PARTNERS & CUSTOMERS

STRATEGIC PARTNERS

HURCO

In the field of machine tool manufacturing, there are many companies and corporations that stand out as “big boss” that are hard to replace. One of them is Hurco – America’s Top 1 manufacturer of machine and tool equipment, highly appreciated and well received by the mechanical world. The following article will help readers better understand this famous brand.

Thương hiệu HURCO

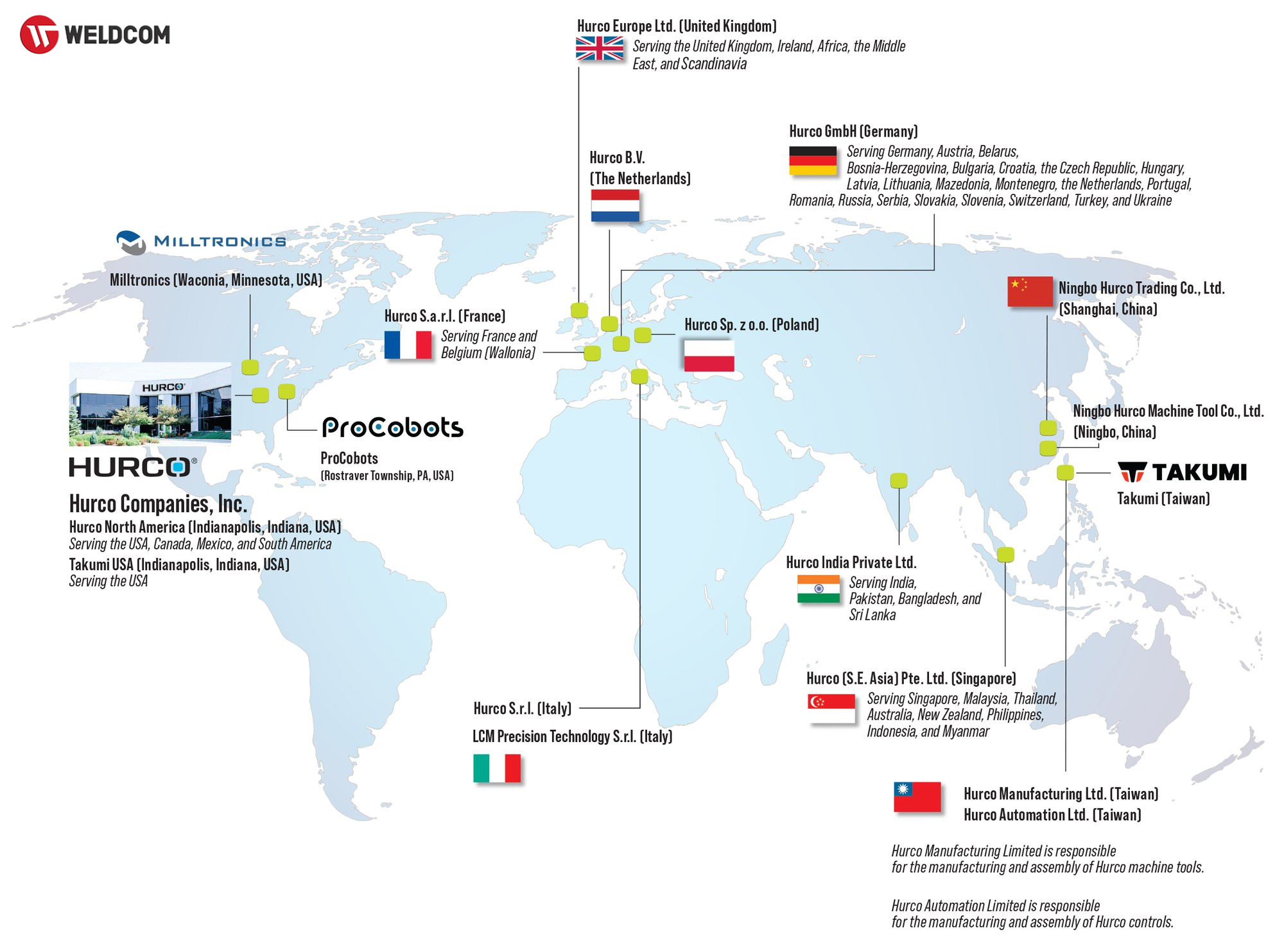

HURCO is a corporation specializing in manufacturing machines and industrial equipment for the precision mechanical field, established in 1968 and headquartered in Indianapolis, USA. According to Technavio’s 2020 market research report, Hurco ranks 4th in the list of leading precision machining machine manufacturers in the world, behind DMG Mori, Yamazaki Mazak and Okuma.

Currently, Hurco owns 3 manufacturing plants located in 3 countries, USA, Italy and Taiwan. The Group has merged two more brands Takumi, Miltronics and established 12 representative offices spread worldwide a full range of experienced human resources ready to provide before- during- after- sales service.

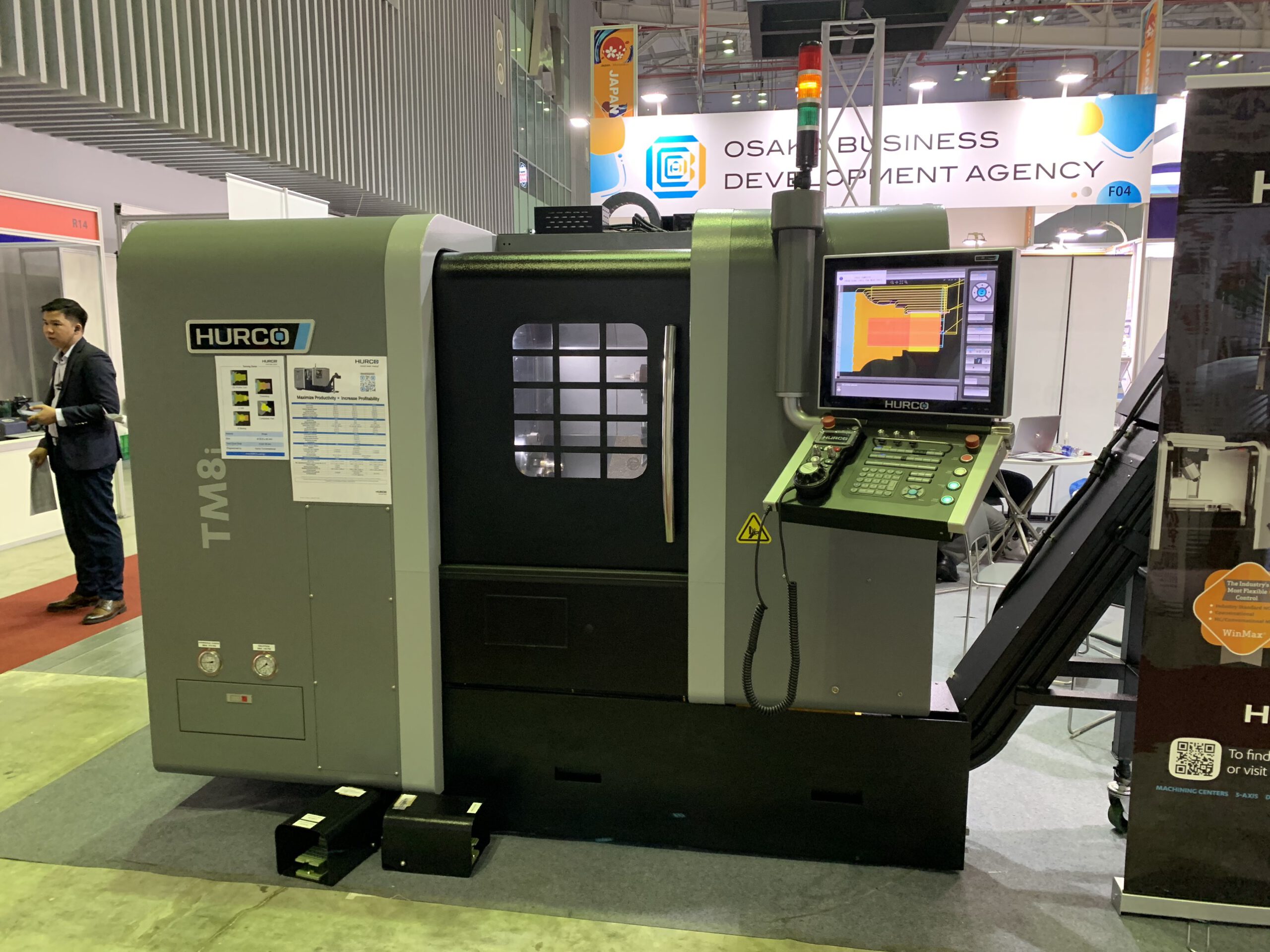

In the range of equipment in the field of precision mechanics, Hurco mainly focuses on two lines of CNC milling machines and CNC lathes for stability and high accuracy, suitable for enterprises producing auxiliary industries, metal processing, stonework, mold making to applications requiring high precision such as aeronautics – space, defense, etc

Product made by Hurco CNC lathe with high precision

Hurco is also a technology master when it always tries to research and improve to integrate modern technology into each product to improve performance through WinMax controller. This part has a compact design but possesses many outstanding features that allow users to flexibly select modes suitable for the purpose of processing finished products. As a result, businesses can thoroughly solve backlog problems in production, towards creating products faster, saving machining time up to 30% and optimizing work for people.

Over the years, the Hurco corporation’s machine tool products have been present and have been chosen by consumers in the most demanding markets such as the US, Canada, Korea, Europe, etc. European region – where the standards for mechanical equipment products are judged to be strict. In addition, Hurco has also been named “Top Brand” and “Excellent Supplier” by prestigious industry organizations, such as Advanced Manufacturing Research Center (AMRC), American Machinist Magazine and Gardner Business Media. Its global sales reached $227 million (54% of sales in Europe); supplying equipment to many major partners such as Airbus, Honeywell, Caterpillar, Nasa, John Deere, Weldcom, etc. The above achievements are the clearest evidence for Hurco’s continuous development efforts.

In 2022, Weldcom has become the official authorized and warranty partner of Hurco in Vietnam market. The cooperation of the two brands will be a premise for domestic enterprises to approach and update advanced equipment and machines in order to improve technology, improve production capacity, increase competitive advantages and increase competitiveness. supporting the strong development of the current domestic precision mechanical industry.

Weldcom is the official authorized and warranty partner of Hurco in Vietnam

For more information about Hurco products, please contact Weldcom at Hotline: 19009410 or leave your information in the comment section below.

SENFENG

The enterprise owns a factory with a total area of more than 36,000m2 with many modern synchronous production and assembly lines. Annually, the production line produces a laser cutting machine output of 5000 units/year to meet the diverse needs of businesses around the world.

