SMART SOFTWARE POWERING FLEXIBLE PRODUCTION LINES – SMARLINEiQ

- (0 customer reviews)

- Write a product review

- Print this page

Product code:

Product description:

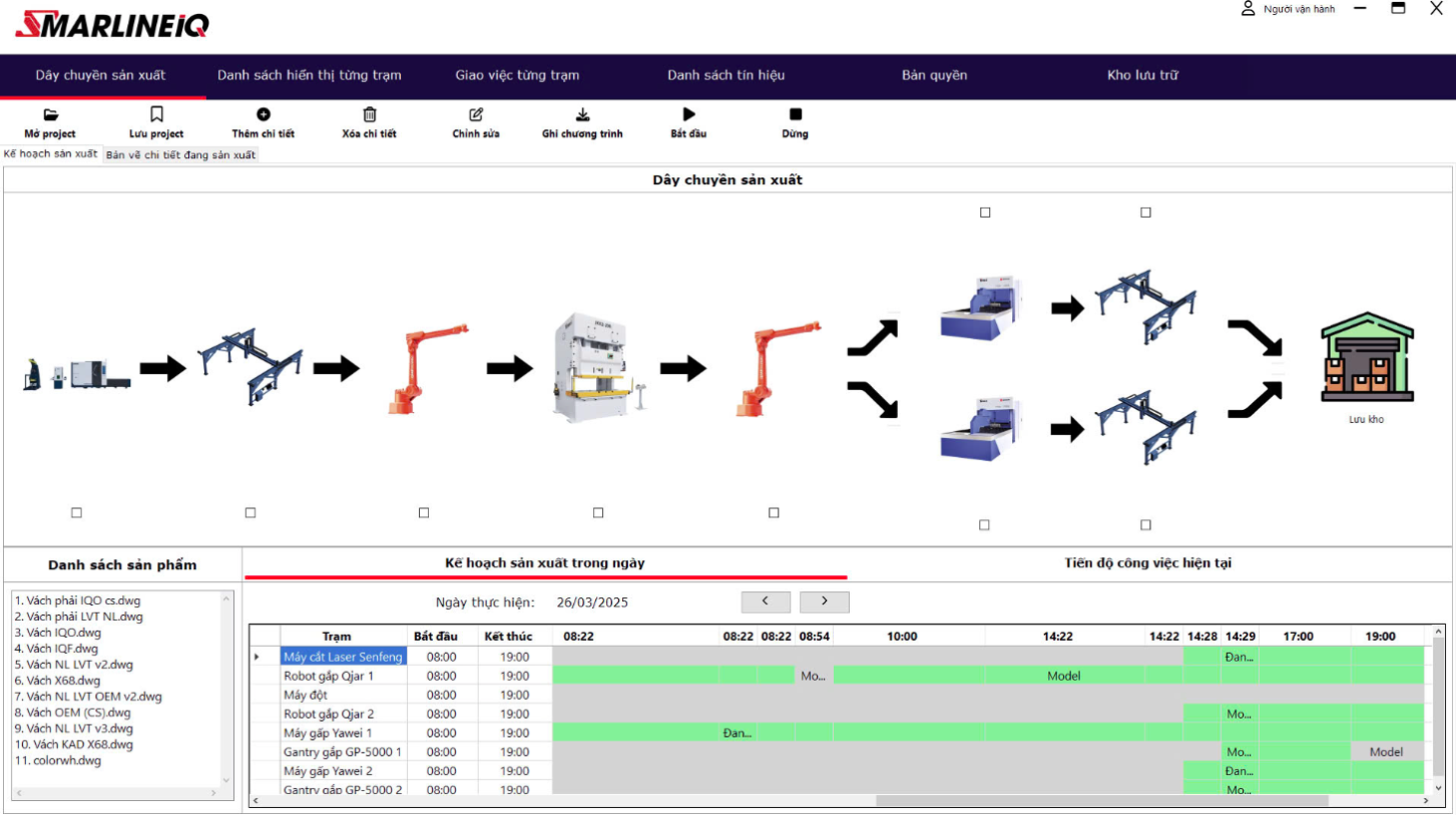

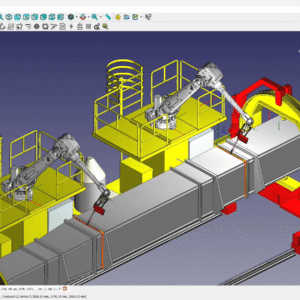

SMARLINEiQ is a breakthrough solution that enables manufacturers to transition from traditional production models with isolated automation systems to a fully integrated, flexible, and intelligent production line.

