products

Smarobics is an intelligent 3D mechanical design and robot control software platform, specifically developed for welding robots across a wide range of applications.

SMARLINEiQ is a breakthrough solution that enables manufacturers to transition from traditional production models with isolated automation systems to a fully integrated, flexible, and intelligent production line.

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.