Senfeng Laser in Jinan, China

Besides, Senfeng also owns the most modern research and development center for products. Here, an excellent technical team has researched, evaluated, tested and put into practice Senfeng’s latest technologies. All are aimed at saving costs, optimizing productivity and quality, and promoting economic development for businesses.

Nearly 500 technical patents on high power fiber laser cutting source, fiber laser cutting head – this is a testament to Senfeng’s unwavering dedication to the mechanical industry in China. These great contributions have helped Senfeng Laser receive many noble awards such as: National Little Giant Enterprise Award, National Industrial Design Center Award, …

Not only aiming for economic development, Senfeng Laser is also a leading enterprise in the trend of “Green Industry”. The company has built an environmentally friendly production model that combines strict standards between the factors: industrial development – environmental protection – quality of human life with the goal of reducing pollution. infection and contribute to the realization of green industry in the country of billions of people.

In Vietnam market, Weldcom has chosen Senfeng Laser as a partner in the popular CNC Laser machine segment. The cooperation handshake between the two businesses is an opportunity for the domestic mechanical community, especially small and medium-sized units, to access modern technology to help improve productivity, product quality and optimize costs. operating fee.

YAWEI

With a pioneering position in the field of distribution of metalworking machines in Vietnam market, Weldcom Industrial JSC always seeks and cooperates with world-renowned suppliers to bring customers the best quality products.

Prominent among them is Yawei – the leading brand in China in the field of manufacturing metal plate processing equipment.

Yawei’s outstanding products include: punching machines, CNC brake press machines, laser cutting machines, metal automation production lines, coil processing and coil processing lines…

Over 60 years of development, with a total factory area of up to 400,000 square meters, Yawei has become the leader of China’s high-end metal forming machine tool industry and a pioneer in research, application and development. applying smart production methods to production and upgrading of products.

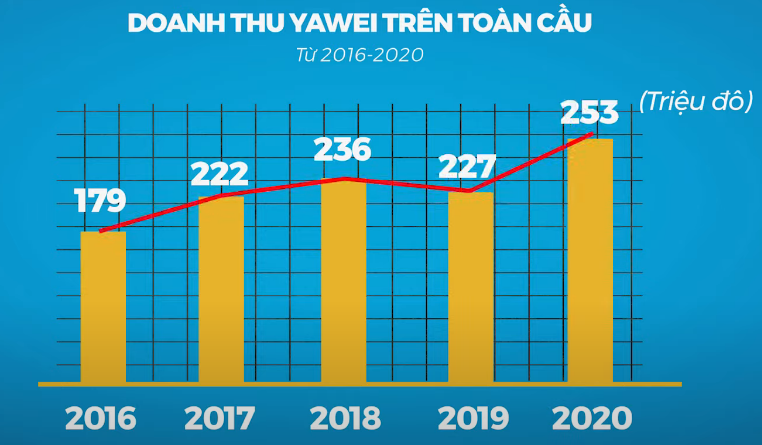

Yawei’s global revenue is constantly growing from USD 179 million in 2016 to USD 253 million in 2020.

Yawei cooperates with American, German, Dutch and Japanese firms to constantly improve to create high-quality products with more than 265 patents in the field of industrial machine manufacturing.

Yawei builds an intelligent manufacturing platform where Yawei’s products are fully integrated with the most advanced technology, with minimal human operation, using Dutch DELEM and Germany SIEMENS controllers, Japan’s NISHIBO technology for punching machines, Italy’s Prima technology for laser cutters and Swiss SMS technology for brake press machine.

Yawei is one of the few manufacturers and sellers of large capacity fiber laser cutting machines over 15KW in Vietnam as well as in the world. To produce CNC cutting machines with integrated high-power cutting sources requires very high mechanical precision and extensive experience as well as in-depth research on technology.

This is a condition that few suppliers in the world can meet. The staff at Yawei owns smart data management software and big data that allows remote prediction, maintenance, and system upgrade of CNC machines.

Currently, Yawei distributes products to more than 50 countries and regions, including many fastidious markets such as the US, Australia, Japan and European markets. Yawei supplies equipment to many major partners such as SIEMENS, IPG, Midea, HunterDouglas, Thyssenkrupp, Rheem and Weldcom.

With the spirit of creativity and innovative technology, Yawei has continuously received the following awards: China’s leading CNC machine brand, famous Chinese brand in the international market, Top 10 Chinese mechanical enterprises, National Quality Award, Most Concerned Gold Brand, First Machine Tool Company to enter the stock market…

After 6 years of presence in the Vietnamese market, Yawei has quickly received the affirmation and appreciation of customers when it has a continuous revenue growth rate of 30 to 50% a year in the period 2018 – 2020.

In 2020, Yawei’s revenue in Vietnam reached VND 231 billion. Up to now, Yawei has widely covered over 25 provinces and cities with more than 200 machines supplied to the Vietnamese market.

Since 2015, when becoming the exclusive distributor and official warranty of Yawei in Vietnam market, Weldcom has distributed Yawei products to many large-scale enterprises such as: Thanh Tien Production Commmercial Co., Ltd., , Thien Truong Manufacture and Trade Co., Ltd., Huy Thanh Mechanical and Metal Co., Ltd., Seico Steel Buildings and Equipment Industries JSC, QH PLUS Steel Structure Co., Ltd.,…

In 2022, Weldcom has built laser cutting welding & technical service development centers based in Hanoi and Ho Chi Minh City. Ho Chi Minh. The center owns a team of experienced experts along with the investment in fully and modern equipment up to tens of billions of dong to serve the repair of fiber laser sources. The launch of this center will bring many advantages in terms of after-sales technical service and save a lot of warranty and repair costs for customers using Yawei machines.

With the mission of narrowing the technology gap between the world and Vietnam, Weldcom always strives to accompany mechanical enterprises, to be a solid bridge to make Yawei brand become an important partner of many industrial companies. large production nationwide, promising to continue to develop continuously in the future.

BRUCO

Brand: Bruco

Gantry Welding Machines HN0630 – S2F

Dai Dung Trading Construction Mechanical Joint Stock Company

Manh Cuong Trading Construction Mechanical Joint Stock Company

With the mission of narrowing the technology gap between the world and Vietnam, Weldcom always strives to accompany mechanical enterprises, to be a solid bridge to make Bruco brand become an important partner of many industrial companies. large production nationwide, promising to continue to develop continuously in the future.

JSEDM

JSEDM is a globally recognized brand for its expertise in the manufacture of electric spark machining machines. With nearly 40 years of development, JSEDM offers many product lines: Wire EDM cutting machine, CNC pulse machine, ZNC pulse machine, EDM drilling machine, .. In order to meet the requirements of customers.

Factory producing brand JSEDM

MITSUBISHI

Mitsubishi Electric is a world leader in the production and sales of household, commercial and industrial electronics. With prestige and high quality, the brand’s products are always trusted and used all over the world.

MITSUBISHI Electronics Corporation

Industrial automation equipment is the main product group of MITSUBISHI group

HYPERTHERM

Hypertherm from the US was established in 1968 with more than 1,300 branches worldwide. Considered as a leading brand specializing in supplying welding sources, plasma cutting systems, consumable parts, etc. Serving for heavy manufacturing industries such as automobile manufacturing and repair, shipbuilding industry, construction …

High-end mechanical brand Hypertherm

Hypertherm welding source is highly appreciated by experts for its outstanding performance and fuel economy

In Vietnam market, positioning Weldcom as the leading prestigious company in the field of providing mechanical processing equipment and solutions, Hypertherm wishes to accompany Weldcom, bringing modern mechanical products, possessing high technology, user-friendly, contributing to promoting and improving the quality of products processed and manufactured in Vietnam.

The HyperthermHPR800 XD Plasma cutting source is being exclusively distributed by Weldcom in Vietnam

Not only a partner, Weldcom is also a bridge, searching and connecting leading manufacturers in the world such as Hypertherm with customers, joining hands to shorten the gap between Vietnamese mechanics and the global mechanical industry. .

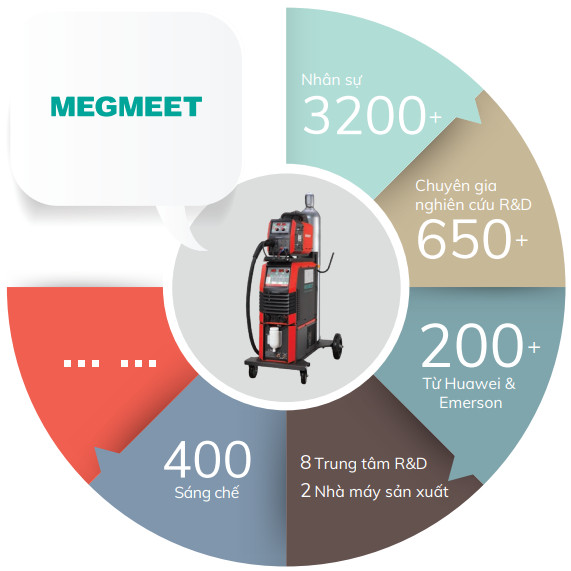

MEGMEET

Established in 2003, Shenzhen Megmeet Electric Co., Ltd. is a national high-tech enterprise with core technologies of power conversion, electrical control and software development in system communication and control. Megmeet’s main business is the development, production, sales and service provision of hardware, software as well as system solutions in the auto industry.

Smart welding machine brand Megmeet

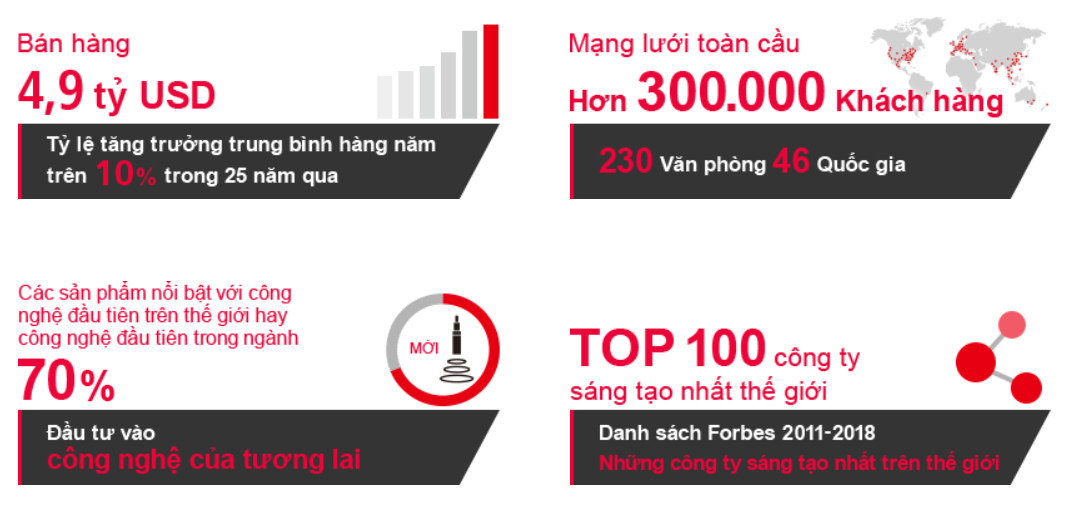

Impressive numbers from the brand Megmeet

Megmeet’s products are applied in many different industries

JASIC

Jasic is a global brand in the field of research and production of welding machines, plasma cutting machines and automatic welding equipment.