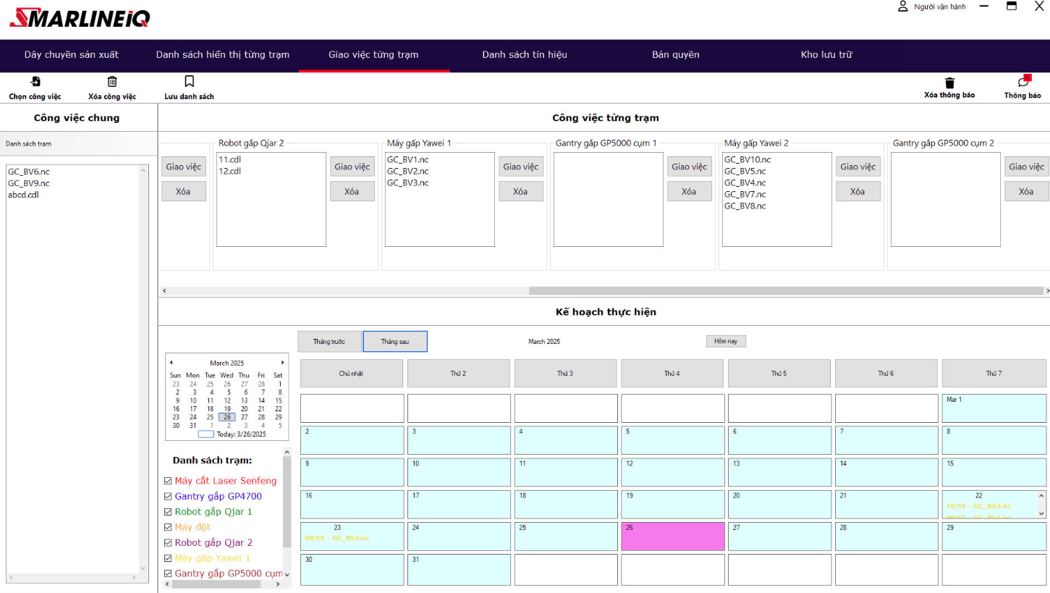

integrates a comprehensive suite of production coordination features—from receiving design drawings and assigning machining tasks, to robot control, equipment monitoring, data collection, and AI-powered intelligent alerts. This solution is well-suited for factories in steel structure fabrication, infrastructure, automotive, shipbuilding, and related sectors. It helps enhance productivity, control project timelines and quality, and optimize long-term operational costs.

According to the Vietnam Association of Mechanical Industry (VAMI), the country currently has approximately 3,100 mechanical manufacturing enterprises and over 53,000 production facilities, accounting for nearly 30% of all enterprises in the processing and manufacturing sectors. In recent years, Vietnam’s mechanical industry has seen positive developments—gradually mastering technology, increasing the rate of localization, and expanding its market. However, a major bottleneck remains in technological capabilities: 60–70% of domestic mechanical firms still operate at an average level, while only 30–40% have access to more advanced technologies.

In practice, many companies face a range of barriers—from inflexible management systems and outdated machinery that cannot be networked, to high investment costs for automation. Additionally, the lack of intelligent monitoring tools leaves manufacturers unprepared to respond promptly to unexpected incidents during production. Recognizing these “pain points,” Weldcom developed SMARLINEiQ to help transform manual production models into smart, flexible, and automated manufacturing systems.

INTEGRATED MODULES FOR END-TO-END MANUFACTURING SUPPORT

The software includes a library of APIs that form an open architecture, allowing third-party developers to integrate their own machines, services, or software into the SMARLINEiQ platform. It supports integration with Smarobics—an intelligent robot control system—as well as CAD/CAM software for generating automated CNC programs (milling/turning), and Nesting/Sigmanest for coil-fed laser systems to optimize cutting layouts and reduce material waste.