Brand of electronic welding machine, plasma cutting machine Jasic

- All Jasic rod welding machines are applied by the company with the latest IGBT inverter technology, which effectively saves the welding machine’s power during use.

- Good quality, durable, many customers appreciate and give good feedback.

- The design of the product is compact, sturdy, convenient for users to carry when moving.

- Jasic cutting machines and welding machines do not require too much technical skill for the machine operator. The cutting operations are also very simple and user-friendly. There is also no need to adjust too much when performing the operation.

Thanks to the advantage of advanced production technology, strong distribution ability of the brand’s products, in 2007, Jasic registered for trademark protection in 27 countries in Europe. In 2015, Jasic became China’s leading welding equipment manufacturer and is currently present in more than 80 countries globally.

The design of the Jasic welding machine is compact, solid, and convenient for users

In terms of professional capacity, Jasic owns 6 R&D centers located in China, USA, Italy and a team of nearly 200 experts with advanced equipment, Jasic also perfects a set of standards and quality inspection processes including includes more than 300 tests such as: EMC, weld quality, metal dust resistance, vibration resistance, impact resistance, operation in harsh weather conditions or continuous operation.

Plasma Cutting Machine Jasic

Weldcom is the exclusive distributor of Jasic products nationwide from July 1, 2011

Owning many showrooms in Hanoi, Hai Phong, Ha Nam, Da Nang, Ho Chi Minh City, Binh Duong… and a system of more than 1,300 agents nationwide, Weldcom has helped Jasic products reach many customers and quickly became a reliable arm of the mechanical loving community.

AGMA

Taiwan high speed CNC milling machine – Agma HPA-AM 1000

Factory Agma

AGMA’s BA-8 CNC machine is being distributed by Weldcom

In order to bridge the technology gap between the world and Vietnam, Weldcom has become a strategic partner of AGMA to distribute CNC milling machine products. With a system of showroom branches and more than 1300 agents nationwide, Weldcom is confident to bring customers the best AGMA products with the most advanced service, worthy of the money that customers spend to invest.

KRUMAN

Kruman is an international brand of machine tools, focusing on design, research, development and production of product lines: Cutting machines, bending machines, folding machines, rolling machines, multi-function punching machines, stamping machines. and some other specialized equipment.

Kruman CHS 6016 hydraulic corrugated iron cutting machine – CNC for Weldcom customers

Kruman hydraulic corrugated iron cutting line system and CLS Series

With the goal of bringing modern equipment and technologies to Vietnam, Weldcom cooperates with Kruman to become a strategic partner in distribution of cutting machines, presses, round cutters, square cutters .. At the same time, Weldcom always strives to accompany mechanical enterprises, is a solid bridge to make the Kruman brand become an important partner of many large manufacturing industry companies across the country.

HUAWEI

ShangHai Huawei & Cutting Machine Co.,Ltd was established in 1991, is currently the leading famous brand in China by its strength specializing in manufacturing welding machines, cutting machines, angle grinders, pipe cutting machines. , thermos,…

Brand of Huawei cutting machine

WORX

WORX is a brand of hand-held power tools manufactured by POSITEC – a multinational corporation specializing in research, production and distribution of power tool products with many high-end brands. Products from POSITEC are always applied the most modern technology and meet European standards.

Worx Power tools

Worx products always ensure the criteria set forth by the brand

- Worx green is used for industries that require constant work intensity and high quality. Green worx product lines receive very good reviews from customers thanks to their large operating capacity, effective anti-vibration, and no fatigue for users.

20V Li-ion battery powered drill WU189.2

- Worx orange is a specialized line for families and workers who are often on the move. Worx cam products possess a compact design, integrated with multi-functions to help users easily manipulate the machine without much effort as well as save working time.

20V Worx WX176 . universal battery screwdriver

ISI

ISI-GF Equipment (Wuhan) Co., Ltd. was established in July 2007, is a professional welding equipment manufacturer, focusing on welding machine R&D, design, production and service. The brand’s technology is derived from GF Welding, Italy, which has more than 60 years of R&D history in welding equipment.

ISI mechanical brand headquarters is located in Wuhan, China

ISI Manufacture welding cabinet controller

SIGMANEST

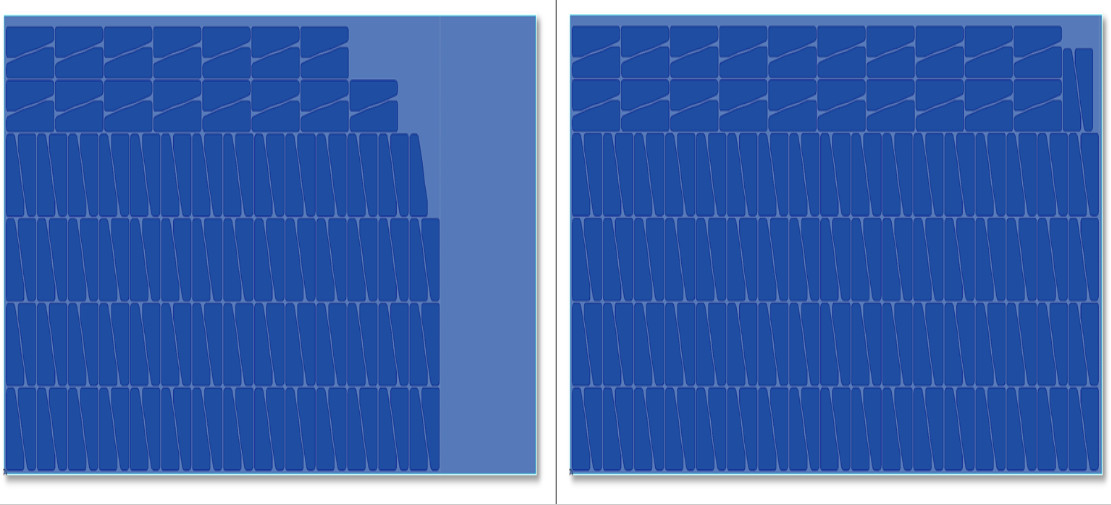

Sigmanest Powerpack software is a solution package from SigmaTEK Systems – A leading global provider of advanced CAD/CAM software solutions that help professional manufacturers increase profits by optimizing material usage. , machine movement, manpower and data management.

Sigmanest Powerpack software

- Material: The software increases productivity and saves materials by 2-4% compared to conventional ones.

- Motion (Optimized CNC cutting machine movement): The cutting machine applies software for faster cutting, shortening production time by 20%.

The software saves material 2-4% more than conventional

- Manpower: Reduce manpower, time on sorting, mixing, cutting on average 2 times faster.

- Manage: Sigmanest integrates data, detailed operating information of machines and areas.

- Machines: Create convenience and flexibility by operating multiple machines using only one software.

- Automatically convert from drawings to arrangement details.

- Select the appropriate corrugated board for optimal arrangement of multi-head cutters on a wide range of materials.

- Anti-stack Pump drag-and-drop properties for easy use.

- Features cut bridge (bridge), cut chain (chain), share road (common cut).

Common cut feature when using Sigmanest software

- Feature to avoid collision of torch and cutting product.

- Keep track of remaining cut sheet material and inventory.

- Automatically classify jobs by type, material thickness.

- Multiple sheets of material are displayed on the screen and can be manually moved over multiple sheets of material.

- iPierce primer hole sharing feature.

- Pre-piercing pre-piercing feature.

In Vietnam, Weldcom is the only owner authorized by Sigmateck to distribute and support Sigmanest. When becoming a partner of Sigmateck, Weldcom has distributed products to many large-scale enterprises such as Huy Thanh Mechanical and Metallurgical Company Limited, Thanh Tien commercial production company, Dai Dung steel structure corporation…

With a system of more than 1,300 agents and branches nationwide, Weldcom hopes to be a bridge to closely link Sigmanest products to Vietnamese businesses in the future.

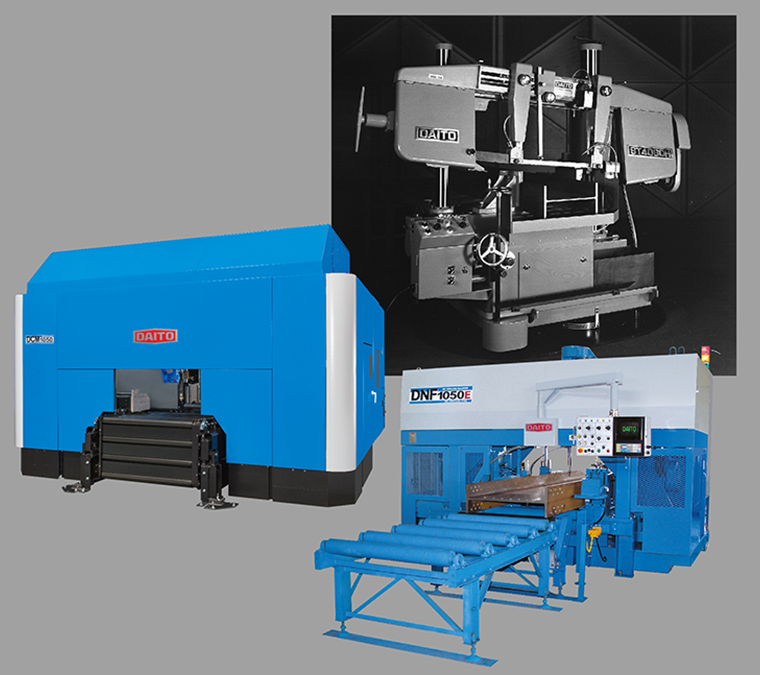

DAITO

Daito Seiki was founded in 1959 in Amagasaki City, Hyogo Prefecture, as a company that designs, manufactures and sells steel processing machines. At a time when Japan was struggling to rebuild after the war and with the desire to build a new society using entirely steel materials, Daito developed and launched a circular saw for steel materials. Since then, Daito has made an important contribution to improving people’s lives through steel processing machines.

Daito Seiki Precision Machining Machine Factory

Punching machines, sawing machines are Daito’s main products distributed in the world

FRONIUS

Fronius stands for new technology, in-depth research and revolutionary solutions. Founded in 1945, with a tireless creative spirit and a deep sense of quality, Fronius has always been a driving brand in welding, photovoltaic and battery charging technology and setting trends. market change.

A headquarters of mechanical brand Fronius in Germany

Fronius products are environmentally friendly and solve society’s problems

ABB

ABB is a Swiss-Swedish multinational corporation, headquartered in Zurich, Switzerland. Founded in 1883, the company operates mainly in the field of smart homes, manufacturing robots and automatic technologies…

Robot brand ABB

ABB robot meets many key industries in Vietnam

A pioneer in the field of automation, Weldcom is currently a major distributor and partner of ABB in Vietnam and one of the prestigious contractors using ABB automation robots in electric vehicle production lines. by Vinfast. Weldcom always strives to become a solid bridge to bring the ABB brand into an important partner of large enterprises across the country.

Vinfast electric vehicle factory

ABB robot distributed by Weldcom to Vinfast

TONGTAI

Tongtai, one of the leading brands of TTGroup, provides customers with complete machines, total solutions for different industries and attentive service around the world with branches. Established in 1969 in Kaohsiung, Taiwan and became a listed company in 2003, the brand started with machinery manufacturing and today, Tongtai is one of the leading machinery manufacturing companies. with the largest scale in Taiwan.

TongtaiGroup is headquartered in Kaohsiung Taiwan

Tongtai’s products have modern and beautiful designs

Tongtai EZ Series hole punch CNC milling machine is being distributed by Weldcom in Vietnam

In Vietnam, Tongtai has trusted to cooperate with Weldcom to become the official distributor of milling machines, lathes, etc. At the same time, authorized to provide “turn-key projects”, Weldcom is confident to bring to customers. Vietnamese mechanical enterprises with international quality products and excellent services.

RAYCUS

Raycus is a leading developer and manufacturer in China of fiber lasers. It is the first Chinese enterprise engaged in the research, development and large-scale production of high-power fiber laser sources. The company’s main business includes providing fiber laser products and application solutions to laser manufacturing equipment integrators and providing customers with technology research and development services. and customized products.

Raycus brand factory

Raycus welding source is integrated on the Weldcom LW1000M . laser welding machine

Weldcom is the exclusive distributor of Raycus welding source in Vietnam market

With the advantage of product quality and service, maintenance, replacement, repair and replacement of genuine parts, buyers can be completely assured when investing in welding machines. laser supplied by Weldcom .

KEYENCE

KEYENCE has grown steadily since 1974 to become an innovative leader in the development and manufacture of industrial automation equipment and testing equipment worldwide.

Keyence industrial automation equipment manufacturing brand

Keyence products are distributed around the world

Today, KEYENCE has grown into a global leader in the industrial automation industry. KEYENCE has rapidly expanded to 230 offices located in 46 countries and serves more than 300,000 customers residing in 110 countries.

Impressive numbers from Keyence brand

DTM

JINFENG

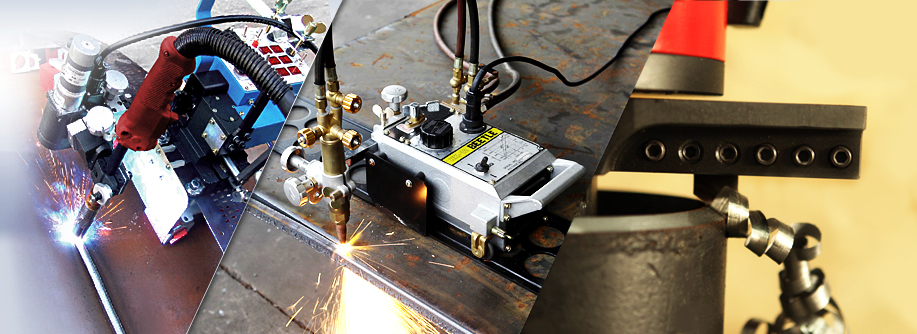

Ningbo Jinfeng was established in 2001, is a modern enterprise specializing in the design and manufacture of NC cutting machines and welding equipment. In China, the company is one of the largest manufacturers of gas cutters and nozzles.

Jinfeng brand is based in Ningbo, China

Jinfeng factory owns many advanced modern technology

QJAR

QJAR Robotics is a prominent Chinese robot brand from Zhejiang Qianjang Robot Company – a pioneer in the production of domestic industrial robots and has expanded many customer segments in the market. The brand constantly focuses on designing industrial robots and core equipment according to ISO9001 and CE standards from SGS, in order to provide the highest quality products and services to businesses around the globe.

High-tech robot brand Qjar

- QJAR’s welding robots have the ability to handle and operate very quickly and flexibly by integrating the product with its own controller and the bottom layer is IPC, helping the robot to have a processing speed 100 times faster than the Chinese brand. Other country.

Qjar robot has fast processing speed and flexibility

- The robot’s motor, reducer and transmission parts are used by QJAR from famous Japanese and Chinese brands such as Tamagawa and Nabtesco, Shimpo, Shuanghuan.

- QJAR used the best equipment in the world to cast the robot, making the robot’s actual performance stable, unaffected by surrounding devices.

- To ship, QJAR robots must be rigorously tested, continuously for 108 hours to bring the best products to the market.

TYPICAL CUSTOMERS

HOA PHAT GROUP

Hoa Phat is a leading industrial production group in Vietnam. Established in 1992, the group started from a company specializing in trading construction machines, then expanded to other fields, in order to turn the business into an industrial production group with high quality. leading, in which Steel is the core field.

Hoa Phat Group

Hoa Phat Group is holding the No. 1 market share in Vietnam for construction steel, steel pipes and Australian beef. HPG’s market capitalization reached 11 billion USD, among the top 15 steel companies with the largest market capitalization in the world steel industry.

Currently, Hoa Phat Group operates in 05 fields: Iron and Steel – Steel Products – Agriculture – Real Estate – Appliances. In which, steel production is the core field, accounting for 90% of the group’s revenue and profit. With a capacity of 8 million tons of crude steel per year, reaching a revenue of VND 150,800 billion (in 2021), the total field has made Hoa Phat the largest steel producer in Southeast Asia.

Hoa Phat Group owns a large steel factory

With the spirit of creativity and continuous improvement in technology, Hoa Phat Group has continuously won awards such as: Top 500 largest enterprises in Vietnam, Strong Brand in Vietnam from 2007 to present, Top 50 Vietnamese enterprises. Outstanding Male in 2021, Top 10 Entrepreneurs With the business philosophy of “Harmony for Development”, Hoa Phat spends a budget of hundreds of billions of dong per year to fulfill its corporate social responsibility to the community.

With the enthusiasm to lead by quality, Hoa Phat Group has always invested and applied the most advanced technologies and solutions to save energy and protect the environment in its production and business activities, ensuring ensure to provide the market with quality products with sustainable value.

Besides, Hoa Phat also focuses on modern production machinery system to meet the needs of the market. The unit chosen by Hoa Phat to send gold to become the main mechanical equipment distribution partner is Weldcom and hopefully, Hoa Phat and Weldcom will always be companions on the development path to bring quality products to customers across the country.

PCC-1

Construction Corporation 1 – Petrolimex (PCC-1 Group), formerly known as Construction Company I – Basic Construction Department – Ministry of Materials, was established on March 17, 1969. With a tradition and experience of more than 50 years, is Vietnam’s leading enterprise in the field of construction and installation specialized in petroleum, Jet A-1, chemicals, petrochemicals, lubricants, asphalt, petroleum, gas & liquefied gas…

Logo of Petrolimex 1 Construction Group Joint Stock Company

With more than 50 years of construction and development, the Company has constructed and put into use millions of m3 of petroleum storage tanks, tens of thousands of kilometers of oil pipelines and many projects of Jet A-1 storage, chemicals, and chemicals. oil, lubricants, asphalt, petroleum, gas & liquefied petroleum gas, petrol stations, industrial and civil works… Serving thousands of large and small projects inside and outside the industry throughout the territory of Vietnam and Laos and Cambodia, are highly appreciated and trusted by customers.

Up to now, PCC-1 Group is a partner with many investors and project developers such as: Vietnam National Petroleum Group and its member companies, Vinapco (Skypec), Nghi Son Refinery and Petrochemical Plant, JGC Japan, Toyo (Thailand), Wec (Singapore), Chitchareune (Laos), Sokimec (Cambodia), Adeo Asphalt (France), Can Tho PV Oil, PVN, Military Petrochemicals, Thien Minh Group Joint Stock Company Germany, ICT Company, Duc Giang Chemical, Vam Co Chemical, Hai Ha Chemical..

PCC-1 owns modern and advanced equipment

With contributions to the development of the country, PCC-1 Group was honored to be awarded noble awards by the State such as: Third-class Independence Medal in 2008, second-class in 201, certificate of assessment and implementation. comply with the requirements of the ISO 9001-2015 Standard; In 2017 and 2018: PCC-1 Group was honored to be certified as Top 500 Largest Private Enterprises in Vietnam and Top 50 Top Brands in Vietnam.

In the process of integration and development with increasing requirements for quality, progress and safety of works, PCC-1 Group has invested in modern equipment, trained human resources in depth. serving the construction and installation of four-tank warehouses, technological pipelines…. Therefore, PCC-1 has trusted and chosen Weldcom as a partner in the distribution of mechanical equipment towards the success of the project. Sustainable development for businesses.

ANH DONG Metal CNC

Located in Tan Binh Industrial Park, Tay Thach Ward, Tan Phu District, Ho Chi Minh City, ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED is known as a prestigious enterprise specializing in sheet metal processing, especially for the elevator industry. and interior decoration with more than 20 years of experience.

Starting from a small private production facility that started operating from 1997-1998, Anh Dong has made continuous efforts to assert its name and become one of the leading manufacturers of household products. Elevator construction, leading interior decoration in Ho Chi Minh City.

ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED

With his knowledge and enthusiasm, Mr. Phan Anh Tuan – Director of Anh Dong Production, Trade and Service Co., Ltd. has diligently researched and selected to invest and gradually replace old machines with new technologies. advanced technology to best meet the needs of high-quality mechanical processing of customers.