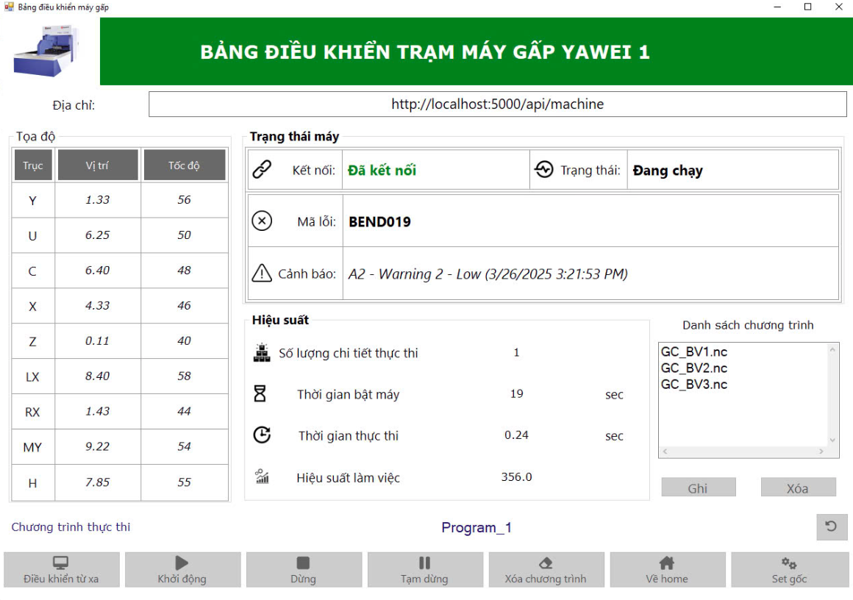

SMART MONITORING SYSTEM AND FAULT ALERTS

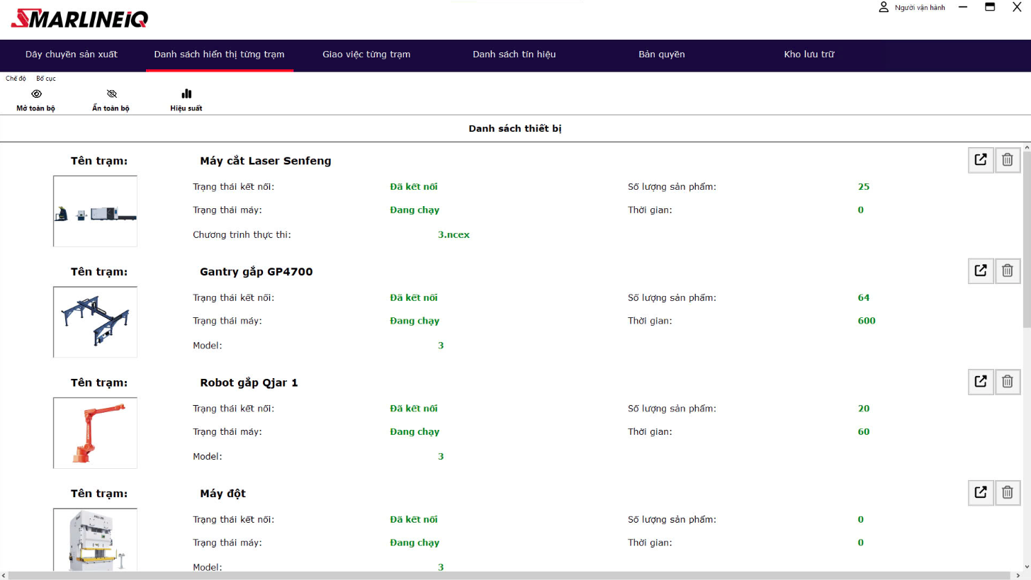

SMARLINEiQ functions as an independent monitoring layer that supports sensor networks and equipment PLCs. It automatically manages and synchronizes operations across all machines, preventing bottlenecks or product backlog. In the event of anomalies—such as collisions or sudden machine stoppages—the system immediately triggers alerts and adjusts operational speed to minimize disruptions, allowing technicians to respond quickly.

REAL-TIME OPERATIONAL MONITORING AND PERFORMANCE EVALUATION

The system continuously monitors equipment status, tracking output volumes, operational time (running/stopped/fault), and stage-level performance metrics. These data provide a solid foundation for evaluating actual productivity versus planned targets—empowering management to make informed decisions for continuous improvement and process optimization.

SMART SOFTWARE POWERING FLEXIBLE PRODUCTION LINES – SMARLINEiQ

(0 customer reviews)Customers comment on the product

Related products

Smarobics is an intelligent 3D mechanical design and robot control software platform, specifically developed for welding robots across a wide range of applications.

WMMS (Weldcom Monitoring Machine and Maintenance Management System) is an advanced software system that provides comprehensive support in managing equipment performance and maintenance for manufacturing enterprises. The system powerfully integrates modern technologies such as AI and IoT to monitor, analyze, and optimize the entire maintenance process-from planning and execution to performance monitoring.

VIEWED PRODUCTS

You have not viewed any product yet!

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.