Anh Dong has trusted Weldcom to be the distributor of laser cutting machines, Yawei presses, CNC punching machines, etc. In the period from 2018 to 2021. Up to now, Anh Dong has owned a metal processing production line. $1 million worth of state-of-the-art panels capable of rapidly delivering orders of the highest quality. This has been confirmed through the success of a series of projects that Anh Dong participates in to provide products such as mixed-use buildings, office buildings, hotels, apartments to small and medium projects such as hospitals. Hospitals, family houses, factories, schools…

Anh Dong owns a modern processing production line provided by Weldcom

Anh Dong’s revenue in recent years has continuously grown at an average rate of about 50%. Right before the pandemic, the company’s revenue from mechanical processing services alone reached more than 30 billion dong.

Going up by strength and taking the prestige of product and service quality as a goal for more than 20 years, ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED is a typical example for a private enterprise. bravery, dynamism and will surely make further strides in the sheet metal processing industry.

ATAD

ATAD is one of the typical enterprises that provide customers with a package solution including the stages of consulting, design, production, and erection of high-quality pre-engineered steel buildings and steel structures.

Since its establishment in 2004, ATAD has performed more than 3,500 projects in more than 40 countries and territories with a network of representative offices in: Myanmar, Indonesia, Thailand, Philippines, Cambodia, Sri Lanka, Bangladesh and Uganda.

ATAD currently owns more than 2200 professionally trained employees, quality management system ISO 9001: 2015; ISO 14001:2015, ISO 45001:2018 and 2 modern manufacturing plants with a total area of 211,000 m2. These two factories are one of the largest and most modern steel structure production lines in the world. Especially, ATAD Dong Nai factory, Vietnam is the first steel structure factory in Asia to achieve LEED Gold standard and the first factory office in Vietnam to achieve LEED Platinum.

ATAD’s factories have comprehensive manufacturing capabilities from the largest steel components to the smallest parts, the most complex parts to the simplest components, oversized or oversized components or Special steel structure, difficult to manufacture. To do that, ATAD cooperated with Weldcom to select products for the production of steel structures.

Some typical projects of ATAD at home and abroad: Vinfast automobile production complex, Hoa Phat – Dung Quat steel production complex, Cam Ranh international airport passenger terminal, international airport passenger terminal Da Nang International Airport, Passenger Terminal of Wattay International Airport (Vientiane, Laos), Vinh Tan 4 Thermal Power Plant Expansion…

One of the core values of ATAD Steel Structure Joint Stock Company is to constantly innovate and create to provide the best quality products and services. It is this strong effort that has helped ATAD win recognition and prestigious awards and certifications such as: Top 50 excellent enterprises, Vietnam gold star award in 2021, Engineering firm of the year 2021…

With the above efforts, ATAD is determined to become a well-known brand that is proven in the construction industry and a leading steel structure company in providing solutions for pre-engineered steel buildings and steel structures. the most effective.

MINH VIET SON Corporation

The Mechanic – Colsultant – Construction – Service Minh Viet Son Corporation was established in 1992, operating mainly in the field of civil and industrial construction: Design, Production and erection of steel buildings. Prefabricated and high quality steel structure in Vietnam – General contractor for designing and building industrial plants, installing machinery and equipment and supporting services such as Canteen, garage, security house, office …

The Mechanic – Colsultant – Construction – Service Minh Viet Son Corporation

MVS owns a factory system with an area of 8000 m2 located in Binh Duong, with a production capacity of up to 6000 tons/year, of which 500 tons of steel structures/month. Besides, Minh Viet Son also owns a complete and modern machinery line, and a staff of more than 120 professionally trained employees, meeting solutions for pre-engineered steel buildings, structural components. quality steel structures to customers quickly and efficiently.

Minh Viet Son also obtained ISO 9001: 2015 certification in the field of Design, construction of civil and industrial constructions, steel structure erection. With a high quality management system, Minh Viet Son believes in providing the best solutions, high quality products and the most perfect service for the project to customers.

Minh Viet Son factory is located in Thuan An, Binh Duong

Some typical successful projects of Minh Viet Son can be mentioned such as Livax Vietnam Factory, SST Vietnam, SML Vietnam Expanded Factory, Bandai Vietnam Factory, Logitem Vietnam Logistics Center (Tan Dong). Hiep)…

In order for the products to achieve quality and bring success, Minh Viet Son’s machine line system is a top priority. Minh Viet Son has trusted Weldcom – a leading unit specializing in providing mechanical and structural steel processing solutions nationwide.

Bruco GBH4000 – S3 smart gate welding machine distributed by Weldcom

Weldcom is pleased to be a reputable supplier accompanying Minh Viet Son with steel structure production equipment such as Horizontal Welding Gate, CNC punching machine, steel beam attachment machine… Together, we hope to bring the best products. for customers.

AMECC JSC

Formerly LISEMCO 2 Joint Stock Company, renamed AMECC Mechanical Construction Joint Stock Company since 2016, with goodwill to cooperate for mutual development, jointly bring the best values to customers through through the products and services that AMECC is currently providing such as: Processing and manufacturing steel structures and equipment, hot-dip galvanized products, construction and installation of project items, general contractor/EPC contractor civil and industrial projects.

Factory and headquarters of AMECC Mechanical Construction Joint Stock Company

Currently, the enterprise has 2 factories manufacturing equipment and steel structures with a total area of 210,000m2, and the processing capacity is about 30,000 tons/year. Along with a team of experienced and highly specialized personnel combined with modern production lines and equipment systems operating according to ISO standards, we are committed to providing products and services that meet ISO standards. good quality criteria, ahead of schedule.

“SAFETY – QUALITY – PROGRESS – EFFICIENCY” is the motto that helps AMECC to launch mechanical products with good quality, meeting all the most stringent requirements of customers. AMECC has brought products and services to a number of typical customers such as Samsung, BHI, Hyundai, Sankyu, Marubeni, Kirchner, EVN, PVN, etc.

Yawei Laser Cutting Machine supplied by Weldcom to AMECC

To achieve today’s successes, AMECC has constantly innovated technology, modern equipment for construction, invested in the most advanced production lines, meeting all the most demanding needs of the owner. private works. In the market, AMECC has trusted and cooperated with Weldcom – the distributor of mechanical equipment to serve its production.

INTECH GROUP

Vietnam Industry and Technology Group Joint Stock Company (INTECH GROUP) is a leading unit in Vietnam providing conveyors, conveyor belts, rollers, roller conveyors, intelligent conveyor systems, and systems. Advanced, cost-effective industrial automation systems and solutions, Intech’s products are standardized through years of research and development, products are thoroughly tested from processing to manufacturing. to assemble and test run.

Vietnam Industry and Technology Group

With a factory area of up to 4000m2, a more professional staff of up to 110 people, and good production capacity with complete and modern machines, Intech is a destination, as well as a trusted partner. reliable for many companies, large corporations at home and abroad.

Products of Intech Vietnam have applied the quality management system of ISO 9001:2015, which helps products and Intech Vietnam affirm its position in the domestic and export markets for the field. industrial rollers and conveyors, helping the brand conquer the world’s top fastidious markets such as Japan, Hong Kong, and Mexico.

In order for products to meet quality standards, Intech Vietnam has selected units to invest in modern machinery and technology systems to achieve the above criteria. Weldcom is a leading supplier of mechanical equipment for presses, Yawei punching machines… Along with solutions in the field of mechanical engineering in Vietnam.

Yawei press machine PBH220 distributed by Weldcom

Weldcom is one of the few suppliers that owns the strongest distribution channel today with more than 1300 agents and showroom branch system covering the whole country, Weldcom always strives to become a solid bridge, bringing new high-quality products for the Vietnamese mechanical business community.

GSB Steel

GSB Steel Structure Joint Stock Company, precursor from Trac Viet Phat Co., Ltd., was first established on July 7, 2011, After 9 years of establishment and development with the premise of experience in mechanical engineering. now make the determination to go deep into the field of steel structure.

Logo of GSB . Steel Structure Joint Stock Company

GSB . steel structure factory

Besides, GSB also focuses on investing in modern machinery and equipment to ensure output quality to meet the strict demands of the market. AMECC has trusted and wished to cooperate with Weldcom, the leading prestigious unit in the field of providing mechanical processing equipment and solutions, contributing to promoting and improving the quality of products, helping to elevate its position. of GSB is the leading steel structure brand in Vietnam.

Weldcom supplies Bruco BMC – 4000 plasma CNC laser cutting machine for GSB

With the enthusiastic support of partner companies, big investors, GSB Steel Structure Joint Stock Company has been and is constantly striving to improve in terms of organization, with high responsibility in the work of bringing the Customer interests come first.

NGAI CAU JSC

NGAI CAU BUILDING AND COMMERCIAL INVESTMENT JOINT STOCK COMPANY was established in 2004 from the predecessor as a mechanical workshop operating since 2001. The enterprise is currently a unit specializing in mechanical processing and hot-dip galvanizing of steel columns. Model for electricity industry, television poles, telecommunications.. Steel beams, collars, bolts, grounding… For transmission lines, substations Bolt anchors from M16, M24, M27, M36, M90, Transformer support Voltage and equipment for stations from 110- 220-500KV, Pre-engineered steel buildings…

Logo of NGAI CAU BUILDING AND COMMERCIAL INVESTMENT JOINT STOCK COMPANY

In particular, the company’s main business is “Manufacturing and supplying structural steel products for construction engineering, electricity, telecommunications and transportation”. In addition, Ngai Cau’s products are strictly controlled from production to release to the market and are managed according to ISO 9001: 2015.

The products manufactured by Ngai Cau always ensure quality, technical requirements, art and progress, so they are highly appreciated by investors and construction contractors. To achieve the above quality standards, Ngai Cau went to Weldcom to choose the best equipment and solutions in the mechanical processing industry for businesses.

Factory of Ngai Cau company

CPT STEEL

CPT STEEL with nearly 20 years of establishment and development is a professional contractor in the field of steel structures for factories, warehouses, restaurants and works related to pre-engineered steel buildings, performed in each stage “CONSULTATION” DESIGN – PRODUCTION – INSTALLATION”.

CPT STEEL

Currently, CPT STEEL has 3 factories with a total area of 7 hectares. The total output of 3 modern 4.0 technology factories, with a capacity of up to 4,000 tons/month, applies a quality management system according to ISO 9001:2015. With a team of nearly 400 experienced and highly qualified employees, who are trained regularly and methodically. When implementing CPT projects, STEEL always maintains and strictly implements the criteria “SAFETY – QUALITY – PROGRESS – OPTIMAL SOLUTION – COMPETITIVE PRICE”. Therefore, it has satisfied all the most demanding investors such as: Japan, Korea, Taiwan, Malaysia, Singapore, Hong Kong, Czech Republic, Vietnam,…

CPT STEEL Factory

GBH4000 S3 smart gantry welding machine supplied by Weldcom for CPT STEEL

CPT STEEL’s steel structure processing line system has been supplied, constructed and installed by Weldcom to help businesses meet the strict demands from the market. Mr. Le Viet Hieu – Director of CPT factory shared: “We are very satisfied with the installation progress and quality of services provided by Weldcom and especially appreciate the spirit and working attitude of Weldcom construction and installation staff”.

OMEGA

Omega Vietnam Steel Structure Joint Stock Company was established in 2017, operating in the following fields: Mechanical production – steel structure; construction, consulting and design of industrial and civil works using high quality steel structures.

Close-up of the outside of the Omega factory

CIENCO 4

CIENCO4 is proud to be one of the most prestigious enterprises in the construction industry in Vietnam and a prestigious partner of many domestic and international organizations such as ADB, Worldbank, Jica, Ministry of Transport… CIENCO4 is the contractor ranked highest by the Ministry of Transport in being the investor of infrastructure construction projects in the period 2012 – 2015.

Logo of CIENCO4 Group JSC

CIENCO4 is also one of the units with 50 years of experience in implementing many road and bridge projects, seaports and airport construction projects going through the historical and development stages of the country. .

CIENCO4’s ability to execute construction and installation packages has been confirmed when the enterprise is selected as a cooperation partner with large domestic and foreign corporations and companies to implement large projects such as the Factory Project. Yen Xa wastewater treatment, Le Van Luong tunnel construction project – Ring 3, renovating the intersection cluster west of Tran Thi Ly bridge…

Ben Thanh station project is implemented by Cienco4

From 2000 to 2010, the Group was continuously the leading unit in the emulation movement of the Transport Industry, was awarded many noble awards by the State and Government, in 2008 the Group was awarded the Ho Chi Minh Medal. Ho Chi Minh, the title of Hero of the People’s Armed Forces, the title of Hero of Labor, the Order of Ho Chi Minh…

After nearly 60 years of fighting, building and growing, the Group has constantly innovated its management organization and invested in technological equipment to improve product quality. CIENCO4 has trusted and cooperated with Weldcom – the leading unit in providing equipment and solutions in the mechanical processing industry in Vietnam market. Weldcom’s companionship is the premise for CIENCO4 to bring the best solutions to all customers nationwide.

VINFAST

VinFast is Vietnam’s first automobile brand under Vingroup, led by Mr. Pham Nhat Vuong. With a vision to become a global smart electric car company. VinFast has laid the foundation for the automobile and electric motorcycle manufacturing industry in Vietnam, and is making efforts to contribute to promoting the electric vehicle revolution around the world.

Vinfast factory complex in Hai Phong

From March 2018 to September 2018, Weldcom designed, supplied and installed complete equipment 21 robot welding stations, 25 ABB robots for Vinfast electric motorcycle frame welding workshop according to European standards for electric motorcycles. workspace, occupational safety and product quality.

HAI DANG JSC

PEB STEEL

PEB Steel is a subsidiary of PEB Group (Europe) and has been operating in Southeast Asia since 1994. Over 28 years of development, PEB Steel has built a solid reputation in the pre-engineered steel building industry. in Vietnam and many countries around the world.

PEB STEEL pre-engineered steel corporation

PEB STEEL’s pre-engineered steel factory is located in Vietnam

QSB STEEL

QSB Steel is an enterprise specializing in designing, manufacturing, providing customers with a package solution including the stages of consulting, designing, manufacturing, and erecting quality steel structure products and pre-engineered steel buildings. high in Vietnam. QSB Steel offers customers a variety of choices including: factories, warehouses, high-rise buildings, heavy industrial projects, commercial centers, exhibition centers, transportation infrastructure (stations, yards). fly…).

Factory of QSB STEEL

QSB STEEL’s Phung Nguyen garment factory project

Weldcom provides smart horizontal welding port HN0630- S1 for QSB STEEL

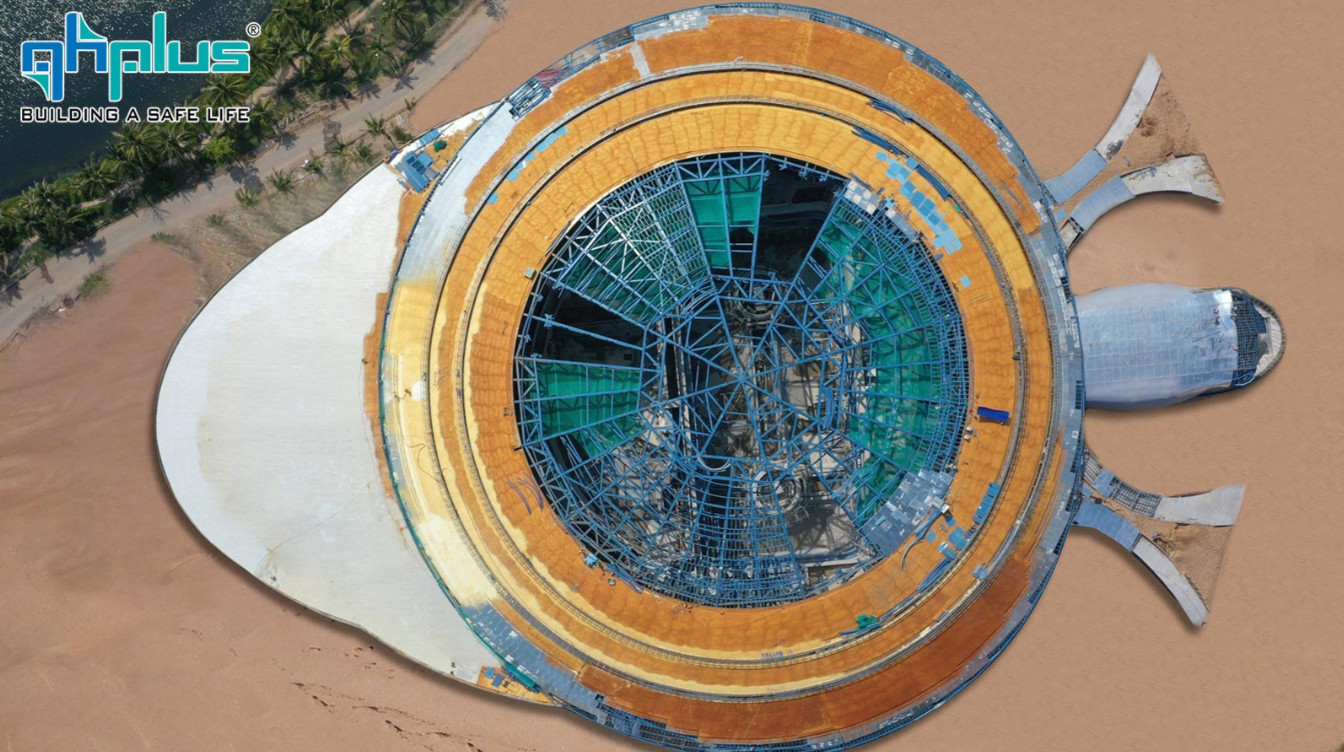

QHPLUS

QHPLUS Joint Stock Company, formerly known as Quang Hung Co., Ltd., was established in February 2006 with the main business product being rolled steel. Currently, the company has become a leading trader of steel structures, building materials, interior decoration and construction accessories in Vietnam and the region.

Construction steel plant of QHPLUS in Ba Ria – Vung Tau Province

Up to now, QHPLUS is a partner with many investors and developers of typical projects such as: Vincom Da Nang, HYOSUNG Vung Tau Petrochemical Plant, Vinpearl Golf Land Resort, HEINEKEN Factory, the project SEASHELLS Phu Quoc, Chau Duc Solar Power Plant… In 2020, the output that QHPLUS provides to domestic and international markets will reach 429,993 tons and reach a revenue of 5787 tons.

SEASHELLS Phu Quoc project

DONG ANH STEEL

Construction Steel Structure Joint Stock Company (COMESS) with the brand name Dong Anh Steel Structure – One of the enterprises with 25 years of experience in developing, pioneering in the field of design, production and erection of products. High quality steel structure products have become a reliable address of domestic and foreign investors.

COMESS steel structure factory in Dong Anh

Dong Anh STEEL factory owns many modern and advanced equipment

CHS6016 – CNC Kruman corrugated iron cutting machine supplied by Weldcom to Dong Anh Steel

THIEN TRUONG STEEL

Thien Truong Manufacturing and Trading Company Limited was established in July 2002, is a steel structure manufacturer providing services such as design, fabrication, finishing, processing, transportation and erection of steel structures and steel structures. Through more than 20 years of history and development, THIEN TRUONG’s completed projects and expertise are continuously enhanced to meet the needs of customers from many fields: Metallurgy, mining, hydropower, manufacturing, residential and commercial projects.

Thien Truong company factory

Thanks to its strong production capacity, the factory has a roof of 60,000 m2, equipped with the most modern and advanced synchronous machinery and equipment, allowing THIEN TRUONG to manufacture custom steel structures with sizes ranging from large to very large. Big comes with strict standards and deadlines. The current THIEN TRUONG factory not only serves customers in Vietnam but also is trusted by foreign customers for export orders. Customer satisfaction is the greatest reward for our unremitting dedication to service quality.

Weldcom supplies Yawei laser cutting machine to Thien Truong

Specifically, Mr. Tran Dinh Tan – Director of Thien Truong Company shared: “Currently, all machines in our factory are Jasic machines, along with most of the welding and cutting accessories provided by Weldcom. I am very satisfied with the quality of products and services of Weldcom. Thien Truong and Weldcom will always be companions on the way of business development.” The compliments from Thien Truong company are clear proofs. Highlights for the quality and service of Weldcom.

RANG DONG

Headquarters of RANG DONG

Yawei HLE 1KW laser cutting machine supplied by Weldcom to Rang Dong

But the above efforts helped Rang Dong achieve typical titles such as: Labor Hero, First-class Independence Medal in work; Victory Medal for maintaining political security in the period 1992 – 1996, Top 100 famous brands of ASEAN in 2020, Top 500 best growth enterprises in Vietnam… In 2017, Weldcom cooperated with Rang Dong to provide supplying Yawei HLE 1KW laser cutting machine to meet the production needs of enterprises.

THANH TIEN

- Provide high quality products, best service, fastest progress.

- Most competitive price.

- Satisfy the needs of our customers to the fullest extent.

THANH TIEN PRODUCTION COMMERCIAL COMPANY LIMITED

- Fireproof door, safety steel door, 60-minute, 120-minute, 180-minute fireproof steel door, industrial steel door, anti-radiation lead coated steel door.

- Producing cabinets containing fire fighting tools, cable tray ladders…

- Laser cutting, CNC bending, sheet metal processing.

Thanh Tien’s main products are currently contributing significantly to the application of new technologies in the construction field in general and the finishing field in particular. And the company’s success is recognized through a series of contracts and valuable projects with large domestic and foreign companies and enterprises, trusted and highly appreciated by customers.

Besides, Thanh Tien owns 3 factories with a total area of up to 17000m2, with professional staffs and modern machinery system imported directly from Germany, Japan, China. and is meeting all the standards of customers from the smallest details.

Thanh Tien’s Yawei press system is provided by Weldcom

HUY THANH STEEL

Huy Thanh was officially established on February 19, 2004 with the starting point of development in the traditional craft village of Phung Xa specializing in agricultural production. tool.

Công ty TNHH Cơ Khí Kim Thành

- Pre-engineered steel building frame.

- Space floors, steel pillars, cyclones, stamping, bending, folding U – C – Z products.

- Manufacturing, welding electrical cabinets, cutting troughs for processing steel – stainless steel, cutting metal patterns and cutting ciphertexts with laser technology…

The first Yawei 15KW laser cutting machine with the largest capacity in Vietnam provided by Weldcom

DAI DUNG CORP

Established in 1995, now Dai Dung is one of the leading enterprises in Vietnam in the field of pre-engineered steel buildings, high-tech steel structure production to serve key national key industries such as: oil and gas rigs, thermal power plants, petrochemical refineries, industrial buildings, high-rise buildings, etc. From simple to complex; with standard and non-standard product lines, super-long and super-weight.

With a vision to become a steel structure manufacturing corporation, sustainable development bearing the mark of a national brand worthy of international standards, Dai Dung is gradually asserting and reaching out to be one of the EPC contractors in the industry. heavy industry and civil construction.

DAI DUNG METALLIC MANUFACTURE CONSTRUCTION AND TRADE CORPORATION

Over 25 years of establishment and development, with strength in the field of design, production and construction, Dai Dung is proud to be a prestigious construction contractor for many businesses such as Long Phu Quy Nhon Thermal Power Plant. 60,000 tons in Soc Trang; Japan Nippon Thermal Power Plant; Linkou Talin thermal power plant with 20,000 tons in Taiwan, Nghi Son oil refinery in Thanh Hoa, Masan Nghe An factory with a scale of 150 thousand square meters, Lotte Long An cold storage…

Yawei HLG laser cutting machine distributed by Weldcom to Dai Dung

Weldcom is one of the few suppliers that owns the strongest distribution channel today with more than 1300 agents and showroom branch system covering the whole country, Weldcom always strives to become a solid bridge, bringing new high-quality products for the Vietnamese mechanical business community.

SBC – SEICO GROUPS

SEICO (Steel Frame House and Industrial Equipment Joint Stock Company) was established in 2003 with a wave of investment from Japan and other industrialized countries. An enterprise specializing in the field of design, manufacture and construction of steel structures, steel buildings for many industries, civil, traffic, and commerce nationwide. Through the process of formation and development, so far SEICO has become a reliable partner of many construction enterprises and large domestic and international investors.

SEICO currently owns 04 factories equipped with world leading technology, annually supplying to the market more than 60,000 tons of steel structures and 02 million square meters of roof panels, wall panels, millions of square meters of floor panels and Truss Deck reinforced floor slabs and nearly 30 million liters of paint of all kinds.

SEICO,.JSC

Seico has been constantly searching and choosing to invest in modern machinery and equipment for the field of steel structure. In September 2020, Weldcom supplied the Yawei HLF 220 laser cutting machine with a capacity of 15 kw to Seico in Hai Duong so that the company’s products always achieve the best quality.

STRATEGIC PARTNERSHIP

HURCO

In the field of machine tool manufacturing, there are many companies and corporations that stand out as “big boss” that are hard to replace. One of them is Hurco – America’s Top 1 manufacturer of machine and tool equipment, highly appreciated and well received by the mechanical world. The following article will help readers better understand this famous brand.

Thương hiệu HURCO

HURCO is a corporation specializing in manufacturing machines and industrial equipment for the precision mechanical field, established in 1968 and headquartered in Indianapolis, USA. According to Technavio’s 2020 market research report, Hurco ranks 4th in the list of leading precision machining machine manufacturers in the world, behind DMG Mori, Yamazaki Mazak and Okuma.

Currently, Hurco owns 3 manufacturing plants located in 3 countries, USA, Italy and Taiwan. The Group has merged two more brands Takumi, Miltronics and established 12 representative offices spread worldwide a full range of experienced human resources ready to provide before- during- after- sales service.

In the range of equipment in the field of precision mechanics, Hurco mainly focuses on two lines of CNC milling machines and CNC lathes for stability and high accuracy, suitable for enterprises producing auxiliary industries, metal processing, stonework, mold making to applications requiring high precision such as aeronautics – space, defense, etc

Product made by Hurco CNC lathe with high precision

Hurco is also a technology master when it always tries to research and improve to integrate modern technology into each product to improve performance through WinMax controller. This part has a compact design but possesses many outstanding features that allow users to flexibly select modes suitable for the purpose of processing finished products. As a result, businesses can thoroughly solve backlog problems in production, towards creating products faster, saving machining time up to 30% and optimizing work for people.

Over the years, the Hurco corporation’s machine tool products have been present and have been chosen by consumers in the most demanding markets such as the US, Canada, Korea, Europe, etc. European region – where the standards for mechanical equipment products are judged to be strict. In addition, Hurco has also been named “Top Brand” and “Excellent Supplier” by prestigious industry organizations, such as Advanced Manufacturing Research Center (AMRC), American Machinist Magazine and Gardner Business Media. Its global sales reached $227 million (54% of sales in Europe); supplying equipment to many major partners such as Airbus, Honeywell, Caterpillar, Nasa, John Deere, Weldcom, etc. The above achievements are the clearest evidence for Hurco’s continuous development efforts.

In 2022, Weldcom has become the official authorized and warranty partner of Hurco in Vietnam market. The cooperation of the two brands will be a premise for domestic enterprises to approach and update advanced equipment and machines in order to improve technology, improve production capacity, increase competitive advantages and increase competitiveness. supporting the strong development of the current domestic precision mechanical industry.

Weldcom is the official authorized and warranty partner of Hurco in Vietnam

For more information about Hurco products, please contact Weldcom at Hotline: 19009410 or leave your information in the comment section below.

HOA PHAT GROUP

Hoa Phat is a leading industrial production group in Vietnam. Established in 1992, the group started from a company specializing in trading construction machines, then expanded to other fields, in order to turn the business into an industrial production group with high quality. leading, in which Steel is the core field.

Hoa Phat Group

Hoa Phat Group is holding the No. 1 market share in Vietnam for construction steel, steel pipes and Australian beef. HPG’s market capitalization reached 11 billion USD, among the top 15 steel companies with the largest market capitalization in the world steel industry.

Currently, Hoa Phat Group operates in 05 fields: Iron and Steel – Steel Products – Agriculture – Real Estate – Appliances. In which, steel production is the core field, accounting for 90% of the group’s revenue and profit. With a capacity of 8 million tons of crude steel per year, reaching a revenue of VND 150,800 billion (in 2021), the total field has made Hoa Phat the largest steel producer in Southeast Asia.

Hoa Phat Group owns a large steel factory

With the spirit of creativity and continuous improvement in technology, Hoa Phat Group has continuously won awards such as: Top 500 largest enterprises in Vietnam, Strong Brand in Vietnam from 2007 to present, Top 50 Vietnamese enterprises. Outstanding Male in 2021, Top 10 Entrepreneurs With the business philosophy of “Harmony for Development”, Hoa Phat spends a budget of hundreds of billions of dong per year to fulfill its corporate social responsibility to the community.

With the enthusiasm to lead by quality, Hoa Phat Group has always invested and applied the most advanced technologies and solutions to save energy and protect the environment in its production and business activities, ensuring ensure to provide the market with quality products with sustainable value.

Besides, Hoa Phat also focuses on modern production machinery system to meet the needs of the market. The unit chosen by Hoa Phat to send gold to become the main mechanical equipment distribution partner is Weldcom and hopefully, Hoa Phat and Weldcom will always be companions on the development path to bring quality products to customers across the country.

PCC-1

Construction Corporation 1 – Petrolimex (PCC-1 Group), formerly known as Construction Company I – Basic Construction Department – Ministry of Materials, was established on March 17, 1969. With a tradition and experience of more than 50 years, is Vietnam’s leading enterprise in the field of construction and installation specialized in petroleum, Jet A-1, chemicals, petrochemicals, lubricants, asphalt, petroleum, gas & liquefied gas…

Logo of Petrolimex 1 Construction Group Joint Stock Company

With more than 50 years of construction and development, the Company has constructed and put into use millions of m3 of petroleum storage tanks, tens of thousands of kilometers of oil pipelines and many projects of Jet A-1 storage, chemicals, and chemicals. oil, lubricants, asphalt, petroleum, gas & liquefied petroleum gas, petrol stations, industrial and civil works… Serving thousands of large and small projects inside and outside the industry throughout the territory of Vietnam and Laos and Cambodia, are highly appreciated and trusted by customers.

Up to now, PCC-1 Group is a partner with many investors and project developers such as: Vietnam National Petroleum Group and its member companies, Vinapco (Skypec), Nghi Son Refinery and Petrochemical Plant, JGC Japan, Toyo (Thailand), Wec (Singapore), Chitchareune (Laos), Sokimec (Cambodia), Adeo Asphalt (France), Can Tho PV Oil, PVN, Military Petrochemicals, Thien Minh Group Joint Stock Company Germany, ICT Company, Duc Giang Chemical, Vam Co Chemical, Hai Ha Chemical..

PCC-1 owns modern and advanced equipment

With contributions to the development of the country, PCC-1 Group was honored to be awarded noble awards by the State such as: Third-class Independence Medal in 2008, second-class in 201, certificate of assessment and implementation. comply with the requirements of the ISO 9001-2015 Standard; In 2017 and 2018: PCC-1 Group was honored to be certified as Top 500 Largest Private Enterprises in Vietnam and Top 50 Top Brands in Vietnam.

In the process of integration and development with increasing requirements for quality, progress and safety of works, PCC-1 Group has invested in modern equipment, trained human resources in depth. serving the construction and installation of four-tank warehouses, technological pipelines…. Therefore, PCC-1 has trusted and chosen Weldcom as a partner in the distribution of mechanical equipment towards the success of the project. Sustainable development for businesses.

ANH DONG Metal CNC

Located in Tan Binh Industrial Park, Tay Thach Ward, Tan Phu District, Ho Chi Minh City, ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED is known as a prestigious enterprise specializing in sheet metal processing, especially for the elevator industry. and interior decoration with more than 20 years of experience.

Starting from a small private production facility that started operating from 1997-1998, Anh Dong has made continuous efforts to assert its name and become one of the leading manufacturers of household products. Elevator construction, leading interior decoration in Ho Chi Minh City.

ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED

With his knowledge and enthusiasm, Mr. Phan Anh Tuan – Director of Anh Dong Production, Trade and Service Co., Ltd. has diligently researched and selected to invest and gradually replace old machines with new technologies. advanced technology to best meet the needs of high-quality mechanical processing of customers.

Anh Dong has trusted Weldcom to be the distributor of laser cutting machines, Yawei presses, CNC punching machines, etc. In the period from 2018 to 2021. Up to now, Anh Dong has owned a metal processing production line. $1 million worth of state-of-the-art panels capable of rapidly delivering orders of the highest quality. This has been confirmed through the success of a series of projects that Anh Dong participates in to provide products such as mixed-use buildings, office buildings, hotels, apartments to small and medium projects such as hospitals. Hospitals, family houses, factories, schools…

Anh Dong owns a modern processing production line provided by Weldcom

Anh Dong’s revenue in recent years has continuously grown at an average rate of about 50%. Right before the pandemic, the company’s revenue from mechanical processing services alone reached more than 30 billion dong.

Going up by strength and taking the prestige of product and service quality as a goal for more than 20 years, ANH DONG SERVICE TRADING PRODUCTION COMPANY LIMITED is a typical example for a private enterprise. bravery, dynamism and will surely make further strides in the sheet metal processing industry.

ATAD

ATAD is one of the typical enterprises that provide customers with a package solution including the stages of consulting, design, production, and erection of high-quality pre-engineered steel buildings and steel structures.

Since its establishment in 2004, ATAD has performed more than 3,500 projects in more than 40 countries and territories with a network of representative offices in: Myanmar, Indonesia, Thailand, Philippines, Cambodia, Sri Lanka, Bangladesh and Uganda.

ATAD currently owns more than 2200 professionally trained employees, quality management system ISO 9001: 2015; ISO 14001:2015, ISO 45001:2018 and 2 modern manufacturing plants with a total area of 211,000 m2. These two factories are one of the largest and most modern steel structure production lines in the world. Especially, ATAD Dong Nai factory, Vietnam is the first steel structure factory in Asia to achieve LEED Gold standard and the first factory office in Vietnam to achieve LEED Platinum.

ATAD’s factories have comprehensive manufacturing capabilities from the largest steel components to the smallest parts, the most complex parts to the simplest components, oversized or oversized components or Special steel structure, difficult to manufacture. To do that, ATAD cooperated with Weldcom to select products for the production of steel structures.

Some typical projects of ATAD at home and abroad: Vinfast automobile production complex, Hoa Phat – Dung Quat steel production complex, Cam Ranh international airport passenger terminal, international airport passenger terminal Da Nang International Airport, Passenger Terminal of Wattay International Airport (Vientiane, Laos), Vinh Tan 4 Thermal Power Plant Expansion…

One of the core values of ATAD Steel Structure Joint Stock Company is to constantly innovate and create to provide the best quality products and services. It is this strong effort that has helped ATAD win recognition and prestigious awards and certifications such as: Top 50 excellent enterprises, Vietnam gold star award in 2021, Engineering firm of the year 2021…

With the above efforts, ATAD is determined to become a well-known brand that is proven in the construction industry and a leading steel structure company in providing solutions for pre-engineered steel buildings and steel structures. the most effective.

MINH VIET SON Corporation

The Mechanic – Colsultant – Construction – Service Minh Viet Son Corporation was established in 1992, operating mainly in the field of civil and industrial construction: Design, Production and erection of steel buildings. Prefabricated and high quality steel structure in Vietnam – General contractor for designing and building industrial plants, installing machinery and equipment and supporting services such as Canteen, garage, security house, office …

The Mechanic – Colsultant – Construction – Service Minh Viet Son Corporation

MVS owns a factory system with an area of 8000 m2 located in Binh Duong, with a production capacity of up to 6000 tons/year, of which 500 tons of steel structures/month. Besides, Minh Viet Son also owns a complete and modern machinery line, and a staff of more than 120 professionally trained employees, meeting solutions for pre-engineered steel buildings, structural components. quality steel structures to customers quickly and efficiently.

Minh Viet Son also obtained ISO 9001: 2015 certification in the field of Design, construction of civil and industrial constructions, steel structure erection. With a high quality management system, Minh Viet Son believes in providing the best solutions, high quality products and the most perfect service for the project to customers.

Minh Viet Son factory is located in Thuan An, Binh Duong

Some typical successful projects of Minh Viet Son can be mentioned such as Livax Vietnam Factory, SST Vietnam, SML Vietnam Expanded Factory, Bandai Vietnam Factory, Logitem Vietnam Logistics Center (Tan Dong). Hiep)…

In order for the products to achieve quality and bring success, Minh Viet Son’s machine line system is a top priority. Minh Viet Son has trusted Weldcom – a leading unit specializing in providing mechanical and structural steel processing solutions nationwide.

Bruco GBH4000 – S3 smart gate welding machine distributed by Weldcom

Weldcom is pleased to be a reputable supplier accompanying Minh Viet Son with steel structure production equipment such as Horizontal Welding Gate, CNC punching machine, steel beam attachment machine… Together, we hope to bring the best products. for customers.

AMECC JSC

Formerly LISEMCO 2 Joint Stock Company, renamed AMECC Mechanical Construction Joint Stock Company since 2016, with goodwill to cooperate for mutual development, jointly bring the best values to customers through through the products and services that AMECC is currently providing such as: Processing and manufacturing steel structures and equipment, hot-dip galvanized products, construction and installation of project items, general contractor/EPC contractor civil and industrial projects.

Factory and headquarters of AMECC Mechanical Construction Joint Stock Company

Currently, the enterprise has 2 factories manufacturing equipment and steel structures with a total area of 210,000m2, and the processing capacity is about 30,000 tons/year. Along with a team of experienced and highly specialized personnel combined with modern production lines and equipment systems operating according to ISO standards, we are committed to providing products and services that meet ISO standards. good quality criteria, ahead of schedule.

“SAFETY – QUALITY – PROGRESS – EFFICIENCY” is the motto that helps AMECC to launch mechanical products with good quality, meeting all the most stringent requirements of customers. AMECC has brought products and services to a number of typical customers such as Samsung, BHI, Hyundai, Sankyu, Marubeni, Kirchner, EVN, PVN, etc.

Yawei Laser Cutting Machine supplied by Weldcom to AMECC

To achieve today’s successes, AMECC has constantly innovated technology, modern equipment for construction, invested in the most advanced production lines, meeting all the most demanding needs of the owner. private works. In the market, AMECC has trusted and cooperated with Weldcom – the distributor of mechanical equipment to serve its production.

INTECH GROUP

Vietnam Industry and Technology Group Joint Stock Company (INTECH GROUP) is a leading unit in Vietnam providing conveyors, conveyor belts, rollers, roller conveyors, intelligent conveyor systems, and systems. Advanced, cost-effective industrial automation systems and solutions, Intech’s products are standardized through years of research and development, products are thoroughly tested from processing to manufacturing. to assemble and test run.

Vietnam Industry and Technology Group

With a factory area of up to 4000m2, a more professional staff of up to 110 people, and good production capacity with complete and modern machines, Intech is a destination, as well as a trusted partner. reliable for many companies, large corporations at home and abroad.

Products of Intech Vietnam have applied the quality management system of ISO 9001:2015, which helps products and Intech Vietnam affirm its position in the domestic and export markets for the field. industrial rollers and conveyors, helping the brand conquer the world’s top fastidious markets such as Japan, Hong Kong, and Mexico.

In order for products to meet quality standards, Intech Vietnam has selected units to invest in modern machinery and technology systems to achieve the above criteria. Weldcom is a leading supplier of mechanical equipment for presses, Yawei punching machines… Along with solutions in the field of mechanical engineering in Vietnam.

Yawei press machine PBH220 distributed by Weldcom

Weldcom is one of the few suppliers that owns the strongest distribution channel today with more than 1300 agents and showroom branch system covering the whole country, Weldcom always strives to become a solid bridge, bringing new high-quality products for the Vietnamese mechanical business community.

GSB Steel

GSB Steel Structure Joint Stock Company, precursor from Trac Viet Phat Co., Ltd., was first established on July 7, 2011, After 9 years of establishment and development with the premise of experience in mechanical engineering. now make the determination to go deep into the field of steel structure.

Logo of GSB . Steel Structure Joint Stock Company

GSB . steel structure factory

Besides, GSB also focuses on investing in modern machinery and equipment to ensure output quality to meet the strict demands of the market. AMECC has trusted and wished to cooperate with Weldcom, the leading prestigious unit in the field of providing mechanical processing equipment and solutions, contributing to promoting and improving the quality of products, helping to elevate its position. of GSB is the leading steel structure brand in Vietnam.

Weldcom supplies Bruco BMC – 4000 plasma CNC laser cutting machine for GSB

With the enthusiastic support of partner companies, big investors, GSB Steel Structure Joint Stock Company has been and is constantly striving to improve in terms of organization, with high responsibility in the work of bringing the Customer interests come first.

NGAI CAU JSC

NGAI CAU BUILDING AND COMMERCIAL INVESTMENT JOINT STOCK COMPANY was established in 2004 from the predecessor as a mechanical workshop operating since 2001. The enterprise is currently a unit specializing in mechanical processing and hot-dip galvanizing of steel columns. Model for electricity industry, television poles, telecommunications.. Steel beams, collars, bolts, grounding… For transmission lines, substations Bolt anchors from M16, M24, M27, M36, M90, Transformer support Voltage and equipment for stations from 110- 220-500KV, Pre-engineered steel buildings…

Logo of NGAI CAU BUILDING AND COMMERCIAL INVESTMENT JOINT STOCK COMPANY

In particular, the company’s main business is “Manufacturing and supplying structural steel products for construction engineering, electricity, telecommunications and transportation”. In addition, Ngai Cau’s products are strictly controlled from production to release to the market and are managed according to ISO 9001: 2015.

The products manufactured by Ngai Cau always ensure quality, technical requirements, art and progress, so they are highly appreciated by investors and construction contractors. To achieve the above quality standards, Ngai Cau went to Weldcom to choose the best equipment and solutions in the mechanical processing industry for businesses.

Factory of Ngai Cau company

CPT STEEL